General Concepts of Drying

Various processing methods are there for preservation of food processing units like Freezing, canning, preserving in syrup, food irradiation, salting, vacuum packaging, dehydration or drying.

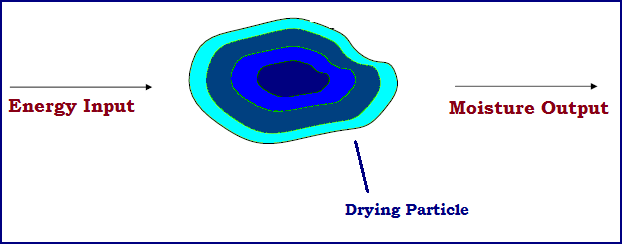

Drying means removal of a liquid from a liquid/ semi-solid/ solid to produce solid product by thermal energy input causing phase change. Sometimes converts solid moisture into vapor by sublimation process. For example freeze drying with application of heat.

The process of drying needed for the purposes of storage and preservation, reduction in cost of transportation etc.

Drying is a complex Thermal process. Drying occurs by supplying heat to the wet feedstock in the form of effecting vaporization of the liquid.

Energy input may be supplied by the following

Conduction (contact or indirect dryers)

Convection (direct dryers)

Radiation (Placing the wet material in radio frequency electromagnetic field or in a microwave)

Microwave and Radio Frequency Fields

Combination of above methods

Moisture output comes out by the following ways

Vapor diffusion.

Liquid diffusion

Surface diffusion

Capillary flow (Permeability)

Poiseuille flow

Combination of above

Most of the dryers are of the convection type with direct combustion gases or hot air as the drying medium because water is the most common solvent removed in dryers

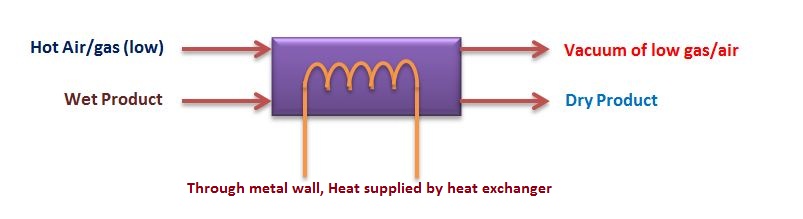

Direct Dryers (Convective): Drying medium directly contacts material to be dried and carries evaporated moisture.

Indirect dryers (Contact or conduction)

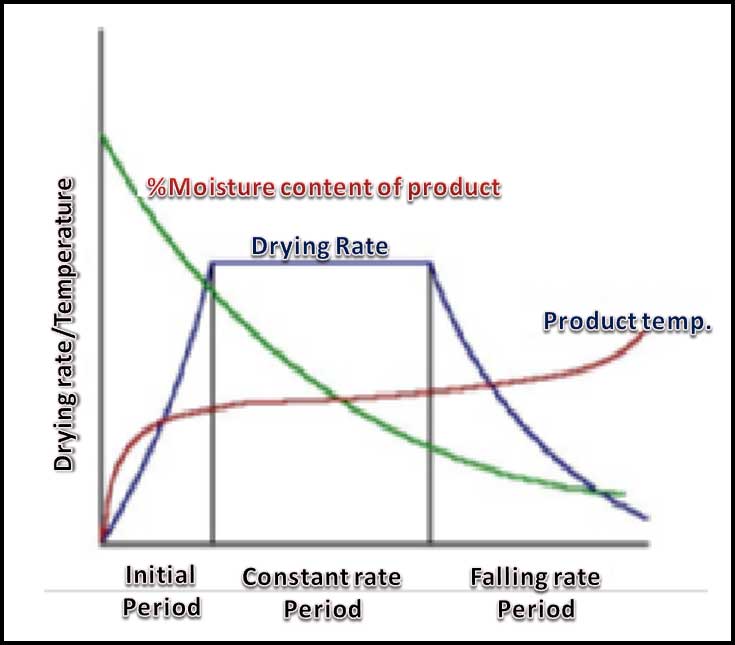

The Drying Curve

Each product having there representative drying characteristics for that product at specific pressure, temperature, velocity and conditions.

Generally, drying process occurs in three different periods or phases.

Initial period

In this first phase sensible heat is transferred to the product and the contained moisture. During this period mostly free moisture being removed with the rate of evaporation increases dramatically .

Constant rate period

In this second phase when the free moisture continue to exist on the surfaces and the rate of evaporation alters very little as the moisture content reduces. During this period, evaporation proceeds at a constant rate.

Falling rate period

In the third phase migration of moisture from the inner interstices of each particle to the outer surface becomes the limiting factor that reduces the drying rate. The film of moisture becomes exhausted and evaporation slows due to reduced surface area.

Different Industrial Dryer Types

Rotary Dryer ( Used in concentrate for smelting, cement, fertilizers, pharmaceutical, lead & zinc )

Microwave Dryers (Used in pharmaceuticals, ceramics industries, foods )

Fluid Bed Dryers ( Multi‐stage fluidized bed dryer, Vibrated Fluidized bed dryer, Spouted Fluidized bed dryer)

Vacuum Dryers – Heat Sensitive Materials

Turbo Tray Dryers

Atmospheric freeze drying

Hybrid drying

Intermittent drying

Heat pump drying

Spray freeze drying

Multi-stage dryers

Multi-processing dryers

Pulse combustion dryers

Drying mechanism of sugar

The moisture content of sugar must be reduced for two main reason.

