Tubular juice heater design calculation with online calculator

The shell and tube multipass tubular juice heater consists of an assembly of tubes, the juice circulates through the tubes, and the vapour outside them. The juice to pass a certain number of times from bottom to top and from top to bottom of the heater by restricting the juice each time to a few of the tubes.

There are two principal designs of tubular juice heaters, the horizontal and the vertical, both are use in sugar Industry. The Vertical juice heaters are preferred because they occupy less floor space, are subject to less formation of scales and provide better facilities for cleaning.

Shell and Tube Multipass Heat Exchanger Design | Tubular juice heater design calculation with online calculator

Construction Parameters of Tubular Juice heater:

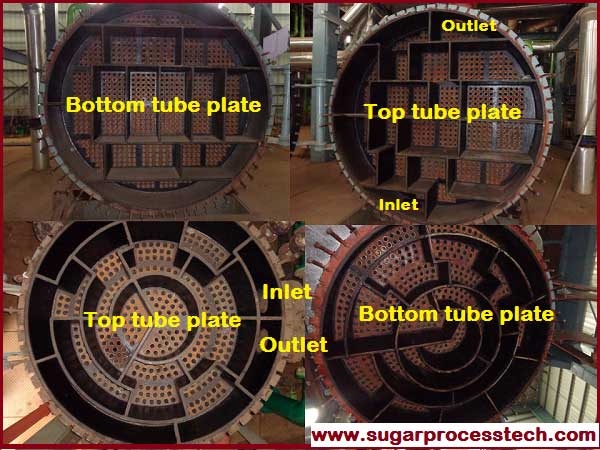

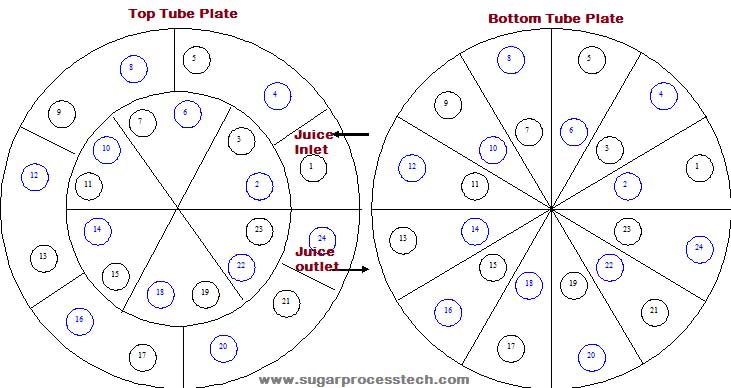

- The cylindrical shell containing the tube plates is extended at each end beyond the tube plate, the extended portion being divided into compartments by baffles.

- The heated media (juice) circulates through out tubes and heating media (vapours) circulated on shell side.

- The first compartment which is for juice inlet and last compartment which is for juice outlet. These two are located upper portion each compartment provides for two passes of upward and downward flow. If there are 22 tubes per pass, for example, there will be 44 tubes for each compartment, 22 for upward and 22 for downward flow.

- The shell and doors are material of construction( MOC ) consider as MS mild steel and for tube generally used Brass or SS304.

- Heat transfer coefficient plays an important role to find the heating surface calculation of the heater.

- Number of passes always should be consider even number.

- The legment of the tube plate generally consider 12mm for juice heater design.

- The prapotional factor of the tubes consider 0.6 to 0.8 for multiple passes of heater.

- Air vents and drain cocks shell be provide for each compartment.

- Juice velocity in tubes generally consider from 1.6 t0 2.0 m/sec. And heating media velocity consider as per the bleed vapour. The lower velocity of the juice in heater would foul more rapidly. For the high velocities the passage of the juice through the heater causes a marked pressure drop, which rapidly becomes prohibitive.

- Tubes have a diameter in the range of 38 to 50 mm. Tube lengths may vary between 3 m and 6 m. Longer tube designs lead to lower pressure drops at the same liquid velocity because of the reduced number of passes.

- The temperature different between outlet of the heated media(Juice) and condensate of the heating meadia(vapour) is called approach of the heater.

- The approach temperature depends upon heating media (bleed vapour), type of heater (Dead end or dynamic type). It is vary from 5 to 12oC.

- For dynamic or vapour line juice heater the approach temperature comes upto 5 to 8oC. For turbine exhaust or 1st bleed vapours the approach comes 5 to 8oC. The lower bleed vapours the temperature approach taken 8 to 12oC

- Efficient removed to be required for condensate water and non condensable gases.

