In this article we know about boiler efficiency meaning and formula for direct method of calculation. Also we practice with an example.

What is a boiler efficiency

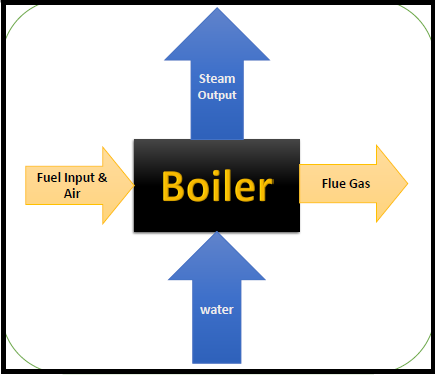

Boiler Efficiency involves the ratio between energy output to energy input. It is a fraction of energy input that actually goes into raising steam.

The formula is as follows:

Here

Energy output means heat exported or gained by the fluid of water, steam (Heat of the steam output in Kcal)

Energy input means which is heat provided by the fuel (Heat in fuel input in Kcal)

The efficiency of a boiler is mainly calculated based on the following inputs

Amount of fuel fed to the boiler furnace in Kgs/hour and its gross calorific value in Kcal/kg.

Amount of water being fed by a pump to the boiler in kgs/hr or by keeping track of Steam output from the boiler every hour in kgs/hr which can be measured using steam flow meters.

Generally, the efficiency of the boiler can be tested by the two methods which are direct method and indirect method

The Direct method means, compares how much energy one gains from the working fluid of water and steam is with the total amount of energy contained within the fuel.

The direct method means, measure the efficiency at which energy is input and energy is output

The Indirect Method means measure the efficiency is that the difference between the losses and the energy input

The Direct Method:

The direct method of the boiler efficiency is also known as “input-output method” because for this evaluation considering only the useful heat output i.e steam and the heat input (i.e. fuel).

Formula for Direct method of Boiler efficiency

Example:1

Water consumption and fuel consumption were measured in a boiler at hourly intervals. Weighed quantities of fuel were fed to the boiler during the period of operation. Simultaneously note down the steam generation during the that period. Blow down is to be avoided during the that period. By taking the measured data and calculated the efficiency of boiler as per the below examples.

Boiler Efficiency ( Considering Bagasse as a fuel)

| S.No | Description | Values | UOM |

| Heat output data | |||

| 1 | Quantity of steam generation | 64 | TPH |

| 2 | Steam Pressure | 42 | Kg/cm2 |

| 3 | Steam temperature | 410 | oC |

| 4 | Enthalpy of the steam (dry & saturated) | 773 | Kcal/kg |

| 5 | Feed water temperature | 110 | oC |

| 6 | Enthalpy of feed water | 110 | Kcal/kg |

| Heat input data | |||

| 1 | Quantity of fuel consumed | 30 | TPH |

| 2 | Gross Calorific Value of fuel | 2100 | Kcal/kg |

| Boiler Efficiency | 67.36 | % | |

| Steam to Fuel ratio | 2.13 | Ton of steam/Ton of fuel |

Example:2

Boiler Efficiency ( Considering Coal as a fuel)

| S.No | Description | Values | UOM |

| Heat output data | |||

| 1 | Quantity of steam generation | 64 | TPH |

| 2 | Steam Pressure | 42 | Kg/cm2 |

| 3 | Steam temperature | 410 | oC |

| 4 | Enthalpy of the steam (dry & saturated) | 773 | Kcal/kg |

| 5 | Feed water temperature | 110 | oC |

| 6 | Enthalpy of feed water | 110 | Kcal/kg |

| Heat input data | |||

| 1 | Quantity of fuel consumed | 15 | TPH |

| 2 | Gross Calorific Value of fuel | 4000 | Kcal/kg |

| Boiler Efficiency | 70.73 | % | |

| Steam to Fuel ratio | 4.27 | Ton of steam/Ton of fuel |

Example:3

Boiler Efficiency ( Considering Concentrated Spent wash as a fuel)

| S.No | Description | Values | UOM |

| Heat output data | |||

| 1 | Quantity of steam generation | 17 | TPH |

| 2 | Steam Pressure | 43 | Kg/cm2 |

| 3 | Steam temperature | 380 | oC |

| 4 | Enthalpy of the steam (dry & saturated) | 758 | Kcal/kg |

| 5 | Feed water temperature | 110 | oC |

| 6 | Enthalpy of feed water | 110 | Kcal/kg |

| Heat input data | |||

| 1 | Quantity of fuel consumed | 8.8 | TPH |

| 2 | Gross Calorific Value of fuel | 1900 | Kcal/kg |

| Boiler Efficiency | 65.92 | % | |

| Steam to Fuel ratio | 1.9 | Ton of steam/Ton of fuel |

The Indirect Method:

The efficiency of the boiler can be measured in the indirect method is also easily by measuring all the losses occurring in the boilers using the principles to be described.

We use indirect method to overcome the disadvantages of the direct method. In this method we have to calculate the various heat losses associated with boiler.

The efficiency of boiler can be arrived at, by subtracting the heat loss in-terms of enthalpy from the total input fuel enthalpy.

Related Articles

Need of Boiler Feed water Treatment | Boiler water treatment process

Economizer heating surface and its outlet flue gas temperature calculation

Activated Sludge Process for Wastewater Treatment | Anaerobic Digestion

ETP | Sugar industry effluent treatment plant process philosophies

Anaerobic Treatment Process for Industrial Waste Water | Anaerobic digester

Cooling tower basics calculation formulas | Cooling Tower Efficiency

1 thought on “Boiler Efficiency Calculation by Direct Method with Example”

Myint Than

(February 1, 2023 - 3:41 am)Thanks