Sugar discharged from centrifugal machine is having 0.1% – 0.4 % moisture and 60-80oC temperature. This moisture sugar is not suitable for bagging because the sugar crystal forms linkage with each other and leads to lumps formation.

Secondly higher the moisture % sugar, higher the growth of microbial organisms leading to deterioration of sugar (loss of sugar or color formation).

For the above reasons sugar should be dried to a safe limit i.e. upto 0.04 % moisture due to improve handling properties of sugar and to avoid lumps during storage.

Sugar is discharged from the centrifugal it contains water in two forms

Inherent Moisture :

Water occluded within the crystal structure. It is uncertain whether this water is in the form of occluded liquor or chemically bound as sucrose hydrates or hydrated polysaccharides forming part of the sucrose complex.

This is water contained within the crystal structure. There is no evidence so far about the migration of this moisture to crystal surface.

Included water content is not able to be measured because it is not possible to extract it from the crystal structure so it may be considered to be inert.

Surface Moisture :

Water on the crystal surface, which exists as a saturated or even initially under-saturated syrup film of a purity less than or equal to that of the crystal.

Surface moisture is the water on crystal surface and also known as free moisture. Conventional drying help in removing free moisture + bound moisture.

Moisture available on the surface of the crystal which is readily evaporate known as free moisture, while moisture that is associated with sugar crystal or trapped under amorphous sugar is known as bound moisture.

The water be attached to the surfaces of the sugar crystal and removed by evaporative drying.

After drying process, the total water content of sugar should be less-than 0.1% with the Surface water content being 0.03%– 0.05% and leaving inclusion water content having 0.07% – 0.05% of .

Total water content: Measuring this value, using the Karl Fischer method with a solvent, such as formamide, as a solvent for the sugar, the inclusion sugar content can be determined by subtraction.

Three mechanisms thus take place in sugar drying:

1) Evaporation of moisture at a rate governed by the vapor pressure difference between the film and the surrounding air.

2) Diffusion of water molecules through the surface film, driven by the concentration gradient.

3) Crystallization of sucrose molecules in the film on to the crystal surface or as amorphous sugar diluting the film and making more moisture available for removal.

After drying of sugar should be cooled to ambient temperature (35oC – 40oC) due to draw backs as follows

Hot sugar is hygroscopic in nature. If this hot sugar is bagged directly, it absorbs moisture from atmosphere during cooling operation and form lumps.

Secondly due to high temperature the rate of melanoidin reaction increases to considerable extent and stored sugar changes it’s colour to pale yellow and then blackish tinge appears.

Kind of dryer used in sugar drying process

Gross Hopper: The multitray grass hopper is generally used in Sugar Industry. The grass hoppers are generally divided into two to three parts as per the application like receiving hopper, hot air and cold air arrangements.

The grass hoppers are generally 1.2 to 2.0 meters width and 20 to 30 meters in length depends on capacity and rotated by eccentric drive having a throw of 1.0 to 1.5 inch and 250 – 300 rpm. The horizontal trough is supported on flexible strips at 60o angle to the horizontal.

Hot air (80-90oC) is blown through the trays of hot air hopper to dry the sugar up to 0.04 % moisture while cold air is blown through the trays of next hopper to cool the sugar.

Vibrative Dryer : The structure of this type of dryer is based on the vibrative conveyor. It consist of a frame of vibrative conveyor is divided in to two chambers of top and bottom by separated plates. The under chamber contains drying air and top chamber contains sugar.

The Rotary Drum Dryer : The drum dryer is a common in production plants. The rotary drum dryer is simple structure, It consist of a cylinder vessel which is set slanting 3O to 5O.

The Fluidized Dryer: It is designed and reformed on the vibrative conveyor for sugar drying. The dryer consist of three chambers. The first one is received the moisture sugar and distributed regularly on the wideness of conveyor. The second chambers which is separated by a screen with perforated holes. sugar travel on the screen, hot air is under screen. The hot air chamber distribute hot air regularly during drying. The last one is cool chamber and its structure is alike the drying chamber. This chamber is received ambient to cool dried sugar.

Thumb Rules for Sugar factory Equipment Design Sizing

Material Balance Calculation for three massecuite Boiling

Material balance of three and half massecuite boiling calculation

Overview of Refined Sugar Process

Different Methods of Decolourization of Raw melt

Syrup Clarification System and Melt Clarification System

Design Criteria of Melt Clarification System

Carbonation Process in Sugar Refinery

Ion Exchange Process for melt decolonization of sugar refinery

Color, Solids and Purity of Crystallization in Sugar Refinery Process

8 thoughts on “Fundamental Concepts of Sugar Drying | Mechanism of Sugar Drying”

SYED SABIR RAZA NAQVI

(August 23, 2021 - 6:04 am)You have briefed very concisely,it need more elaboration inclusive recently modern concept in sugar drying.

siva alluri

(September 2, 2021 - 8:26 am)It is only brief about drying concepts. Individual equipment calculations and its performance in drying system will be upload soon

Ajit Tigadi

(August 23, 2021 - 6:15 pm)How to calculate sugar drier capacity ,required air & steam

siva alluri

(September 2, 2021 - 8:24 am)Ok we will upload soon regarding the above topic

Rahul Kumar

(July 26, 2023 - 8:40 am)How to calculate capacity of cold air

Ajit Tigadi

(December 7, 2021 - 11:10 am)Good Information. But I can’t understand calculation, it is better to give calculation obout hopper & drier with example.

siva alluri

(January 2, 2022 - 9:00 am)Ok we will provide soon

Sunil Kumar

(September 15, 2022 - 4:16 am)I want to know the complete specifications about Sugar drier machines.