Fundamental Concepts of Overall Heat Transfer Coefficient (OHTC)

In shell and tube type heat exchanges overall heat transfer coefficient (OHTC ) is product of the three factors mainly. They are Tube inside liquid media film coefficient , Shell side heating media film coefficient and metal wall resistance.

Heat transfer is the science which deals with the rates of exchanges of heat between hot and cold bodies called source and receiver.

There are three distinct ways in which heat may pass from a source to receiver. Although the most engineering applications are combination of two or three.

These are conduction; convection and radiation are the basic mechanism for the heat transfer.

Conduction

When heat flows through a body by the transference of the momentum of individual atoms or molecules without mixing it is said to be flow of conduction.

I.e Conduction is the transfer heat through fixed material such as the stationary wall.

Convection

When heat flows by actual mixing of warms positions with cools positions of same material the mechanism is known as convection

i.e Heat transfer by convection occurs in a fluid with another position due to gross movements of the mass fluid.

Convection can be further sub divided into free convection and forced convection.

If the fluid is made to flow by an external agent such as a fan or pump, the process is called forced convection. If the fluid is caused by density’s differences which creates by the temperature differences existing in the fluid mass, the process is termed free convection or natural convection

It is very rarely that flow through fluids by pure conduction without some convection. The actual process of energy transfer from one fluid particle or molecule to another is still one of the conduction, but the energy may transfer ported from one point in space to another by the displacement of the fluid it self.

Radiation as a term given to transfer of energy through space by means of electromagnetic waves.

According to conduction

Let Area of wall “A“ thickness of wall “Th”

Fouries law states that the rate of heat flow through a uniform material is proportional to the area, the temperature and inversionaly proportional to the length of the path of flow

Km = Thermal conductivity of material

Q = Rate of heat flow

ΔT = Driving force

(Th /Km x A ) = Resistance

For easy understanding of overall heat transfer coefficient (OHTC) take a simple case.

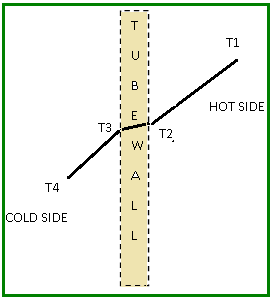

Consider a heat flow by conduction and convection by pipe wall with forced convection of different magnitudes on both sides of the pipe as shown below figure. On the outside, heat is deposited by hot flowing liquid, and on the inside heat is received by a cold flowing liquid.

Either resistance can be measured independently by obtained the temperature difference between the pipe surface and the average temperature of the liquid. The heat transfer can be determined from the sensible heat change in either fluid over the length of the pipe in which the heat transfer occurs.

The hot side liquid temperature T1, cold side liquid temperature T4, and the temperatures of hot and cold sides pipe wall T2, T3 respectively.

Designating the resistance the pipe inside by Ri and on the outside by Ro ,

Because of the complicated structure of turbulent flowing Stream and the impracticability of measuring thickness of the several layers and their temperatures are not considered.

Suppose take that Q Kcal/ hr are flowing from hot fluid to the cold fluid.

Then Q Kcal/hr passes from the hot fluid to metal and same pass in metal and then metal to cold fluid.

And average area of metal wall “A” Now applying an expression for the steady state,

Replace the resistances by their reciprocals “ho” and “hi” respectively

Q = A ho (T1 – T2 ) = A hi (T3 – T4)

The reciprocals of the heat transfer resistances have the dimensions of the Kcal / hr/m2/ oC or Kw/m2/ oC and are called individual film coefficients or surface coefficients.

hi = Tube Inside material film coefficient.

ho = Tube outside material film coefficient.

The above equation can be written as

In above consideration case as consisting of three resistance in series.

First the resistance on the side of hot fluid (1/A ho).

Second the resistance of the metal wall Th/KmA , and

Third, the resistance on the side of the cold fluid 1/A hi.

The overall resistance is equal to the sum of the individual resistance, just as is the case in the flow of electric current through a series of resistance.

Now heat flow from hot fluid to cold fluid

Here U = overall heat transfer coefficient in kcal/ hr / m2/oC or Kw/m2/ oC

I.e the above equation states that the overall heat transfer coefficient (OHTC) is product of the three factors. But in typical OHTC calculation along the three factors also consider the resistances due scaling on both sides of tube. (dirt coefficient or fouling factor).

ΔTm = LMTD in oC .

So to find appropriate temperature difference between hot and cold material use the logarithmic mean temperature difference (LMTD).

Some Related Articles

Sugar Tech | Sugar Technology related articles with online calculators

Condensate Receiving Tank Design Calculation | Condensate Mound | Condensate Receiving & Condensate Flash Recovery tank design

Heat Transfer Coefficient of Liquid -Liquid Tubular Heater Calculation| HTC | How to find Condensate Juice Heater Heat Transfer Coefficient Calculation.

Flash Vapour Calculation | Flash Vapour Recovery Vessel Design Calculation. Condensate flash vapour recovery system calculation with example.

Hi friends Thanks for reading the material balance calculation. I Hope you liked it. Give feed back, comments and please share it.

6 thoughts on “Overall heat transfer coefficient for shell and tube heat exchanger”

Harness Yadav

(October 11, 2018 - 6:27 am)Dear sir

This site is very beneficial for the sugar field technocrats to improve their technical skills. I would like to request you to include latest technical research and information for your site reader like us.

Thanking you

siva alluri

(October 12, 2018 - 4:08 pm)Thank you Mr.Harness Yadav

Abdo

(November 5, 2019 - 12:03 pm)How to calculate “hi” and “ho” heat transfer coefficients for boiling inside and condensation outside???

siva alluri

(November 5, 2019 - 4:57 pm)Please go through the below link

https://www.sugarprocesstech.com/heat-transfer-coefficient/

Shreeshail

(September 18, 2020 - 10:36 am)how to find evaporater each body heat transfer coefficent sir please solve

siva alluri

(September 18, 2020 - 1:00 pm)For calculation HTC in evaporator bodies having different formulas.

In that Dessin formula is one of popular formula to find the HTC in evaporator bodies.

Dessin proposed a formula permitting the evaporation coefficient to be calculated for any vessel of a multiple effect:

C = 0.001 (100 – B) (T – 54)

C = specific evaporation coefficient for the evaporator, in kg of vapour/ m2/oC/hr

B = Brix of the juice leaving the vessel

T = temperature of the heating steam in the calendria, in °C (°F).

(Note: To get better result from the above formula to be take in the place of coefficient 0.001 as follow as

For 1st effect = 0.001,

2nd effect = 0.0009,

3rd effect= 0.0009,

4th effect = 0.0008,

5th effect = 0.0008).

Here we obtained Evaporation coefficient

We multiplying the vapour latent heat for that particular body in Kcal/kg with Evaporation coefficient to Calculation the Overall heat transfer coefficient in Kcal/m2/0C/Hr

Please go through the below link

https://www.sugarprocesstech.com/steam-cane-quintuple/