- Condensate outlets from the heater should be sufficient to ensure that the velocity of flow of the water does not exceed 1 m/s.

- The non condensible gases (NCG) removal purpose to be provide for every 10m2 heating surface area required minimum 1cm2 area.

- Heaters are tested, according to the intended permissible working pressure is 2.5 bars on shell side means vapour side and 6 bars on tube side means juice side.

- The dynamic type tubular juice heater having outlet vapour line along with the inlet vapour line. So the heating media having two connections of inlet and outlet. The heat transfer coefficient is higher in the dynamic type heater due vapour sweeping effect.

- In the dynamic type tubular juice heater outlet vapour line dia design for 70 to 100% on total vapour demand. So for the inlet vapour line dia designed for 70 to 200% on total vapour demand of the juice heater.

Heat Transfer Coefficient:

To know about fundamental concepts of heat transfer coefficient purpose go through the below link.

Heat transfer coefficient for shell and tube heat exchanger.

HTC depends upon

- Thermal conductivity of the tube metal.

- Diameter and the thickness of the tube.

- Clean lines of the tube surface from the inside and outside.

- Density, Velocity, viscosity & temperature of Juice to be heated.

- Efficient removal of condensate water and non- condensable gases.

- Scale formation and its thickness over the tube surface

For complete information of Heat transfer coefficient calculation purpose please go through the below link

Juice Heater Heat Transfer Coefficient Calculation.

Thermal conductivity for different metals

Material Thermal conductivity in Kcal/m2/hr/oC

Copper 324.74

Aluminum 177.04

Brass 84.30

M.S 38.70

S.S 14.00

For simplification of the finding heat transfer coefficient (HTC) purpose our technologist proposed number formulas. Out of that the below mentioned formula is most popular for dead end type juice heaters. This formula have taken from HANDBOOK OF CANE SUGAR ENGINEERING by E. HUGOT.

K = 6 x Tv x [U / 1.8] 0.8

This formula applicable only for dead end type sugar industry juice heater design.

Here K = HTC in Kcal/m2/hr/oC

Tv = vapour temperature in oC

U = Velocity of juice in m/sec

Heating Surface calculation of tubular juice heater

Fundamental formula :

Heat received by heated media(juice) = Heat rejected by heating media( vapour)

Q =M x Cp x ΔT = K x S x ΔTm

Where

Q = Heat transferred in kCal/hr

M= Quantity of material to be heating or cooling in kg/hr

Cp = Specific heat of material in Kcal/kg/oC

ΔT = Temperature difference from inlet to outlet of the heated material in oC

S = Heat transfer surface area in m2

ΔTm = LMTD = Log Mean Temperature Difference

K = Overall heat transfer Coefficient Kcal/m2/hr/oC

Ti / To = Hot fluid inlet/outlet (vapour)

ti / to = Cold fluid inlet/outlet (Juice)

ΔT = to – ti

ΔTinlet = Ti – ti ( Co current Flow)

ΔT outlet = To – to (Co current Flow)

Here Heating media is vapour and utilize only the latent heat only so heating media inlet and outlet temperatures are same. So it is to be take as Tv

Design formulas of shell and tube multipass heater

Here we calculate with consider with the example.

To find the heat transfer coefficient by using above formula i.e K = 6 x Tv x [U / 1.8] 0.8

or to be calculate as per the standard formulas like below

Shell and tube Heater Heat Transfer Coefficient Calculation.

According to the heat transfer coefficient we can heating surface easily by the above formula.

