Formulas for Batch Centrifugal Machine Capacity and Gravity Factor with Online Calculator

The batch centrifugal machines have been using to handle white and refined sugar massecuites as well as for affination of raw sugar in the sugar refineries.

The batch machines were fully satisfying the sugar industry requirements for high sugar quality such as: low color, no lumps and low residual moisture content.

The purpose of this article is to evaluate the batch centrifugal machine capacity and its gravity factor

Parameters to be required for calculation:

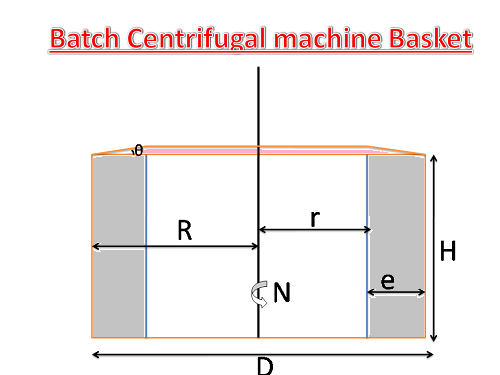

Basket Shell Internal Diameter in meters = D

Thickness of the massecuite in meters = e (Generally “e” value taken 0.14D for theoretical and 0.12D for practical)

Basket top plate angle to horizontal level in Deg.= θ (Generally this value having 5deg.)

Height of the basket in meters= H

RPM of the basket (maximum RPM in Cycle) = N

Time required for one cycle in sec = T

Density of the massecuite in gm/ml = S

Formulas for Calculation :

Volume of the massecuite per cycle in M3 (M3/cycle) = V = π e[ H(D-e) + e tanθ ((3D-4e)/6)]

No. of cycles per hour (cycle/hr) =C =3600/T

Capacity of the machine (Theoretically) (Q)

Q = C x V in M3/hr (M3/cycle x Cycle/hr)

=Q x S in tons/hr

But in practically calculating the capacity of machine takes the following considerations.

1. Take 1 to 2 empty cycles during in an hour (Depends on massecuite condition) so consider one empty full cycle in total cycles per hour.

2. While charging the massecuite is always purged, spelling out some molasses such that creating space for further massecuite. This is called purging capacity. It is 10% more than theoretical capacity.

Capacity of the machine (Practically) =Q

[(C-1) x V] x 1.1 in M3/hr

Q x S in tons/hr

Empty Basket Shell Radius in mtrs = R = D/2

Basket Shell Radius with massecuite in mtrs = r = R-e

Mean Equivalent Radius in mtrs = Rm = 2/3 [(R3 – r3) / (R2 – r2)]

Gravity factor = G = Rm x 1119 x (N / 1000)2

Gravity factor (General formula) = G = D x N2 / 1800

Explanation for gravity factor formula

Gravity Factor = Centrifugal force / Gravitational force

= m x Rm x w2 / m x g.

Where Rm is M.E.R. and

w = angular velocity = 2 π N /60 g = 9.8 m/sec2

Gravity Factor =[ Rm . X 1 X (2πN / 60 )2 ] / 9.8

= Rm x 1119 x (N / 1000)2

Online Calculator to find Batch Centrifugal Machine Capacity and Gravity Factor

Please click here

Some Related articles:

Phosphoric Acid(H3PO4) in sugar process industry and online calculator.

Super heated wash water system in batch centrifugal machines with online calculator.

Definitions in Steam Properties and Online Steam Table

Sugar industry Job vacancies Information | Job Vacancies in Sugar Industry.

Sugar Industry Related Important Websites | sugar Technology.

Sugar Tech | Sugar Technology related articles .

Sugar Industry Equipment Design and Drawing Online Calculations.

Thumb Rules for Sugar factory Equipment Design Sizing.

