Plantation White Sugar Manufacturing Process | Double sulphitation sugar

The Plantation white sugar is called as white sugar or double sulphited sugar. It is produced from sugar cane by the process of double Sulphitation. It is direct consumable product. The white sugar mostly produced in Asian countries.

In the manufacturing process of white sugar having four major steps

1.Cane preparation.

2.Juice extraction.

3. Juice clarification.

4. Crystallization and Centrifuging.

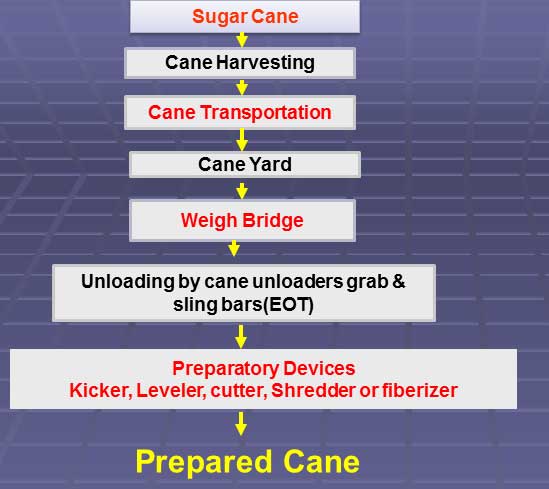

1.Cane Preparation :

The object of cane-preparation is to cut cane into short pieces without juice extraction.

The matured cane has been harvested according to both maturity test and date of plantation. The harvested cane transported to factory site. The transport system of cane should be stabilized for efficient supply of cane.

The cane unloaded by unloaders and shifted to cane carriers. The cane passes through the preparatory devices like cane leveler, cane cutter and Dis-integrator(fiberizer or shredder).

The cane leveller knives are required mainly to even cut of the layer of cane. They are arranged to work with a high clearance and in consequence leave to a large portion of uncut cane. Its is also called cane chopper or cane kicker.

The cane cutter is helps to cut the cane into small pieces of cane. It has installed before entering the dis- integrator.

The object of Dis-integrator is to complete the Preparation and Disintegration of the cane, so as to facilitate the completed extraction of juice. The dis-integrated system is called as a shredder or Fibrizer. It consists of a shaft carrying hoses to which hammers are used.

2. Juice Extraction:

The following technologies that exist today for the purpose of Juice Extraction.

- Milling Technology.

- Diffusion Technology.

- Low pressure extraction (LPE) Technology.

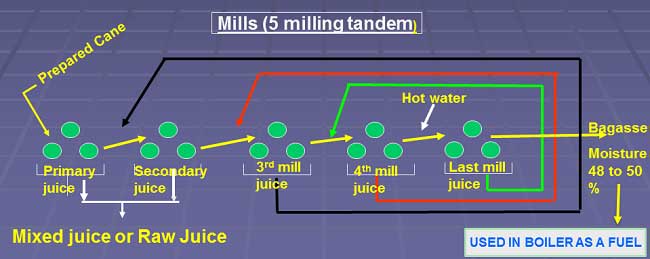

Milling Tandem:

The prepared cane is feed to mills where it is subjected to repeated heavy pressure by slowly revolving rollers and the juice is squeezed out. The bagasse coming out from the first mill is subjected to pressure by the next mills, which are arranged in a single train. According to factory capacity designed the rollers sizes and number of rollers sets. Generally following 4 milling or 5 milling tandems (rollers sets).

Hot water used for maximum extraction of juice from prepared cane . It is also called imbibition water. The cane fibers cells replaced juice with water. The imbibition water is added to the bagasse going to the last mill. The juice from last mill is added to the bagasse coming to the penultimate mill and the juice from the penultimate mill is sent to the preceding mill and so on.

Four or five stages(set of mills) are using for juice extraction in milling tandem. According to that the milling system called as 4-milling tandem or 5-milling tandem.