| S.no | Particulars | Sign and formulas | Values | UOM | |

| Data to be required for calculation | |||||

| 1 | Crushing rate | TCH | 210 | TCH | |

| 2 | Juice % cane | P | 102 | % | |

| 3 | Velocity of Juice | Vj | 1.8 | m/sec | |

| 4 | Density of juice | ρ | 1.06 | gm / ml3 | |

| 5 | Tube OD | OD | 45 | mm | |

| 6 | Tube Thickness | Tk | 1.2 | mm | |

| 7 | Tube ID | ID | 42.6 | mm | |

| 8 | Tube length | L | 4000 | mm | |

| 9 | Specific heat of juice | Cp | 0.9 | Kcal/Kg/oC | |

| 10 | Legment | Lg | 12 | mm | |

| 11 | Vapour inlet temperature | Tv | 85 | oC | |

| 12 | Juice inlet temperature | ti | 60 | oC | |

| 13 | Juice outlet temperature | to | 75 | oC | |

| 14 | Tube plate thickness | Tb | 25 | mm | |

| 15 | Velocity of vapour | Vv | 40 | m/sec | |

| 16 | Heater Heating Surface | S | 250 | m2 | |

| 17 | Velocity of condensate | Vc | 1 | m/sec | |

| 18 | Proportional factor | β = 0.7 to 0.8 | 0.7 | ||

| 19 | Latent heat of vapour |

|

548.24 | kcal/Kg | |

| 20 | Specific volume of vapour | μ | 2.83 | M3/kg | |

| Calculation part | |||||

| 1 | Number of tubes per pass | ||||

| Volume of the juice | M = (TCH x P) / ( ρ x 3600) | 0.0561 | M3/sec | ||

| Area of the one tube | A = 0.785 x ID2 | 0.0014 | M2 | ||

| M / ( A x Vj) | 21.89 | tubes/pass | |||

| i.e | 22.00 | ||||

| 2 | Number of the tubes | ||||

| Mean Dia | Dm = OD – Tk | 43.8 | |||

| Effective tube length | L m = L – 2 x Tb – 2 x 5 | 3940 | |||

| Number of the tubes | N t = S / ( π x Dm x Lm ) | 461.36 | |||

| i.e | 462.00 | no.s | |||

| 3 | Number of Passes | n = Nt / tubes per pass | 21.00 | ||

| 3 | Number of passes should be always taken even number ( n ) | 22 | |||

| As Per Even number of passes Heater parameters to be calculated | |||||

| 4 | No. of compartments | Top side = n/2 +1 | 12 | ||

| Bottom side = n/2 | 11 | ||||

| 5 | Actual number of tubes | Nt = n x tubes per pass | 484 | no.s | |

| 6 | Actual heating surface | S = π x Dm x Lm x Nt |

262 | m2 | |

| 7 | Actual velocity | Vj = M / Area of one pass | 1.79 | m/sec | |

| 8 | pressure drop across the juice heater | 0.0025 x n x Vj2 x ( L/ ID +3) | 17.10 | MWC | |

| 9 | Tube plate dia | ||||

| Pitch | Pt = OD + Legment + Tube Tolerance(0.5mm) + Hole Tolerance(0.1mm) | 57.6 | |||

| Tube plate Area | At = 0.866 x Pt 2 x Nt / β | 1.99 | m2 | ||

| Take 10% extra | 2.19 | m2 | |||

| Tube plate dia | Dt = SQRT ( At / 0.785) | 1668 | mm | ||

| 10 | Dia of juice inlet pipe | ||||

| Area Aj = M / Vj | 0.031 | m2 | |||

| Dj = SQRT ( Aj / 0.785) | 0.199 | mtrs | |||

| i.e | 200 | NB | |||

| 11 | Vapour inlet Dia | Qj x Cp x ΔT = W x λ | mtrs | ||

| Qj = TCH x P x 1000 | 214200 | Kg/hr | |||

| ΔT = to -ti | 15 | oC | |||

| W = weight of the vapour | 5274.515 | kg/hr | |||

| Qv = W x μ /3600 | 4.146 | M3/ sec | |||

| Av = Qv / Vv | 0.104 | m2 | |||

| Take 10% extra | 0.114 | m2 | |||

| Dv = SQRT ( Av / 0.785) | 0.381 | mtrs | |||

| i.e | 400 | NB | |||

| 12 | Condensate pipe Dia | ||||

| Qc = weight of the condensate = W | 0.00147 | M3/sec | |||

| Ac = Qc/ Vc | 0.00147 | M2 | |||

| Take 50% extra for free removal | 0.00220 | M2 | |||

| Dc = SQRT ( Ac /0.785) | 0.053 | mtrs | |||

| i.e | 75 | mm | |||

| 13 | NCG pipe line dia | ||||

| Cross section area of pipe | For every 10m2 Heating surface required 1 cm2 area to be required ( An ) | 26.23 | cm2 | ||

