Formulas and design parameters in Robert Evaporator Design with online calculation sheet

The object of evaporation may be to concentrate a solution containing the desired product or to recover the solvent. Sometimes both may be accomplished. Evaporator design consists of three principal elements: heat transfer, vapor-liquid separation, and efficient utilization of energy.

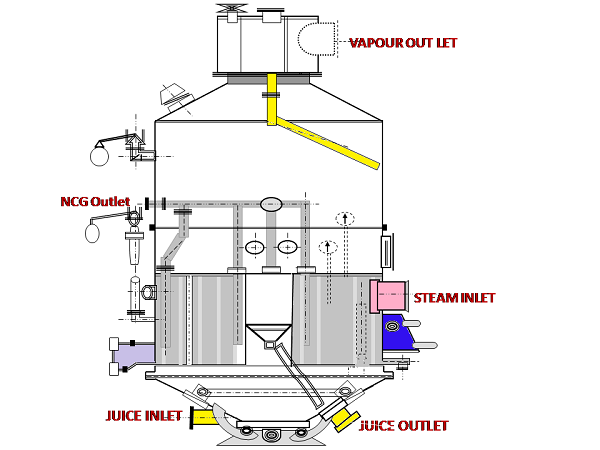

In our sugar industry the solvent is juice, heat is supplied by condensing steam, and the heat is transferred by indirect heat transfer across metallic surfaces.

Types of Evaporators:

- Robert type natural circulation evaporator.

- Long tube vertical raising film evaporator (Kestner)

- Long tube vertical falling film evaporator (FFE)

- Plate type evaporator.

- Thin film evaporators, high viscous liquid

- Inclined tube evaporators

- Horizontal tube evaporators.

- Flash evaporators.

- Compact evaporators.

The first three type of evaporators are used in Sugar Industries and recently also use the plate type evaporator.

In this article mainly discussed about Robert type evaporator body design criteria.

Steps in calculation of evaporator design:

-

Number of tubes (N ):

- Mean dia of the tube ( Dm) in mtr = Tube OD- Tube Thickness ( In some designers also take ID of the tube in the place of mean dia.

- Effective Length of the tube ( L ) = Tube length – 2(Tube plate thickness)-2(Tube expansion allowance)

- Number of tubes = Heating surface / π x Dm x L.

- The thickness of the tube generally take for juice heaters and for evaporator 18G and for pans take 16G. ( 18g = 1.22mm , 16g = 1.625mm, 14g = 1.8mm).

-

Tube plate & Downtake dia :

Area occupied for tubes in tube plate :

- Tube Pitch (P ) = OD of the tube +Legment of the tube + tube clearance+hole clearance

- proportional factor(β) = Generally β value taken for multiple pass(i.e Juice heaters) 0.6 to 0.8 and for single pass(l.e evaporators) 8 to 1.0.

- Take extra dia in percentage on area occupied for tubes in tube plate for stay roads arrangement, free withdrawal of condensate and noxious gases removal purpose. while providing the multiple down design than this percentage may go higher side. Its value lies in the range 10 to 20% on area occupied for tubes.

- Tube plate area required for tubes only ( AT ) = (0.866 x P2 x N /β) x %extra

- Tube plate dia required for tubes only = SQRT ( AT x 4/π )

Dia of the down take :

- The central well or peripheral downtake is often utilized to collect the concentrated juice in order to remove it from one vessel to the following vessel.

- According to peter rein down take dia consider less than 25% of the tube plate dia.

- According to E. Hugot The diameter of the centre well varies from ¼ to ⅛ of the interior diameter of the vessel.

- Certain manufacturers replace the centre well by a lateral well or by a series of down takes of small diameter distributed over the calendria (Multiple downtakes).

- From the above generally downtake dia take 20% on tube plate.

- Dia of the single downtake = Tube plate dia for tubes x % of downtake on tube plate.

- Dia of the central downtake in multiple down takes design = SQRT [(Area of the single downtake – Total area of peripheral down takes) x 4/π )] .

The final required tube plate diameter.

Final Dia of the tube plate = = SQRT [(Area of the Tube plate for tubes + Downtake area) x 4/π )] .

-

Dia required for vapour inlet & Dia of the Calendria in radial steam/ vapour entry

Dia of the Vapour Inlet :

Number of steam/ vapour entries will take according to heating surface of the body, diameter of the body and performance of evaporation.

- Vapour required for calendria = Heating surface x Evaporation rate of the body.

- Area required for the each vapour entry (m2) = Volume of the vapour in each (M3/sec) / Velocity of vapour.

