Bagacillo Screens, blower & Bagacillo Cyclone Sizing Calculation

In this article briefly discussed about bagacillo requirement for vacuum filters. Bagacillo screen, Bagacillo blower capacity requirement, Bagacillo transport line sizing and Bagacillo cyclone design calculation.

Role of bagacillo in mud treatment process of vacuum filters:

A fine fraction of bagasse termed bagacillo. It is used as a filter aid in the rotary vacuum filter station. Bagacillo helps to form mud in porous layer on the rotary vacuum filter drum. Due to porous nature we can easily extract the sucrose from the filter cake by wash water. Bagacillo must be very fine, smaller than 0.85 mm in diameter. The surface area of the filter aid is most important because the smaller in size greater will cover the area per kg of bagacillo. A common criterion for the bagacillo should be pass through 20 mesh screen by least 85 % of the material and 4 mesh screen by least 80-90 % of the material.

Bagacillo quantity required 6 to 8 kg per tonne of cane. While consider the wet filter cake then 6 to 10% of bagacillo required on weight of filter cake.

Bagacillo screens

Generally bagacillo screens are perforated plate with holes of 5 to 10 mm diameter. For Best results have been achieved with the 5mm hole dia screens or 4mesh. The quantity of bagacillo obtained from screens varies according to the cane preparation. (Preparatory Index of the milling section). The quantity of the bagacillo will furnishes 60 to 135 kgs of bagacillo/m2/hr.

Bagacillo Blower and its pipe line :

Bagacillo extraction from final bagasse and its transport from the bagacillo collection chamber to mud mixer is very important for filter operation. The quantity of bagacillo conveyed by the air with the help of fan. The quantity of bagacillo produced can be controlled by regulating the amount of air admitted through the bleed line damper. As this is opened, less air is sucked through the separator and the quantity of bagacillo reduces.

Air required for bagacillo Pneumatic transport is 6 to 6.5 M3 of air will be required per kg of bagacillo. The velocity of air in duct line generally considered 2 to 3m/sec. And the velocity consider for bagacillo transport pipe line sizing is 15 to 20 m/sec. The MOC of the pipe line used GI or PVC.

Bagacillo Cyclone :

The purpose of the bagacillo cyclone is separating bagacillo or pith from an air stream. The Particles having more than 5 µm can usually be separated from a gas stream. In general a smaller diameter cyclone gives a higher pressure drop and a higher collection efficiency.

The pressure drops throughout the cyclone owing to several factors:

- Gas expansion.

- Vortex formation.

- Friction loss.

- Changes in kinetic energy.

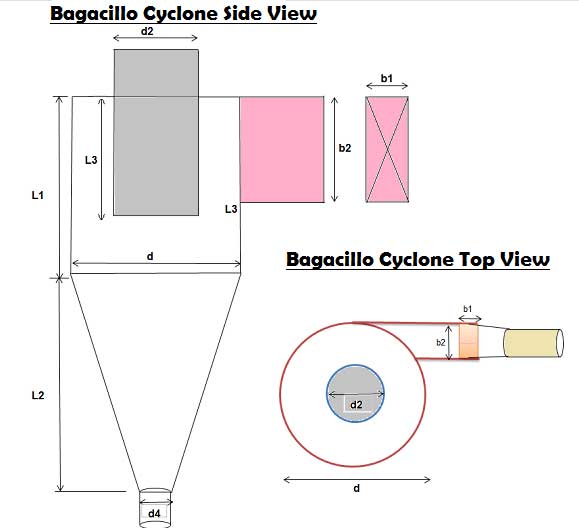

Here given simple design for bagacillo cyclone design calculation. ( This geometry recommend by Perry and Green )

The dia meter of the cyclone : Q = 1.9 d2.

where Q is volumetric flow expressed in M3/sec & the ” d ” cyclone diameter in mtrs.

Provide the tangential rectangular entry for the inlet line of cyclone separator. The tangential entry length (b2) and width(b1) required d/2 & d/4 respectively.

The cylindrical height of the cyclone L1 = 2d and reducer length (L2) also to be take 2d. So total length of the bagacillo cyclone is 4d (Except air vent line).

The bottom dia (d4) of the cyclone is d/4.

The air vent line dia (d2) is to be consider d/2.

The inserted length (L3) of air vent into the cyclone is to be consider 5d/8.

Take one example for better understanding purpose.

Take 230TCH plant, Calculate bagacillo screen, bagacillo blower and its pipe line capacity requirement and also find the suitable size of bagacillo cyclone.

