This article aims to provide a basic informative guide to calculating the equipment capacities for essential components in the sugar refinery, such as the raw sugar melter, melt clarification system, deep bed filters, ion exchange resin system, pan section, centrifugal section, sugar drying and grading. The major unit operations in Sugar Refinery are as follows […]

Tag: sugar refinery

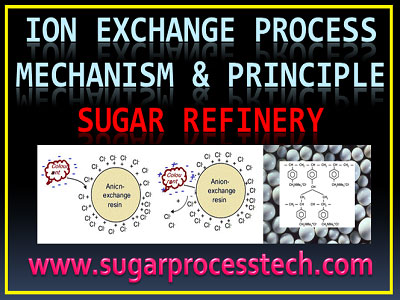

Ion Exchange Resin Process In Sugar Refinery | Basic Concepts of IER Process

The Ion Exchange Resin process (IER) are usually considered as similar to electrolytes. The IER were developed in the middle 1940’s and it is based on the co-polymerization of styrene cross-linked with divinylbenzene. Basic Concepts of Ion Exchange Resin Process for Sugar Refinery Basic Ion Exchange Process The IER system involves one ion for another, […]

Affination Process in Sugar Refinery with Material balance Calculation

In this article discussed about factors involved in affination process of standalone refinery with material balance calculation. Material Balance of Affination Process in Sugar Refinery What is Affination Process Affination process is a first step in the sugar refinery process when high colored raw sugar taken as a input material. This process can be defined […]

Color, Solids and Purity Balance of Refined Sugar Massecuite Boiling

This article is given a general idea about color, Solid and purity balance and intermediate product colors in Refined Sugar Massecuite Boiling. Intermediate Products Color, Solids and Purity of Crystallization in Sugar Refinery Process Pan Boiling/Crystallization Scheme of refined sugar a) This fine liquor obtained from second decolurization process is evaporate in falling film evaporator […]

Melt Clarification System Design Criteria for Sugar Refinery Process

Syrup Clarification Design for Plantation white sugar manufacturing In this article explained about the design criteria of syrup and melt clarification system required equipment capacity like buffer tank, melt heater, reaction vessel, aeration vessel, chemical holding and dosing tanks, dosing pumps capacity, pipe lines and flotation clarifier. Also provided online calculator for Syrup and melt […]