Condenser System for vacuum creations and its types with design criteria

Condenser system and vacuum equipment are common to evaporators and vacuum pans. Nearly all these vessels use direct contact condensers, where the cooling water comes into direct contact with the vapour to be condensed.

Creation of Vacuum:

a) In a condenser, we condense large volume of vapour and it will only produce a comparatively small volume of water or (condensate) and this water runs out through the bottom of the condenser down the barometric leg with the waste water.

b) Therefore if we have condensed the large volume of vapor into small volume of water in a condenser, the remaining volume or area must be a vacuum(reduced). Thus we have created a vacuum.

c) With the aid of an air pump or other, vacuum is produced in an enclosed vessel called a condenser, which communicates with the vessels to be maintained under vacuum.

d) Cold water is pumped in to the condenser to ensure condensation of vapour coming from pan or multiple effect evaporator. The Condenser is placed at a height that the water after condensation flow out by gravity together with condensed vapours. The Condenser is a barometric chamber extended at bottom by a barometric column dipping into a well open to atmosphere.

The Barometric Column :

There are two dimensions of importance in the barometric column

Height of the barometric column

Cross-section of the column

Height of the barometric column :

The height of the column represents the sum of 3 terms:

Ho = head of water corresponding to the maximum vacuum in the condenser

h = head necessary to give the desired downward velocity of the water

s = margin of safety as provision for abrupt variations in level of the water in the column.

H = Ho + h + s

Ho is the minimum head of water required to have maximum vacuum in condenser. The height of the column should be of the order of 10 (instead of 76 cm): (Vacuum in mtr of Hg x Density of mercury/ Condenser inlet water density)

0.76 m X 13.6 = 10.33 m where 13.6 = density of mercury relative to water.

h =The head necessary to give desired velocity of water

h= (1 + a) ( V2 / 2g)

h = head of water, in mtr necessary to maintain flow in the column, at velocity V

V = velocity of flow in the column, in m/sec

g = 9.8 m/sec2

a = coefficient,

The values of coefficient given by Hausbrand as follows

| Column |

Diameter of the column in mm |

||||

| 50mm | 100mm | 200mm | 400mm | 800mm | |

| Straight | 6.1 | 2.6 | 1.2 | 0.6 | 0.4 |

| With Double 90o bends at base | 6.7 | 3.2 | 1.8 | 1.2 | 1 |

S is the Safety margin for sudden variations in vacuum or flow in water. It may take in general 0.50 mtr.

Cross-section of the column:

The cross-section of the barometric column requires simply to have sufficient cross-section to assure discharge of the water.

D =

D = diameter of the column, in mtr

V = velocity of flow of water in the column, in m/sec

Q = weight of vapour to be condensed, in M3/sec

W = ratio of weight of injection water to weight of vapour condensed,

According to Peter rein More simply, following the form of equation

D > 1.116 x (Qw )0.4

Qw = Total Water and vapour flow rate in condenser in M3/sec.

The velocity of water in the barometric column is maintained at 2 to 3 mtr /sec. So that the air bubbles do not escape and rise in condenser. They should pass along with water through tail pipe. For single entry type condensers it may take upto 4 to 5 mtr/sec.

Types of Condenser System :

From the extraction of the air point of view the condensers can classified as

Wet air condensers : Condenser with combined vapour and air extraction.

Dry air condensers : Condenser with separate arrangement for air extraction.

In Sugar Industry generally used the following types of condensers

a) Barometric condenser

b) Multi-jet condenser

c) Single Entry Condenser

Barometric condenser

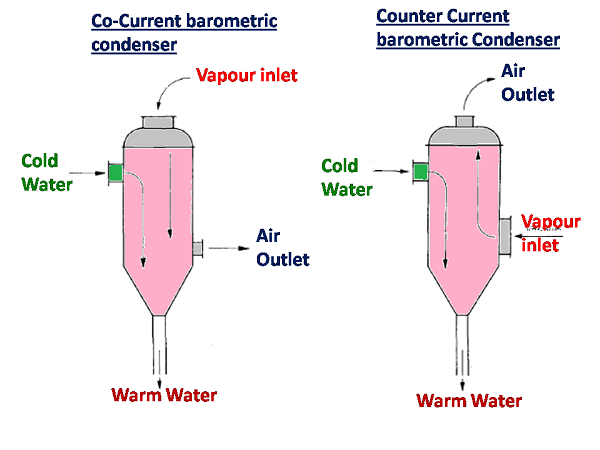

a) In Barometric condensers having two types. They are Co-Current barometric condenser and Counter Current barometric condenser.

b) Co-Current, barometric condenser water and vapour are introduced to the condenser from top and the worm water is let out removed from the bottom.

c) Counter Current barometric condenser. water and vapor are introduced in opposite direction. Baffles with perforation are provided to ensure more contact time and surface between water and vapour

d) Compared to the co-current type, counter current type barometric condenser works more efficiently.