Finally juice collected from 1st and 2nd mill tandem. The extracted juice called as a mixed juice or raw juice and sent to process house.

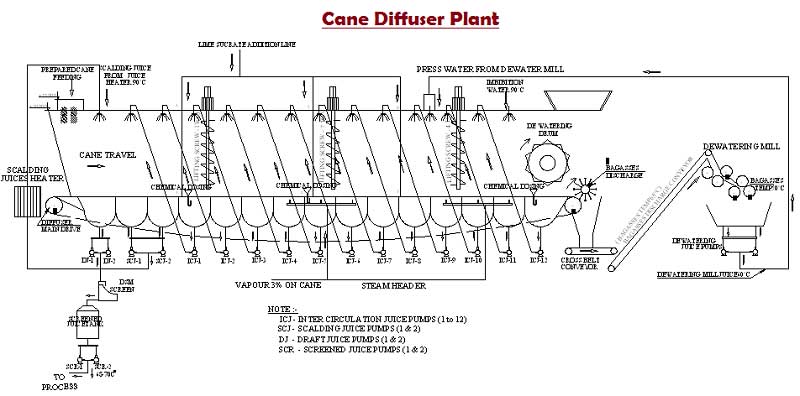

Diffusion Technology:

The prepared cane passed through the Diffuser. The diffuser system consisted of two types of technologies. They are cane diffuser and baggase diffuser.

This is a process in which water or a solution of lower concentration than the juice which the cells contain give-up to that water or solution a part or all the sugar forming the excess of concentration of their juice.

In cane diffusion, sugar extraction from cane is actually effected by rupturing the cane cell and then washing the ruptured cells with water or juice. As sugar extraction depends to a great extent on the proportion of cells ruptured and on the access of the cell contents to the extracting liquid.

Low pressure extraction (LPE):

Low pressure extraction (LPE):

The LPE system is using a train of low pressure (LP) units as main components. Although these devices resemble a conventional mill train and its operation, the process lends it self more toward the solid.

Low pressure extraction(LPE) system is a simple device and may be termed as solid liquid extractor. The prepared cane is received by first module of LPE rolls containing two pairs of fabricated rollers rotating of spherical roller bearings driven with AC electric motor through chain and sprocket. Tandem consists of 4 LPE modules followed by a three roller-dewatering mill which is mainly used to reduce moisture in bagasse.

The collected juice from juice extraction system is send to process house to produce sugar. After juice exaction the residue is called bagasse and it is sent to boiler as a fuel.

The extracted juice called depended upon the technology used for juice extraction. Generally it is called as mixed juice or raw juice or draft juice.

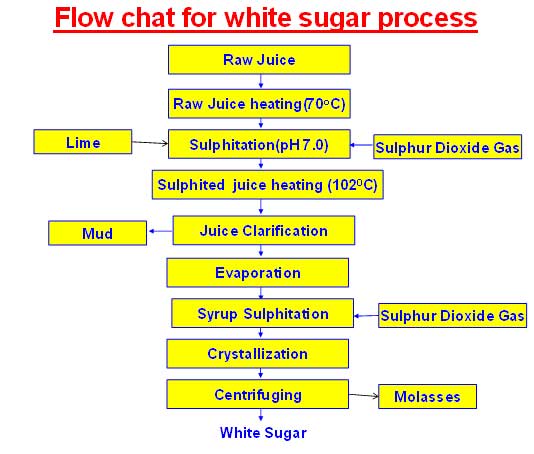

3. Juice Clarification:

In juice clarification process having the following stages.

- Juice heating

- Sulphitation

- Juice clarification.

- Evaporation of the juice

- Syrup sulphitation.

Juice Heating : Juice heating normally done by three stages. They are raw juice heating, sulphited juice heating & clear juice heating. For juice heating used different types of heaters like tubular heaters, direct contact heaters(DCH) and plate type heaters (PHE).

Heating of the mixed juice or raw juice (comes from juice extraction system) before the treatment of lime and sulphitation. Raw juice temperature maintained around 70 to 75 oC . The heated raw juice sent to reaction vessel of sulphitor.