- Dia of the each steam entry = SQRT [ (Area required for the vapour entry / Number of vapour entries) x (4/π ) ]

As Per Hugot given Evaporation Rate of The Several Vessels of a multiple effect working under the condition of temperature drop from 120oC to 55oC

| Triple Effect | Quadruple Effect | Quintuple Effect | ||||

| Kg/m2/hr | Lb/Ft2/hr | Kg/m2/hr | Lb/Ft2/hr | Kg/m2/hr | Lb/Ft2/hr | |

| 1st effect | 53 | 11 | 37 | 7.6 | 28 | 5.7 |

| 2nd effect | 48 | 9.8 | 35 | 7.2 | 26 | 5.3 |

| 3rd effect | 43 | 8.8 | 32 | 6.6 | 25 | 5.1 |

| 4th effect | 28 | 5.7 | 25 | 5.1 | ||

| 5th effect | 17 | 3.5 | ||||

Evaporator Bodies Vapour Velocities Recommended by E.Hugot

| Triple in m/sec | Quadruple in m/sec | Quintuple in m/sec | ||||

| Min | Max | Min | Max | Min | Max | |

| Exhaust steam to 1st effect | 25 | 30 | 25 | 30 | 25 | 30 |

| Vapour from 1st effect | 30 | 35 | 30 | 35 | 30 | 35 |

| Vapour from 2nd effect | 40 | 45 | 35 | 40 | 30 | 35 |

| Vapour from 3rd effect | 50 | 60 | 40 | 45 | 35 | 40 |

| Vapour from 4th effect | 50 | 60 | 40 | 45 | ||

| Vapour from 5th effect | 50 | 60 | ||||

Calendria dia at the entry of the steam/vapour jocket

- Area for the inlet vapour ( If more than one connection to calendria than take each inlet vapour area) = π/4 * (Dia of the vapour inlet)2

- Height of the steam entry = Take Effective Length of the tube.

- Width of the steam entry = Area for the inlet vapour / Height of the steam entry.

- Dia of calendria at the point of radial steam entry = Final Dia of the tube plate + Width of the steam entry.

- (Note : This dia to be maintained at the vapour entry side later it may reduced in vapour travel direction.).

4. Vapour outlet pipe dia :

- Vapour volume outlet vapour in M3/sec = Heating surface X Evap. Rate x Specific volume of outlet vapour/3600.

- Vapour outlet pipe dia in mtrs = SQRT [vapour volume /(0.785 x velocity of vapour)]

5. Dia of the condensate line :

- Number of condensate withdrawal points = Consider minimum two numbers of withdrawal points and it can be increase according to the diameter of the body.

- Volume of the condensate in M3/sec = [Heating surface X Evap. Rate ] / [ Density of water x 3600].

- Dia of the each condensate line = SQRT (Volume of the condensate each./(0.785 x velocity of condensate)).

6. Noxious gases connections :

- Generally 10 m2 heating surface area required 1cm2 area for removal of noncondensable gases.

- Cross section area of non condensable gases in cm2 = Heating surface in m2 /10

- Dia of the each non condensable gases line = SQRT( Total area of non condensable gases /0.785*no. of points)

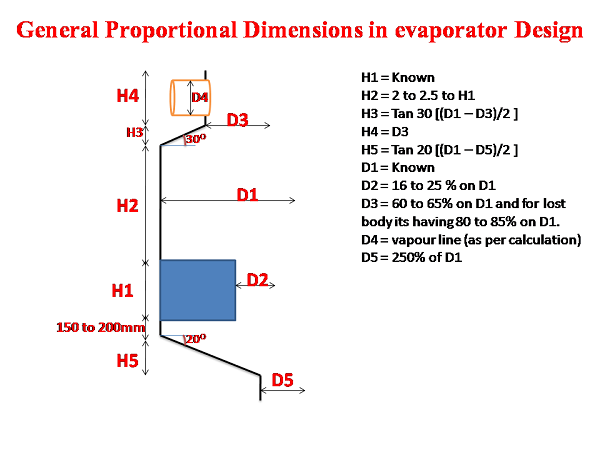

7. Vapour space height :

- Generally for Robert type bodies will take for lost effect 2.5 times on calendria tube height and for remaining bodies will take 2 times on Calendria tube height.

- Tromp quotes an American view that the height of the cylindrical body, above the calandria, should be 1.5 times to twice the length of the tubes. It is wise to specify at least twice; moreover, Tromp later recommended 2 In Europe, a minimum of 3.6 – 4.0m is adopted.

8. Velocity in vapour space of body (Cross checking of the system ):

- Generally in evaporator design vapour space dia may be take same as to calendria dia meter. But we have to check, how much vapour velocity maintained in body. It is helpful to avoid the entertainment of the system. The velocity of vapour leaving the liquid surface would then be approximately 10 cm/sec.