Height of the condenser:

Height of the condenser:

The condenser is a device for exchange of heat between vapour and cold water. The exchange will be the more complete as contact between these two fluids is more intimate.

Height of Condenser is decided as per the time that is necessary for the water to remain in contact with steam. While proper arrangement of baffles in condenser to increase the contact area than the overall height of 3.65 mt ( 12 ft) is sufficient .

Cross-section of the condenser.

The cross-section will depend directly on the quantity of vapour to be condensed.

S = 0.16 m2 / ton of vapour to be condensed per hour. where S = horizontal cross-section of the body of the condenser.

Condenser volume :

The condenser volume of 0.75 m3/ 1000 kg of vapour is recommended however 0.5 m3/ 1000 kg vapours can be considered as a reasonable figure for rain type condenser. however, has determined experimentally that 0.6 m3/ 1000kg per hour was sufficient in most cases. In some designs provide maximum effective contact area of water to vapour in that design it will take 0.4 to 0.3 m3/ 1000kg per hour.

Also can be cross checking by Volume of condenser = Cross sectional area x Height of the condenser

The cone at the bottom of the barrel should have a slope of 70° to the horizontal.

Diameter of cooling water pipe :

The cooling water may be supplied by a pump. Its effective head, h, will be equal to the geometrical head at the entry to the condenser, increased by the vacuum in head of water. We have then:

V = a x

V = water velocity in the inlet pipe, in m/sec

a = coefficient depending on the length of the pipe, its bends, valves and other obstructions to flow. In general, ” a ” is of the order of 5

g = 9.8 m/sec2

h = head of cold water, at entry to condenser, in mtr (h = pressure Of water at inlet X head at mean sea level)

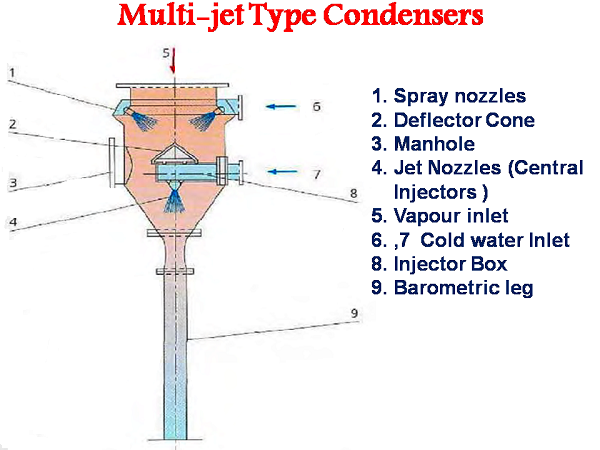

Multi Jet Condensers ( Wet air barometric condensers) :

Principle :

Jet condensers were first placed on the market by Schutte – Koerting about 1930. They are based on the dynamic effect of jets of water which, penetrating into the body of water in the barometric column, enter with them, by friction, the air contained in the condenser. If the cross-section of the barometric column is small enough to ensure a suitable velocity, the bubbles of air do not rise into the condenser and are evacuated to the well at the foot of the column.

a) The main difference with the Multi Jet condenser is that, it does not require air pump, and although it requires more water than the dry air type condenser, it is more economical to operate and maintain.

b) This type of condenser has high pressure water jet nozzles fitted in the lower section of the condenser, directed straight at the outlet or barometric leg. The vapor inlet to the condenser is from the top of the condenser much above the level of the jet.

c) The nozzles are called as jet nozzles and they create vacuum in the system. The jet is given such manner, that the jet of water will flow exactly through the center of the tailpipe. On the top portion of the jet box another set of nozzles is fitted circumferential through which the flow of pressurized water is flowing towards the center of the box. This part of water is responsible for the condensation of vapour, which is called as spray nozzles.

d) As against the dry air type, the Multi Jet differs (wet type) in principle that due to the high velocity of water passing down the barometric leg, air or gas bubbles will not rise but instead it will be drawn away through the outlet with the waste water.

e) The pressure of water in both the parts to be employed as between 0.5 to 0.7 kg/cm2 for observing the pressure the gauges are fitted to inlet pipes. The proportion of the quantity of water is in ratio of 40% water to jet and 60% to spray.