Juice sulphitation: It a process of purification of cane juice by employing milk of lime (MOL) and sulphur dioxide(So2) gas. The juice sulphitor is called as a reaction vessel. In this vessel lime and sulphur dioxide is added and the finally maintained neutral pH of 7.0±0.1. The juice comes from the juice sulphitor is called sulphited juice.

Sulphited or Treated juice heating : After completion of reaction in juice sulphitor again juice heated upto its boiling point is called sulphited juice or treated juice heating. Sulphited juice temperature maintained around 100 to 102 oC.

Juice Clarifier : The function of Clarifier is to separate insoluble solids in Sulphited juice, which are in “flocs” by means of settling and allowing the clear Juice.

The clarification process separates the juices treated into two layers.

- The clear juice,which rises to the top surface.

- The mud ,which collects at the bottom.

The clear juice sent to evaporation system and mud sent to further juice extraction.

The settled mud in clarifier contains sugar. To extract the juice from mud used filtration technology of vacuum filters or decanters technology.

Evaporation: In the evaporation process, the concentration carried on until the percentage of solids has reached not less than 70%. The process is conducted under a system of multiple effect evaporators. That is concentrating clear juice is called syrup and its about 55 to 65 brix(concentration) and pH is varying from 6.5 to 6.8.

Syrup Sulphitation: The vessel used for syrup sulphitation process is called syrup sulphitor. The sulphur dioxide gas passed through syrup in syrup sulphitation tank till it reaches to 4.8 – 5.2 pH.

4. Crystallization and Centrifuging:

Crystallization :

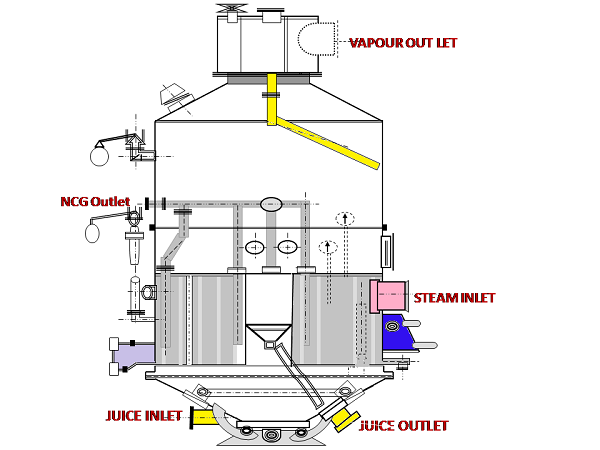

After sulphitation of syrup is goes to further process of crystallization. This syrup boiling process done by vacuum pans. The pan boiling essentially consist of the further removal of water by evaporation in single effect and crystallizing out sugar by increasing the concentration.

The function of vacuum pan is to produce and develop sugar crystals of desired size from syrup or the molasses known as mother liquor.

The Duty of vacuum Pan is

- Concentration of feed (syrup or molasses)

- Sugar Crystal Nucleation.

- Finishing the strike with tight massecuite (Massecuite means it is a mixture of sugar crystals suspended in the almost exhausted mother liquor.)

