In this article discussed about basic concepts of Membrane filtration technology of Micron Filtration, Ultrafiltration, Nanofiltration and Reverse Osmosis

Micron Filtration | Ultrafiltration | Nanofiltration | Reverse Osmosis

What is membrane filtration

Membrane filtration is one of the efficient and economical way of separation components that are dissolved or suspended particles in a liquid.

Membrane filtration process is a physical separation method described by the facility to separate molecules by its characteristics and different sizes.

The membrane is a physical obstruction that depending on their physical and/or chemical properties, allows certain compounds to pass through membrane. So membrane filtration is a physical procedure for particle separation of particles by means of semi-permeable membranes.

Membranes commonly consist of a thin dense layer on top and porous support layer with that forms the actual membrane.

Membrane technology facilitates to boost product quality and at the same time bring down overall production costs.

Types of membrane filtration

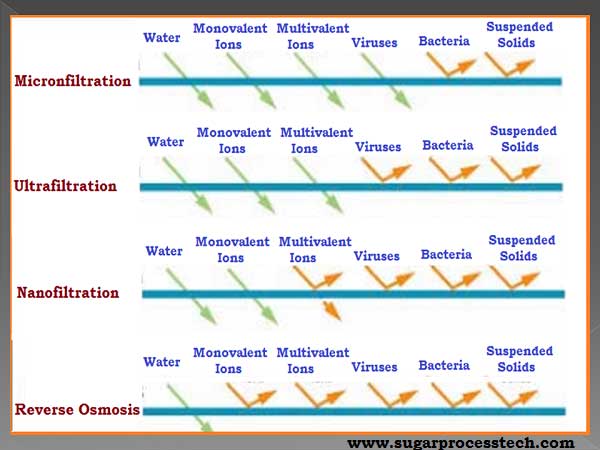

Types of Membrane filtration based on the pore size of membrane and There are 4 types of technologies and they are described as below

Micron Filtration

Ultrafiltration

Nanofiltration

Reverse Osmosis

Membrane filtration is a dynamic filtering (cross-flow filtration) process. The flow direction of the material ( liquid or gas) is horizontally through membranes but not vertically through the filter area.

Advantages and Disadvantages of membrane filtration

1) High performance

2) Simple operation and compact units

3) It occupies less space other than conventional treatment schemes

4) Membranes filtration technology can be used to separate many kinds of contaminants

5) Disinfection can be performed without chemicals

6) Membranes have to be replaced on a regular basis due to its fouling

7) Production of polluted water from reject or back washing

Microfiltration

Microfiltration is a physical separation process that removes contaminants like microorganisms from process fluids, fats and suspended solids.

Generally, Microfiltration may use in combination with other membrane technologies such as ultrafiltration, reverse osmosis or nano-filtration.

The material of construction for micro filters surface depending on the application area means they may be made from plastic, textile fabric or stainless steel. Some new technology membranes are made robust materials and large area format to provide excellent economy and extremely stable performance independent of variability in feed water.

MF membranes are capable of removing particles of more than 0.1 micron sizes

Crossflow microfiltration (MF) is a highly efficient way to remove large colloids, micro-organisms and small suspended solids from large volumes of water.

Operating pressures are lower than compared with other types of membrane filters. Typically used 1 to 2 bar working pressure and backwash and air scrubbing techniques are used for this system to minimize requirements for chemical regeneration or replacements of membrance.

Application and advantages of Microfiltration

a) Reduces silt density index (SDI) to protect reverse osmosis or nano-filtration membranes and ion exchange.

b) Removes turbidity, suspended solids, bioburden

c) This technology is capable to remove chlorine and other chemicals which may be present in feed

d) Negligible waste stream

e) Microfiltration is a stable filtrate and low chemical compared to other types of membrane filters

f) Low operating cost

Ultrafiltration

Ultrafiltration is a low pressure, cross flow separation technique used to remove very fine particles, macromolecules, colloidal particles, proteins, microbiological contaminants, and large organic molecules from the feed stream.