Diameter of spray nozzle (Ds)

Ds =

As (area of the each spray nozzle ) = Qs / Vs

Qs = Quantity of water per each spray nozzle in M3/Sec = Quantity of water / No. of spray nozzles

Vs = Velocity of water at nozzle in m/sec =

h = Pressure of water at spray nozzle in kg/cm2 x head at mean sea level

Diameter of jet nozzle (Dj ):

Dj =

Aj (area of the each jet nozzle) = Qj / Vj

Qj = Quantity of water per each jet nozzle in M3/Sec = Quantity of water / No. of jet nozzles

Vj = Velocity of water at nozzle in m/sec =

h = Pressure of water at jet nozzle in kg/cm2 x head at mean sea level

Condenser Vapour pipe dia :

Quantity of vapour to condensed (Q) = Heating surface of the equipment x Evaporation rate.

Cross sectional area of the vapour pipe = Quantity of vapour in M3/sec / Velocity of vapour in m/sec.

Condenser Diameter :

Cross sectional area of the condenser =( Quantity of vapour in M3/sec + Quantity of inlet water to the condenser in M3/sec) / Velocity of vapour in m/sec.

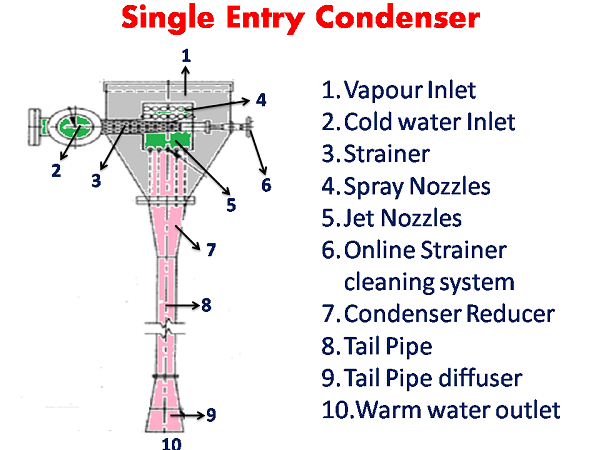

Single Entry Condenser:

a) Single entry condensers are having only one water distributing box for spray and jet nozzles. Out of total water about 60 to 80 % water is used at Spray nozzles and 20 to 40 % water for jet nozzles.

b) Vapours are condensed by forming fine mist inside the condenser, increasing surface area of contact and finally minimum requirement of water.

c) The difference between approach temperature ( difference between vapour temp. and condenser water tail pipe temp) does not exceed 5 to 60C.

d) The Specially designed high efficiency centrifugal spray nozzles fitted on the jet box create micro fine atomized spray, resulting into wider surface contact with incoming vapours.

e) The difference between water outlet temperature and inlet temperature of 10°C is achieved. Under automation the difference can achieved upto 15°C.

f) Single entry and Multi jet condensers are of Parallel flow type wet air condenser. The Single entry condenser requires less water than conventional Multijet condenser due to the following reason.

g) In the single entry condenser design the spray nozzles are fitted in nozzle box which fitted at the center of the condenser. Thus the spray water covers all the available area inside the condenser hence the spray water particles contact area for the vapour condensation is more than the multi-jet condenser system. Another impotent parameter in this design tail pipe diameter and velocity of water in the tail pipe .

h) The nozzles dia calculation same as multijet condenser. The velocity of warm water (outlet water ) goes upto 4 to 5 m/sec. The design of bottom cone, its reducer and venture were placed important role.

Condenser Water Requirement

In a condenser the vapours entering, transfer heat to the cold injection water, the heat transmission depending on the temperature and quantity of water. Based on the heat balance the equation for arriving at the quantity of injection water is.

Cooling water ratio ( W ) i n Kg of injection water per Kg of vapour = where

I = Total heat of vapour in Kcal/kg ( For 55 oC temperature of vapour the total heat having 621 Kcal/kg)

For saturated online steam table purpose go through the link Online Steam Table for Saturated Steam

Ti = temperature of injection water in °C

To = temperature of condenser outlet water in °C.

According to E.Hugot the optimum value of this Ti and To difference is 10°C.

The difference in temperatures of vapour being condensed and the outlet water termed as approach should be minimum since the efficiency of the condenser operation depends on the fact that minimum quantity of water should absorb all the latent heat of vapour.

Under normal conditions the cooling water ratio to vapour condensed in around 50 to 60 for barometric condensers, 60 to 70 for Multi jet condensers and 40 to 50 for single entry type condensers.