- In present designs, The vapour velocities in the vessels to be maintained below 3.6m/sec and for lost body it can go upto 4.6 m/sec . Hence the necessity of providing entrainment separators or save all at the vapour outlets from the evaporator vessels.

- In any case, it is considered that entrainment rapidly becomes excessive from the moment when the vapour velocity in the vessel reaches more than 6m/sec.

9. Calendria shell thickness :

- P = Maximum allowable pressure in kg/cm2

- Di = ID of the Calendria in mm

- F = Allowable stress in kg/cm2

- J = Welding Joint efficiency in mm

- C= corrosion allowance in mm

- Calendria shell thickness in mm = (P* Di / (2*F*J – P) ) + C

10. Vapour shell thickness :

- P = Maximum allowable pressure in kg/cm2

- F = Allowable stress in kg/cm2

- J = Welding Joint efficiency in mm

- C= corrosion allowance in mm

- Di = ID of the Calendria in mm

- Vapour shell thickness = (P* Di / (2*F*J – P) ) + C

11. Tube plate thickness :

- C= corrosion allowance in mm

- F = Allowable stress in kg/cm2

- P = Maximum allowable pressure in kg/cm2

- Es = Modulus factor for MS sheet in kg/cm2

- Et = Modulus factor for SS sheet in kg/cm2

- G = ID of the shell inmm

- ts = Thickness of the shell in mm

- tt = Thickness of tube in mm

- do= OD of the tube in mm

- Do = OD of the calendria sheet in mm

- Nt = Number of tubes

- K =( Es x ts x (Do -ts)) /(Nt x Et x tt x(do -tt))

- f = SQRT ( K / (2 + 3K))

- Tube plate thickness in mm = f x G x SQRT((0.25 x P)/F) + C

Generally shell thickness will be taken as follows as (in mm).

[supsystic-tables id=3]

12. Vapour doom dia :

- Generally for Robert type bodies vapour doom dia taken 2 to 2.5 times for vapour outlet pipe area.

- Cross sectional area of the vapour doom = 2 x vapour outlet pipe area.

- Vapour doom dia = SQRT (area of the vapour doom x 4/π ).

13. Top cone Height :

- Top cone angle (φ) = generally take 30 to 35 deg.

- Top cone height = Tan φ( (ID of body – ID of doom)/2)

14. Center Umbrella area :

- In Center Umbrella area calculation follows two types of methods. They are

- Area of Umbrella = Cross sectional Area of the body – cross sectional area of the doom

- Area of Umbrella = consider 60 to 65% on body dia

- Gap between Umbrella to top cone at the place of vapour inlet ( Hi ) = Area of vapour doom / π * Dia of Umbrella

- Gap between Umbrella to top cone at the place of vapour outlet ( Ho ) = Area of vapour doom / π * ID of the vapour doom*

Online Calculation Sheet for Robert Evaporator Body Design

( Note :In this calculator provided with two types of sheets. First sheet provided with formulas for better understanding and another one having simple calculation sheet)

Related Articles:

Flash Vapour Calculation | Flash Vapour Recovery Vessel Design Calculation.

Condensate Receiving Tank Design Calculation | Condensate Mound. – www.sugarprocesstech.com/condensate-receiving-tank/.

Heat Transfer Coefficient of Liquid -Liquid Tubular Heater Calculation| HTC

Raw juice temperature raised upto 70 to 75oC is the 1st step in Sugar processing.

Wetting rate concepts and formulas for evaporators calculations

Hi friends Thanks for reading and using our online calculator. I Hope you liked it. Give feed back, comments and please don’t forget to share it

29 thoughts on “Evaporator Design formulas and important design considerations with online calculator”

Awanish kumar

(May 3, 2017 - 1:21 pm)How you convert massecuite volume per cycle (m3) to kg/hr .

It is not coming now.

deepak gapat

(May 7, 2017 - 8:29 am)Here I would like to express, it is very useful information for those who work with it.

Thanking you

siva alluri

(May 9, 2017 - 2:14 pm)Thank you very much deepak sir

• The “www.sugarprocesstech.com” invites to all sugar technologists to share your knowledge, achievements in your working organization and new developments and technologies in sugar industry and its concerned units. It is very much helpful to show his identity to the world at the same time it will helpful to another technologist to enhance their insight and enhance great execution in there working. This website also provides the basic knowledge in sugar industry technologies and equipment design calculation with online calculators. http://www.sugarprocesstech.com/