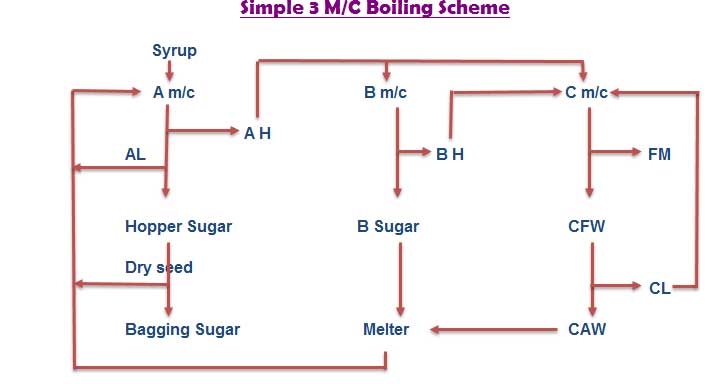

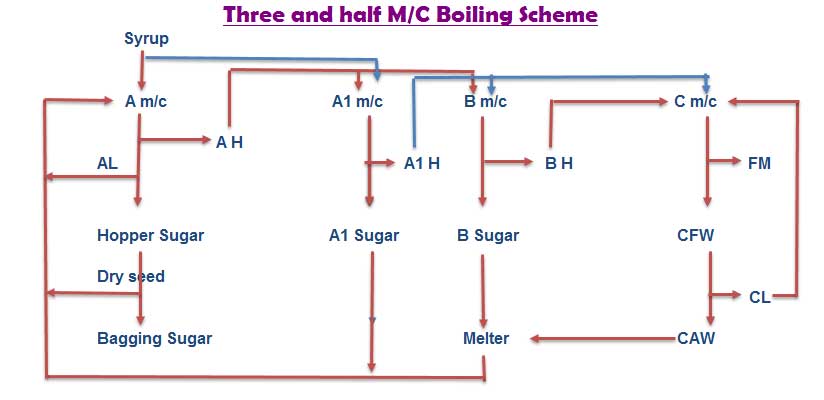

The first massecuite obtained from virgin syrup is called A-massecuite and the mother liquor separated from A-massecuite in centrifugal is called A-molasses. However this A molasses still contains a high proportion of crystallisable sugar. It is therefore collected separately and used to build second strike.

Number of bolings to be used for maximum extraction of sugar from syrup. The number of boiling mainly depends upon syrup purity. In crystallization process generally follows the massecuite boiling schemes like

- Three massecuite boiling.

- Three and half massecuite boiling.

- Four massecuite boiling.

The masecuites dropped from vacuum pans to cylindrical or ‘U’ shaped vessel equipped with slow speed stirring element. The special equipment is called as crystalliser. The massecuite sent from crystallizers to centrifugals to centrifuge the massecuite.

Centrifuging :

The machine in which crystals in the massecuite are separated from the surrounding molasses or syrup by a centrifugal force is called a centrifugal or a centrifuge.

Centrifugal machines are mostly divided in two types.

- Batch type Centrifugal machine

- Continuous type Centrifugal machine

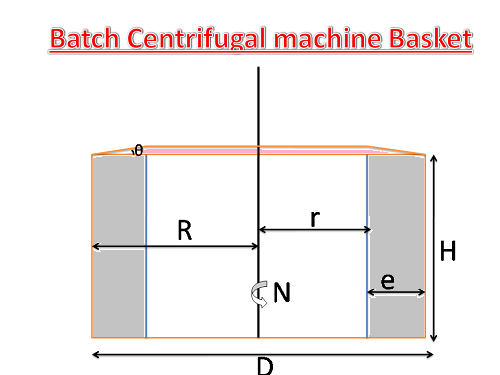

Batch centrifugal machine used for high grade massecuite ( A- massecuite) and continuous machines are for low grade massecuites (B & C massecuites).

The batch centrifugal machines takes feed in batch process. It consists of a perforated drum or basket revolving on a vertical shaft or axis called as spindle. The basket revolves within a metallic casing, which catches the molasses spun off molasses due to the centrifugal force. At the time of separation of molasses, the sugar washed with super heated wash water and dropped the sugar in hopper for drying process.

The continuous machine runs at constant speed with constant and continuous feeding of material giving constant output of sugar and molasses. The only disadvantage is the crystal breakage in continuous centrifugals due to it’s very high peripheral speed. So continuous machines are not preferred for high grade massecuite as crystal size and shape is the important aspects of sugar in market.

Sugar Drying and Cooling:

White Sugar discharged from centrifugal machine is having 0.1 – 0.4% moisture and 60-80oC temperature. The higher moisture and temperature of sugar form lumps during storage. So the sugar should be dried to a safe limit i.e. upto 0.04 % moisture and cooled up to 38 to 40oC.