In the next revision of this article will provide online calculation sheet of condenser design.

Related Articles:

Three and half massecuite boiling material balance calculation.

Solid Balance in Sugar industry process | Material Balance Calculation | Sugar Factory Material Balance Calculation for three massecuite Boiling.

Thumb Rules for Sugar factory Equipment Design Sizing

Sugar Industry Equipment Design and Drawing Online Calculations

Condensate Receiving Tank Design Calculation | Condensate Mound

Fundamental Concepts of Overall Heat Transfer Coefficient (OHTC)

Hi friends Thanks for reading. I Hope you liked it. Give feed back, comments and please don’t forget to share it

46 thoughts on “Concepts in Condenser System (Vacuum Equipment)”

premkumar tamilnadu

(June 27, 2017 - 9:46 am)i read your article about condensor system. now i need detailed data of water consumption for vapour condensing calculation.thank you

siva alluri

(June 27, 2017 - 3:05 pm)Dear Prem,

water consumption calculation also given in the above article

Condenser Water Requirement

Ritesh Gupta

(June 9, 2018 - 9:09 am)Description is very good

siva alluri

(June 13, 2018 - 5:35 pm)Thank you Mr.Ritesh Gupta

Mesfin Tibebu

(January 30, 2018 - 12:27 pm)More brief on “Concepts in Condenser System (Vacuum Equipment)”

siva alluri

(January 30, 2018 - 1:34 pm)Thank you Mr.Mesfin

chaitanya

(February 10, 2018 - 6:14 am)Why injection pumps left the water in running mode?

Alok kumar

(August 12, 2018 - 1:06 pm)Dear as u asked why water left during operation so in case of vertical pump the chance of water problem is negligible but in centrifugal type when some foreign particle may contact then some air go through impeller eye at that time pump will not lift up during operation this type problem faced some time lack of water in suction side is also a reason

Saptono sudigbyo

(March 10, 2018 - 10:02 pm)sir i want balance of water and steam from star up till steady condition in processing, please help me sir. Thank you

siva alluri

(March 12, 2018 - 3:32 pm)Ok Mr.saptono

We shortly will publish articles on steam and water balance soon.

Saptono sudigbyo

(March 13, 2018 - 4:25 am)Sir, how to count the capacity gas vacum evaporator

siva alluri

(March 13, 2018 - 2:17 pm)I can’t understand your question

Saptono sudigbyo

(March 13, 2018 - 9:44 pm)Sir, how to count capacity of vacum pump, vapour debit 31,4 ton/hour temperatur 55 degree Celcius. thank you

siva alluri

(March 14, 2018 - 3:59 am)Then cold water required for condenser = 572 * X / 0.88 (temp. of vapour – temp. of water) ( here x = vapour in T/hr)

Vacuum pump not suitable for vapor extraction.

Generally ejector used for air ejection in condenser

vijaykumar Dure

(June 27, 2018 - 8:00 am)Sir i want reasons for All are maintain Clarifier (Dorr) compartment Height 1.5mtr.

siva alluri

(July 5, 2018 - 4:51 pm)It is depended upon the settling rate and velocity of the juice inside clarifier.

3-6 m/hr gives perfect laminar flow

The speed of settling of an average juice is approximately 75 mm per minute, until the concentration of the muds near the bottom has reached a maximum.

Bases on this Clarifier (Dorr) compartment maintained Height 1.5mtr.

Alok kumar

(August 12, 2018 - 1:07 pm)Dear as u asked why water left during operation so in case of vertical pump the chance of water problem is negligible but in centrifugal type when some foreign particle may contact then some air go through impeller eye at that time pump will not lift up during operation this type problem faced some time lack of water in suction side is also a reason

Ratnesh Kushwaha

(September 6, 2018 - 4:43 pm)Dear

Sir

How to calculate condenser tail pipe hight

siva alluri

(September 6, 2018 - 5:32 pm)Dear Ratnesh Kushwaha

It is very simple

Formula : 13.6 x vacuum in meter of Hg

For example vacuum in the vessel having 500 mm of Hg then its tail pipe required is

13.6 x 0.5 = 6.8 meters

It may be take extra 0.5 to 1.0 m to withstand fluctuation

Go through the below link

https://www.sugarprocesstech.com/condenser-system/

Kripanshu Mohan Srivastava

(December 3, 2018 - 11:54 pm)Nothing is hidden

siva alluri

(December 10, 2018 - 4:38 pm)Yes nothing

Shoban Ali

(April 19, 2019 - 4:51 am)Dear Sir,

Please provide online calculation sheet for condenser design.

siva alluri

(April 19, 2019 - 11:13 am)Ok we will provide soon

Rahul

(April 29, 2019 - 10:25 am)How to calculate the number of spray nozzles and jet nozzles to be provide

DER

(July 23, 2019 - 7:38 am)Dear Sir,

I want you to explain more about this

h = Pressure of water at spray nozzle in kg/cm2 x head at mean sea level

Can you give an example?