| SQRT (( An/4) / 0.785) | 2.89 | cm | |||

| NCG pipe line dia | 4 no.s NCG points and each having | 32 | mm | ||

| 14 | Calendria shell thickness | (P* Di / (2*F*J – P) ) + C | |||

| Maximum allowable pressure | P (Hydraulic test pressure) | 3 | kg/cm2 | ||

| ID of the Juice heater | Di | 1668 | mm | ||

| Allowable stress | F | 1400 | kg/cm2 | ||

| Welding Joint efficiency | J | 0.75 | |||

| Corrosion allowance | C = 1.5 for calendria shell | 1.5 | mm | ||

| Calendria shell thickness | 3.89 | mm | |||

| Say | 4 | mm | |||

| But as per standard specification 12mm for longitude of equipment | |||||

| 15 | Tube plate thickness | f x G x SQRT((0.25 x P)/F) + C | |||

| Corrosion allowance | C = 3.0mm for tube plate | 3 | mm | ||

| Allowable stress | F | 1400 | kg/cm2 | ||

| Maximum allowable pressure | P | 3 | kg/cm2 | ||

| Modulus factor for MS sheet | Es | 2100000 | kg/cm2 | ||

| Modulus factor for SS sheet | Et | 1900000 | kg/cm2 | ||

| ID of the shell | G | 1668 | mm | ||

| Thickness of the shell | ts | 12 | mm | ||

| Thickness of tube | tt | 1.22 | mm | ||

| OD of the tube | do | 45 | mm | ||

| Do = OD of the calendria sheet | Do = ID + 2 x shell thickness | 1692 | mm | ||

| Number of tubes | Nt | 484 | no.s | ||

| K | K =( Es x ts x (Do -ts)) /(Nt x Et x tt x(do -tt)) | 0.862174 | |||

| f = safety factor | f = SQRT ( K / (2 + 3K)) | 0.433567 | |||

| Tube plate thickness | 19.74 | mm | |||

| But as per standard specification 25mm for tube plate | |||||

| 16 | Thickness of the cover plate | tc = Gc x SQRT ( K x P /f ) + C.A | |||

| ID of the shell | Gc | 1668 | mm | ||

| For flat joint | K = 0.3 | 0.3 | |||

| Design Pressure | P | 3 | kg/cm2 | ||

| Allowable stress | f | 1400 | kg/cm2 | ||

| Corrosion allowance | C = 1.5mm for cover plate | 1.5 | mm | ||

| Thickness of the cover plate | 43.79 | mm | |||

| But as per the Indian practice to given 32mm cover plate with adequate stiffening is sufficient | |||||

Tubular juice heater online calculator

Some related articles

Formulas for Design Direct Contact Heater (DCH) with Online calculation Sheet

Condensate Receiving Tank Design Calculation | Condensate Mound | Condensate Receiving & Condensate Flash Recovery tank design

Condensate or Duplex Heater (Liquid- Liquid Heater) heating surface, number of tubes, tube plate dia, pressure drop calculation formulas with online calculation sheet.

Heat Transfer Coefficient of Liquid -Liquid Tubular Heater Calculation| How to find Condensate Juice Heater Heat Transfer Coefficient Calculation

Hi friends Thanks for reading. I Hope you liked it. Give feed back, comments and please share it.

12 thoughts on “Shell and Tube Multipass Heat Exchanger Design | Tubular juice heater”

Neeraj kumar rajput

(October 20, 2017 - 4:52 pm)Sir i want the formula of heat transfer coefficient of vapour line juice heater and plate type juice heater sir please answer shortly

siva alluri

(October 21, 2017 - 1:08 pm)Ok Neeraj kumar rajput,

We will publish that topic soon

Akshay Kudache

(October 24, 2017 - 5:12 am)Very thankful to you. I understand very easily about juice Heather and their calculations..

Akshay Kudache

(October 24, 2017 - 5:16 am)I want to know about Heating surface, capacity calculations of DCH and plate type heat exchanger..

siva alluri

(October 24, 2017 - 1:48 pm)For DCH calculation please go through the link :

Formulas for Design Direct Contact Heater (DCH) with Online calculation Sheet

For PHE purpose we will publish article soon.

Surendra singh

(May 13, 2018 - 5:33 am)Thanks sir,to giving very helpful knowledge

siva alluri

(May 13, 2018 - 4:30 pm)Thank you very much Mr.Surendra singh

Prabu

(July 14, 2018 - 6:00 pm)Sir,

I want know about 1 pass shell and 6 pass tube heat exchangers. Please send its pictures both sides of tube sheets and dish ends

pradeep

(June 1, 2020 - 6:40 am)a juice heater having internal length over tube plate “L” number of tubes per pass “N” the effective diameters of the tubes “D” number of passes “n” then what will be the heating surface of the juice heater.

sir please solve this problem

siva alluri

(June 21, 2020 - 10:29 am)S = π x Dm x Lm x n

Here

S = HS in m2

Lm = effective tube lenght in m

Dm = Mean dia in m

n = total number of tubes

Sumit pandey

(June 12, 2022 - 11:39 am)Respected sir,Please tell me

No. of hole?

Plate 2 MTR X.6 mtr, hole pitch- 20mm ,

Sagar

(May 13, 2023 - 10:56 am)What MOC used for manufacturing of top tube plate and bottom tube plate of raw juice heater of sugar factory?