The sugar drying and cooling operation are carried out with the help hot air and cold air. For sugar drying process used equipments like Grass hoppers or fluidized bed hopper or Rotary sugar drier.

The dried sugar so obtained consists of heterogeneous crystals and needs to be well sieved and graded before it is marketed. The grading of sugar done by sugar grader. The sugar crystal size classification is usually achieved by using wire mesh or perforated plate through which sugar crystal smaller than screen aperture may pass, while largest fraction is carried over the surface.

According to sugar crystal size there shall be divided into L, M , S & SS grades. Generally the crystal size

- L- Grade sugar having 1700 to 2200 micron size.

- M- Grade sugar having 1200 to 1700 micron size.

- S- Grade sugar having 600 to 1200 micron size.

- SS- Grade sugar having 200 to 600 micron size.

Specifications of Plantation white Sugar as per IS 5982:2003

| S.No. | Description | Unit | Values |

| 1 | Polarization | % min. | 99.5 |

| 2 | Colour | IU max | 150 |

| 3 | Moisture | % max | 0.1 |

| 4 | Conductivity Ash, percent by mass | % max | 0.1 |

| 5 | Reducing sugar percent by mass, | % max | 0.1 |

| 6 | Sulphur dioxide, | max. ppm | 70 |

| 7 | Lead | max. ppm | 5 |

Chemicals Used in white sugar process:

Phosphoric addition is the first step for process house. It helps to remove the non sugars in the form the precipitation. Faster mud formation and Better clarifications. The cane juice itself having phosphate content. The dosing in the range of 50ppm to 100ppm on cane or some times there is no need to addition due juice quality.

Generally it’s dosing depends upon the juice parameters and it is in the range of 50 to 100ppm on cane.

Mill Sanitation Chemicals (Di thio carbonate basis, Quaternary ammonium basis, Halogen basis) :

Biocides used in order to overcome the microbial contamination of sugar cane juice in the milling tandem. The mechanical house keeping like cleaning by hot water jet/steam washing is also helpful to minimize the microbial contamination.

The concentration that is used at the mills is usually in the range of 2 – 20 PPM on cane crushed depending upon the activity of the biocide.

Lime:

Lime is the one of the major clarification agent in this white sugar process. The important reactions in the clarification are the precipitation of calcium phosphate. Lime reacts with soluble phosphate and produces heavy tricalcium phosphate precipitate.

Generally its consumption in the range of 0.15 to 0.25% on cane.

Sulphur is used as a purifying agent in the manufacturing of white sugar.

- Neutralizes excess quantity of lime added.

- Bleaches juice by acting on the coloring matter.

- Decreases the viscosity of juice which creates problem in exhaustion of mother liquor.

SO2 is a strong bleaching agent. It bleaches the colouring matters originally present in the cane juice. It prevents or slow down the colour formation in later stages of the processing.

Generally its consumption in the range of 0.05 to 0.1% on cane.

Flocculent is used in clarifier to faster settling of juice , While using this mud takes shorter thickening time and high clarity of juice.

The dosing of flocculent is in the range of 1-5 ppm per tone of cane crushed as per clarifier design basis.

Some Related Articles

Refined sugar making process | Refined Sugar Manufacturing Process

Raw Sugar Making Process | Know About Raw Sugar Manufacturing Process

Liquid Sugar Manufacturing Process from sugar cane | Liquid Sucrose

Specialty sugar products Like Cube sugar | Candy sugar | Fondant sugars

Hi friends Thanks for reading. I Hope you liked it. Give feed back, comments and please don’t forget to share it

2 thoughts on “White sugar making process | How to make plantation white sugar”

HIMANSHU

(July 2, 2021 - 3:56 am)Four massecuite system solid balance

Bharat maruti Kshirsagar

(September 20, 2022 - 9:26 am)Pan Boiling books PDF please send