Bagacillo screen, blower, pipe line, cyclone calculation |

||||

| S.No | Description | Values | UOM | Remarks |

| Required Data | ||||

| 1 | Plant Capacity | 230 | TCH | TCH |

| 2 | Bagacillo requirement | 7 | Kg/TCH | Ba |

| 3 | Bagacillo obtained from screen | 60 | kg/m2/hr. | Bs |

| 4 | Air requirement for transportation of Bagacillo | 6.5 | M3/ kg of bag. | Bt |

| 5 | Velocity in air duct line | 3 | m/sec | Vo |

| 6 | Velocity in Bagacillo transport line | 20 | m/sec | V |

| 7 | Bagacillo density | 120 | kg/m3 | ρ |

| Calculation Part | ||||

| 1 | Bagacillo requirement | 1610 | Kg/ hr | TCH x Ba |

| 13.417 | M3/hr | TCH x Ba/ ρ | ||

| 0.0037 | M3/sec | |||

| 2 | Bagacillo screen required | 26.8 | m2 | TCH x Ba / Bs |

| 3 | Bagacillo blower capacity | 10465 | M3/hr | TCH x Ba x Bt |

| 2.9069 | M3/sec | Qa | ||

| 4 | Air duct line size for blower | 0.969 | m2 | Qa/Vo |

| 1.111 | mtr | |||

| 5 | Air + Bagacillo Quantity | 2.9107 | M3/sec | Q |

| 6 | Bagacillo transport line size | 0.1455 | m2 | A = Q / V |

| 430.57 | mm | |||

| 7 | Bagacillo cyclone Dia | 1.2377 | mtr | d = sqrt( Q/1.9) |

| To be take | 1200 | mm | ||

| 8 | Tangential rectangular entry length | 600 | mm | b2 = d/2 |

| 9 | Tangential rectangular entry width | 300 | mm | b1 = d/4 |

| 10 | Cylindrical height of the cyclone | 2400 | mm | L1 = 2d |

| 11 | Reducer Length of the cyclone | 2400 | mm | L2 = 2d |

| 12 | Bottom dia of the cyclone | 300 | mm | d4 = d/4 |

| 13 | Air vent line dia | 600 | mm | d2 = d/2 |

| 14 | Inserted length of air vent into the cyclone | 750 | mm | L3 = 5d/8 |

Related Topics

Vacuum Filter Description in sugar industry | Optimization of Sugar Loss

Rotary vacuum filter Equipment capacity details in sugar industry | Rotary Vacuum Filter Accessories Capacity Calculation |Sugar Tech

Sugar Industry Equipment Design and Drawing Online Calculations.

Hi friends Thanks for reading the material balance calculation. I Hope you liked it. Give feed back, comments and please share it.

16 thoughts on “Role of Bagacillo in vacuum filter | bagacillo cyclone Capacity Calculation”

salahuddin

(November 23, 2017 - 7:45 pm)Wonderful and informative article about bagacillo requirement and sizing of related equipment. Thank you sir

siva alluri

(November 24, 2017 - 4:37 am)Thank you

The “www.sugarprocesstech.com” invites to all sugar technologists to share your knowledge, achievements in your working organization and new developments and technologies in sugar industry and its concerned units. It is very much helpful to show your identity to the world at the same time it will helpful to another technologist to enhance their insight and enhance great execution in there working. This website also provides the basic knowledge in sugar industry technologies and equipment design calculation with online calculators.

sugarprocesstech@gmail.com

Prem Kumar.S

(December 21, 2017 - 6:28 pm)Very useful siva

siva alluri

(December 23, 2017 - 1:10 pm)Thank you

omveer singh

(February 20, 2018 - 1:54 am)I think step towards digitization and open to all your sharing knowledge is really mind game.

Hope to add those who wants to share topics related to sugar enginnering/core engineering.

Thanks,

SANTOSH

(February 28, 2018 - 3:44 am)Very useful

B. N Amarendra

(April 1, 2018 - 1:42 pm)Hello sir,

Pl, tell us the C-masscuite reheater design calcuation.

siva alluri

(April 2, 2018 - 4:38 am)we will provide soon

Umesh I Nalawade

(May 21, 2018 - 10:24 am)Sugartechprocess is very usefull for theoretical and calculation part.

Sir.

Please tell us how to calculate the heat loss

siva alluri

(May 21, 2018 - 1:48 pm)Thank you Mr. Umesh

I can’t understand your requirement

“how to calculate the heat loss”

i.e in which area you wont to calculate heat loss

Ghulam Hyder Rind

(September 19, 2018 - 5:02 am)Its so informative , Thanks a lot please , some thing about house material balancing in order to rule of thumbs kindly be working on it.

siva alluri

(September 20, 2018 - 4:25 pm)Thank you Mr.Ghulam Hyder Rind

Ok we will think about same and published soon

Abeid Salum

(March 7, 2019 - 8:28 pm)Good informative article,thanks for sharing. It’s good to share our experiences in sugar industry

siva alluri

(March 8, 2019 - 3:43 pm)Thank you

Ajay pratap mal

(May 23, 2022 - 7:11 am)Sir ,pl tell us how to calculate bagacillo screen size..For 12000 tcd plant

siva alluri

(May 31, 2022 - 4:15 am)Please go through the below link

https://www.sugarprocesstech.com/bagacillo-cyclone-design/