Ravi Prasad Vundavalli

(May 22, 2017 - 5:23 am)thank u siva alluri for ur valuable upload

siva alluri

(May 24, 2017 - 1:32 am)Thank you Mr.ravi prasad

The “www.sugarprocesstech.com” invites to all sugar technologists to share your knowledge, achievements in your working organization and new developments and technologies in sugar industry and its concerned units. It is very much helpful to show your identity to the world at the same time it will helpful to another technologist to enhance their insight and enhance great execution in there working.

contact mail id sugarprocesstech@gmail.com

Bharatkumar Magdum

(June 13, 2017 - 7:19 am)Thank-you sugarprocesstech.It is very useful information & calculation for your valuable upload

shweta Yadav

(September 5, 2017 - 11:17 am)Sugar industries using formula to calculate heat transfer coefficient of a evaporator is= ( Evaporation coefficient x Latent heat of steam or vapour)/ Temperature difference. I am not sure about this calculation. According to chemical engineering Overall Heat transfer coefficient is a function of flow geometry, fluid properties and material composition of evaporator. Heat transfer taken place by conduction , convection and radiation.

I want to know that you have done any calculation by considering above mentioned factors to calculate Overall heat transfer coefficient of a evaporator.

siva alluri

(September 5, 2017 - 2:17 pm)According to chemical engineering formula as your mentioned process is absolutely correct sir.

But in sugar industry generally following the above mentioned formula for simplification of the calculation.

Please refer “HANDBOOK OF CANE SUGAR ENGINEERING” By E. HUGOT.

Ranjit kawade

(January 26, 2018 - 7:32 pm)Thank you so much Sir

Very Useful Data in Sugar industry.

Nice sugarprocesstech.

siva alluri

(January 27, 2018 - 5:18 pm)Thank you Mr.Ranjit

The “www.sugarprocesstech.com” invites to all sugar technologists to share your knowledge, achievements in your working organization and new developments and technologies in sugar industry and its concerned units. It is very much helpful to show your identity to the world at the same time it will helpful to another technologist to enhance their insight and enhance great execution in there working.

sugarprocesstech@gmail.com

Rohit

(March 22, 2018 - 10:44 am)Sir,

How to calculate pressure drop & steam%cane of Quantriple set ( F++F+F+R+R)

siva alluri

(March 23, 2018 - 5:04 pm)Dear Kumar,

Please go through the below links then you will get solution

https://www.sugarprocesstech.com/pressure-drop-calculation/

https://www.sugarprocesstech.com/steam-cane-quintuple/

This web site having search bar at top

You can type keywords of your requirement

Like pressure-drop-calculation, steam% cane…. Etc

Salman

(April 28, 2018 - 6:38 pm)Dear Sir,

can you please send me the References of this nice Infos,

your Sincerely

Salman

siva alluri

(May 3, 2018 - 2:41 pm)Please go through the below link for info

https://www.sugarprocesstech.com/sugar-tech/

Mo. Hashim khan

(March 2, 2022 - 4:03 pm)Sir how we calculate chemical quality for chemical boiling in the Evaporator body..

For removing scale.

Yogesh mishra

(June 20, 2018 - 7:05 am)Sir how to design tubular FFE

siva alluri

(June 21, 2018 - 2:00 pm)We will provide FFE calculation soon

Acmefil

(July 5, 2018 - 3:38 am)thanks for sharing information

Muhammad ud din

(December 8, 2018 - 6:29 am)What is optimum liquid level in tubes of evaporator?

siva alluri

(December 10, 2018 - 4:37 pm)Generally for Robert type bodies – 1/3rd level of the tube

for SK bodies – 20% of the tube length

Muhammad ud din

(November 13, 2019 - 4:37 am)We manufacture rising film evaporator for caustic soda. What should be the liquid level in tubes. ? First stage carryover frequently. We use 2.5 meter long tubes.

Kumar s p

(August 30, 2020 - 1:46 am)Which bases tube cleaning chemicals used in 1) FFE BODIES : sulphamic acid , inhibitor

2) Evaporator bodies: caustic soda, washing soda

Common salt

3)Pan : HCL and inhibitor used

Ameer Salah

(February 21, 2021 - 4:22 pm)How can I turn a black solution into steam

Ravi Kalall

(April 10, 2022 - 8:30 am)Sir

Please share Semi Kestner body drawing.

Kamlesh Kumar Soni

(June 25, 2022 - 12:49 pm)I am an engineer in sugar industry and this calculation is very useful for me thanks to all sugar technologists .

siva alluri

(June 26, 2022 - 2:21 pm)Welcome

Vamsi. V

(September 1, 2022 - 4:56 am)Can send the brief evaporator design calculations

Vamsi .V

(September 1, 2022 - 5:01 am)Actually my application is for EV in automobile can you share the details of the evaporator design calculations

Ved

(May 1, 2024 - 11:06 am)Under FFE designing what is the vapour velocity in vapour space