Thanks Sir!

siva alluri

(July 31, 2019 - 4:04 pm)for example

water pressure at spray nozzle = 0.25 kg/cm2

Head at mean sea level = 0.760 m of Hg x 13.6 (Density of mercury) = 10.33 m

then h = 0.25 x 10.33 = 2.6

Please go through the below link for better understanding

https://www.sugarprocesstech.com/pressure-head-pump/

Manjunath Y

(April 11, 2021 - 8:17 am)Ple provide calculation for requirment of number of spray and jet nozzles with condenser capacity 15mt

Kiran Shelar

(September 17, 2019 - 8:41 am)Informative article…

siva alluri

(September 17, 2019 - 1:57 pm)Thank you

DER

(October 17, 2019 - 3:23 pm)Thanks Sir,

Please provide calculation formula Quantity of Vapor to condenser at any time.

siva alluri

(October 30, 2019 - 3:52 pm)Please go through the below link

https://www.sugarprocesstech.com/surface-condenser-jet-condeser/

DER

(November 5, 2019 - 8:51 am)Dear Sir,

Please explain to me

For example:

Water inlet temperature: 33 °C, Vapor temperature: 52 °C, temperature of condenser outlet water: 47 °C

So: Ratio W = (619.7-47)/(47-33) = 40.9

How to calculate quantity of vapour condensed? or quantity of cooling water requirement ?

Thanks Sir!

siva alluri

(November 5, 2019 - 5:02 pm)Quantity of vapour depends steam balance and last body evaporation rate

Please go through the below links

https://www.sugarprocesstech.com/steam-cane-quintuple/

https://www.sugarprocesstech.com/surface-condenser-jet-condeser/

Der

(November 7, 2019 - 3:56 am)Thanks Sir,

Dear Sir,

Consider condenser automation for one vacuum pan. They are give parameter vapour condensed (t/hr) (at any time). So how to calculate this parameter?

Please help to me, thanks Sir!

siva alluri

(November 7, 2019 - 7:58 am)Batch Vacuum Pan Design Calculation

https://www.sugarprocesstech.com/batch-vacuum-pan/

Der

(November 7, 2019 - 8:29 am)Thanks Sir,

Please provide online calculation sheet for condenser design and condenser automation.

siva alluri

(November 7, 2019 - 8:49 am)Ok we will provide soon

Sandeep Sahoo

(September 18, 2020 - 3:17 pm)height of clarifier compartment is 1.5mtris not cleared ,how to calculate condenser tail pipe length, design capacity calculation of vertical continuous pan .

siva alluri

(September 20, 2020 - 11:08 am)Please go through the below link

https://www.sugarprocesstech.com/condenser-system/

narendra kumar

(June 29, 2021 - 11:03 am)sir how calculate height and cross section area of multi jet condenser please

Clover Rayner

(August 3, 2021 - 1:29 pm)With the aid of an air pump or other, vacuum is produced in an enclosed vessel called a condenser, which communicates with the vessels to be maintained under vacuum.

Clover Rayner

(August 4, 2021 - 1:21 pm)Condenser system

and vacuum equipment are common to evaporators and vacuumpans. Nearly all these vessels use

direct contact condensers

, where the cooling watercomes into direct contact with the vapour to be condensed.

LESLIE BATISTA DE OLIVEIRA SOUSA

(November 17, 2021 - 8:36 pm)Please, does anyone have any literature, bibliographical reference on direct contact capacitors? Because I searched a lot about the subject on the internet and I didn’t find anything about sizing this equipment.

Thanks.

basavaraj c mutnal

(April 7, 2024 - 7:16 am)sir pressure in spray nozzel is 0.26kg/cm2, what abt pressure in jet nozzle and valocity in jet nozzel ,spray nozzel..?

siva alluri

(April 22, 2024 - 5:32 am)Required 0.4 to 0.5 kg/cm2 at jet and spray nozzle inlet

Basavaraj c mutnal

(April 7, 2024 - 8:00 am)Sir velocity in jet & spray nozzles , pressure in jet nozzles..?