Ultrafiltration membranes are capable of removing particles of 0.1 to 0.01 micron sizes. All smaller molecules and dissolved salts are pass through this type of membrane. The UF membrane rejects proteins, colloids, large organic molecules and microbiological contaminants.

Reverse osmosis membranes are very sensitive to silica, colloidal particular and organic matter fouling, which results higher operating cycles and frequent replacement of membrance. Ultra filtration is the best pretreatment technology for cost effective Reverse osmosis performance. Pretreatment with UF reduces fouling and increase the life of the RO membrance.

The Ultrafiltration system works at 90% recovery. This means that 90% of the feed material will be available as permeate and the remaining 10% will carry all the rejected material that would be drained.

Applications, benefits and disadvantage include

a) The common applications of UF technology for pyrogen control in both low and high temperature distribution using both hollow fiber, pharmaceutical water processing are in pretreatment and ceramic technologies.

b) Ultrafiltration is used for such applications as metal recovery and wastewater cleaning in the field of metallurgy, separating proteins and cold sterilization in the pharmacy

c) UF system will retain particles, bacteria, viruses, pyrogens (endotoxins), colloids and large organic molecules.

d) Excellent protection for RO system when used in prefiltration treatment

e) Dissolved salts and smaller organic molecules pass freely through this ultrafiltration membranes system.

Nanofiltration (NF)

Nanofiltration is a specialty membrane process which rejects particles in the approximate size range of 0.001 micron means one nanometer, hence this membrane is termed as “nanofiltration.” Nanofiltration is a pressure-driven membrane processes.

Nanofiltration liquid separation technology operates in the realm between Ultrafiltration and reverse osmosis. It means this membrane is positioned between reverse and ultrafiltration.

When compare to reverse osmosis, nanofiltration uses lower pressures and filters with larger pore sizes. The particle size, which is retained in NF, is the size of single and divalent heavy metal ions.

Nanofilters are commonly referred to as membrane softeners because they will commonly reject the double-positively charged (i.e., calcium & magnesium) hardness ions fairly well but cannot reject the single-positive charged soft ions like sodium & potassium. Some type of NF membranes removal of monovalent ions varies between 50% to 90% depending on the material which is used for the membrane.

Nanofiltration membranes and systems are used for food & pharmaceutical and water softening applications.

Reverse Osmosis

Reverse osmosis (RO) is the finest level of membrane filtration technology to separation in liquids. The RO membranes system used an efficient separation of all dissolved salts and inorganic molecules as well as most organic compounds

Reverse Osmosis membranes are capable to separation of particles 0.001 micron (100 Daltons) sizes.

In the design and staging of Reverse Osmosis systems in single or multipass arrangements for low fouling performance, for extremely high recovery rates and stable system without the use of chemicals.

Advantages of RO system

a) RO system is a compact and modular design

b) No added chemicals

c) Maximum efficiency in throughput

d) We can get high recovery rates of 95%

e) Very high rejection rates producing high purity filtrate

Please go through the below link for more information regards Reverse Osmosis system

Levels of membrane separation

| S.No | Type of membrane | Size of Particle | Typical Operating Pressure in Bar | Type of Particle |

| 1 | Microfiltration | > 0.1 micron | < 2 | Large colloids, micro-organisms and suspended particles, |

| 2 | Ultra filtration | 0.1 to 0.01 micron | 1 to 10 | Proteins, colloids, large organic molecules and microbiological contaminants – Macro molecules, |

| 3 | Nan filtration | 0.01 to 0.001 micron | 5 to 35 | Double-positively charged (i.e., calcium & magnesium) hardness ions. Micro molecular organic compounds |

| 4 | Reverse Osmosis | < 0.001 µm | 15 to 150 | Dissolved salts and inorganic molecules |

Related Articles

Mills and Diffusers Technology in Juice extraction systems of sugar industry

ETP | Sugar industry effluent treatment plant process philosophies

Activated Sludge Process for Wastewater Treatment | Anaerobic Digestion

Anaerobic Treatment Process for Industrial Waste Water | Anaerobic digester

CSTR Digester | Anaerobic Treatment for Raw Spent wash in Distillery

Pump Power Calculation Formula | Specific speed of a centrifugal pump