In this article we know about boiler efficiency meaning and formula for direct method of calculation. Also we practice with an example. What is a boiler efficiency Boiler Efficiency involves the ratio between energy output to energy input. It is a fraction of energy input that actually goes into raising steam. The formula is as […]

Author: siva alluri

Pump Related formulas | Power calculation, Total Head, NPSH, Affinity laws

In this article provided pump related formulas like fluid flow rate and velocity, power calculation, Specific Speed of Pump (Nq), Total Head, Pump Torque and temperature rise, Net Positive Suction Head, Affinity laws for pump, Pump Efficiency & Overall Efficiency of the Pump Basic required formulas for the operation of Pump Formulas regarding product while […]

Fundamental Concepts of Sugar Drying | Mechanism of Sugar Drying

General Concepts of Drying Various processing methods are there for preservation of food processing units like Freezing, canning, preserving in syrup, food irradiation, salting, vacuum packaging, dehydration or drying. Drying means removal of a liquid from a liquid/ semi-solid/ solid to produce solid product by thermal energy input causing phase change. Sometimes converts solid moisture […]

Membrane filtration technology | Types and levels of membrane filtration

In this article discussed about basic concepts of Membrane filtration technology of Micron Filtration, Ultrafiltration, Nanofiltration and Reverse Osmosis Micron Filtration | Ultrafiltration | Nanofiltration | Reverse Osmosis What is membrane filtration Membrane filtration is one of the efficient and economical way of separation components that are dissolved or suspended particles in a liquid. Membrane […]

Dextran and starch effect in sugar process | Dextranase and Amylase enzymes

This article gives a brief idea about role of Dextran and Starch in sugar process like what is dextran & starch, its effect on process house, Control measures of Dextran and Starch What is Dextran Dextran is the name assigned to a family of polysaccharides which is infrequently found in healthy sugarcane plant. Sucrose is […]

Ion Exchange Resin Process In Sugar Refinery | Basic Concepts of IER Process

The Ion Exchange Resin process (IER) are usually considered as similar to electrolytes. The IER were developed in the middle 1940’s and it is based on the co-polymerization of styrene cross-linked with divinylbenzene. Basic Concepts of Ion Exchange Resin Process for Sugar Refinery Basic Ion Exchange Process The IER system involves one ion for another, […]

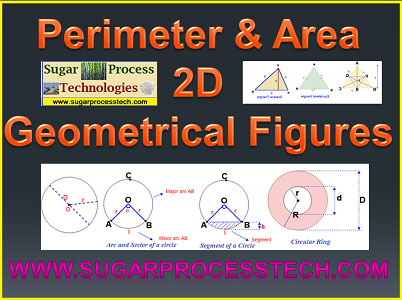

Perimeter and Area Formulas for two dimensional geometrical figures

In this page provided formulas of Perimeter and Area for two dimensional geometrical figures like square, rectangle, Rhombus, parallelogram, trapezium or trapezoid, triangle, right angle triangle, ellipse, circle, sector of a circle, segment of a circle etc Formulas for Two Dimensional Geometrical Figures Square Side for square = a & Length of diagonal = d […]

Affination Process in Sugar Refinery with Material balance Calculation

In this article discussed about factors involved in affination process of standalone refinery with material balance calculation. Material Balance of Affination Process in Sugar Refinery What is Affination Process Affination process is a first step in the sugar refinery process when high colored raw sugar taken as a input material. This process can be defined […]

Centrifugal section equipment Capacity Calculation in Sugar Industry Process

In this article explained about centrifugal section and Sugar house equipment capacity calculation for process house of sugar industry viz., Pug mills, Batch and continuous centrifugal machines, Magma mixers, sugar melter, pumps for magma & molasses, Superheated wash water system, Sugar hoppers, Sugar dryer, sugar elevator & grader. Centrifugal Section and Sugar House Equipment in Boiling […]

Mills and Diffusers Technology in Juice extraction systems of sugar industry

Sugar Plant Milling vs Diffuser process | Why Milling is favored over cane or bagasse diffuser There are two methods of cane juice extraction methodologies in Sugar Industry 1. Milling (Grinding of prepared cane ) 2. Diffusion (Extraction of juice by leaching of prepared cane with the aid of hot water) There are two variants […]