Hi friends Thanks for reading. I Hope you liked it. Give feed back, comments and please don’t forget to share it

24 thoughts on “Batch Centrifugal Machine Capacity and Gravity Factor Calculation”

Awanish kumar

(May 8, 2017 - 9:21 am)How you are converting that volume into kg/charge

Volume of the massecuite per cycle in M3 = = π e[ H(D-e) + e tanθ ((3D-4e)/6)]

No. of cycles per hour =C =3600/T

Capacity of the machine (Theoretically) = Q = C x V in M3/hr

=Q x S in tons/hr

& Gravity factor = G = Rm x 1119 x (N / 1000)2

Is not coming accordingly.

Please suggest.

siva alluri

(May 9, 2017 - 2:05 pm)Thank you for your commenting sir

Explanation for above given default example in calculator

Brijendra singh

(May 27, 2017 - 6:12 pm)How much Gravity factor for continuous and batch type

Akhileshwar Shukla

(September 2, 2020 - 11:47 am)What are gavity factor for A batch type ,B continuous , C continuous. c-1 continuous and CAW continuous centrifugal machine

NPSINGH

(November 13, 2017 - 12:47 pm)NICE

Nausheen

(December 15, 2017 - 9:00 am)Hello sir,

The calculations are very helpful.

Do you have the data and calculations for continuous centrifugals and those for the drying section?

siva alluri

(December 15, 2017 - 4:02 pm)Thank you for your appreciation

we published soon regarding this top

Ara

(December 18, 2017 - 7:55 am)Hello Sir,

your calculation is very helpful. Since i have study about the centrifugal for the sugar processing, i need to explain about the calculation in details. I have try using your calculation and i got the answer, but when i calculate manually, it is too different. Could you help me ?

ARUN KUMAR PAL

(February 9, 2018 - 7:52 am)very good ormula.

thanks.

B. N Amarendra

(March 31, 2018 - 1:36 pm)sir, Pl tell me about massecuite reheater design calculation

siva alluri

(April 2, 2018 - 4:41 am)We Will publish soon

Shubham sadalage

(July 7, 2018 - 9:05 am)HOW TO CALCULATE CENTRIFUGAL MACHINE SCREEN OPENING

siva alluri

(July 12, 2018 - 1:43 pm)It is very simple

1. Find the hole dia of the screen – i.e mesh size ex: 0.06 (60 micron) or 0.09 ( 90 micron)

2. Find the no of holes per sq.cm.

3. Find the perforated area of the each segment of the screen and calculate total area in sq.cm

Now we can find the screen opening area

Santosh Kumar Bakkoli

(September 23, 2018 - 4:10 am)Sir I m centrifugal mate batch machine Conti machine parts name

Shyam Borade

(February 18, 2019 - 1:21 pm)Nice. Information

I have a dout sir,

Can you tell me how calculate blower capacity for centrifugal machine ??

siva alluri

(February 20, 2019 - 2:55 pm)Ok we will provide soon

Faisal Ghouri

(January 6, 2020 - 8:06 am)Sir!

how we can calculate continous centrifugal capacity.

vitthal talawar

(January 26, 2020 - 11:01 am)sir i m centrifugal operator tell me centrifugal machine parats name

Ajay Singh

(February 15, 2020 - 5:15 pm)plz provided the calculation of FBD .its also screen size

Mahesh prasad

(August 26, 2021 - 8:30 am)What is gravity factor of centrifugal machine plese explain in simple way only description not calculation

siva alluri

(September 2, 2021 - 8:21 am)Gravity factor is the ratio between the centrifugal force and gravity. The effect of various centrifugals is compared by a ratio of centrifugal force exerted on the material to that of gravity. The centrifugal force is usually expressed as the number of times it exceeds the force of gravity and this has led to the term Gravity factor

vijau gaur

(September 3, 2021 - 8:12 am)Sir,

how can we calculate gravity factor of continuous centrifugal machine. dia of machine vary form top to bottom so can we take mean dia of continuous machine.

Nadeem Mansur Nadaf

(August 21, 2022 - 2:39 am)Hor air blower capacity

Radiator capacity

Rasoul majidi

(February 19, 2024 - 6:35 am)Dear sir how we calculate power for batch centrifuge sugar