Formulas for Design Direct Contact Heater (DCH) with Online calculation Sheet

Objectives of Direct Contact Heater (DCH)

a) The direct contact heaters were constructed with stainless steel body. In direct contact heaters the hot and cold streams are bought into contact without any separating wall and high rates of heat transfer are achieved.

b) The equipment basically simple and cheap and is suitable for use with heavily fouling fluids and with liquids containing solids, spray chambers, spray columns and plate and packed columns are used.

c) Most applications will involve the transfer of latent heat as well as sensible heat, and the process is one of simultaneous heat and mass transfer when the approach to thermal equilibrium is rapid, as it will be in many applications.

Important features of direct contact heater:

a) Direct contact heater is a heat exchanger where the heating and heated medium comes in contact in counter current way.

b) In conventional or dynamic Juice heaters we have to reach temperature difference between heating media and heated media (Temperature approach) ΔT in the tune of 6-100 C. In the case of direct contact Heater the ΔT could be maintain as low as 1-20C. So we achieve the final temperature of the product can be preceding vapour when compare to tubular heater .

c) Continuous operation without any need for cleaning.

d) No maintenance cost for cleaning so while having direct contact heater there is no need to provide stand by heater.

e) Reduced Retention time leading to lower sugar losses.

f) In direct contact heater head loss become zero so it reduces the power requirement of the pump.

g) Lower structural requirement.

Disadvantages:

a) The condensate of the heating media(vapour) added along with heated media(juice) so it was extra load on evaporation system.

b) Operation should take care while using low pressure vapours (3rd or 4th body vapours) as a heating media to avoid entertainment

Direct Contact Heater (DCH) Design calculation:

Required data for calculation:

1) Juice flow rate in T/ hr

2) Specific heat of juice in Kcal/ kg/oC

3) Temperature of inlet juice in oC

4) Temperature of outlet juice in oC

5) Temperature of heating vapour in oC

6) Velocity of the inlet juice in m/sec ( Juice came from pump pressure than it having 1.6 to 2.0 m/sec and juice came with gravity from another DCH than it having 1 to 1.1m/sec)

7) Velocity of the outlet juice in m/sec ( Outlet of the juice taken as gravity flow so it having 1 to 1.1m/sec)

8) Velocity of vapour at the DCH inlet point in m/sec (Depending on bleeding vapour )

9) Velocity of vapour at annulus in m/sec ( Generally it having 10m/sec)

10) Velocity of NCG in m/sec ( NCG vapour velocity lies 10 to 20 m/sec)

11) Top Baffle Angle in Deg. ( For better distribution of the juice it will take 130deg)

12) Bottom Baffle Angle in Deg. ( For better distribution of the juice it will take 120deg.)

13) Bottom Cone Angle in Deg. ( For free removal of the juice it will take 55 to 60deg.)

14) Number of Baffles in the DCH ( It is to be take minimum 2 no.s of each top and bottom baffle)

15) Shell thickness in mm.

16) Latent Heat of inlet Vapour(heating media) in kcal/kg

17) Specific Volume of inlet Vapour(heating media) in M3/kg

Find Latent Heat and Specific Volume purpose go through the following link Online Steam Table For Saturated steam

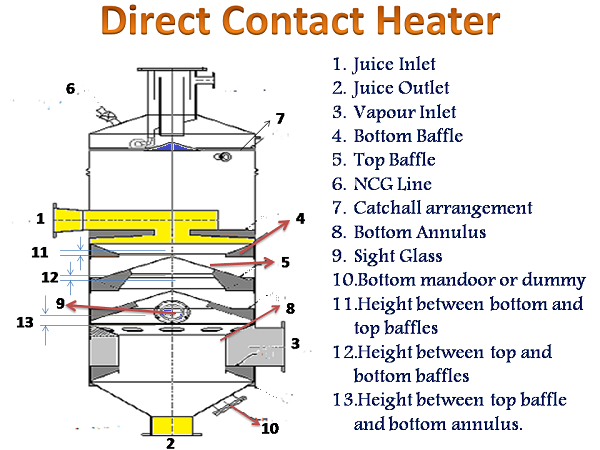

Formulas for Calculation:

- Vapour Quantity (requirement of the heating) in T/hr = [(Juice Quantity x Specific heat of the juice x ΔT) / Latent heat of vapour ]. (Note : In the place of latent heat do not take total heat of the heating media, it is be take the value Latent heat of vapour + (Sensible heat of vapour – Final temperature of the heated media). For example take heating vapour temperate having 116oC and heated media final temperature got 114oC than it is to be take [ 528 + (116-114)]

- Vapour Quantity in M3/sec = Multiplying with Specific volume of vapour.

- Vapour inlet line dia = SQRT [ ( vapour Qty in M3/sec x 4) / (π x Velocity of inlet vapour) ].

- Juice inlet line Dia = SQRT [ ( Juice inlet Qty in M3/sec x 4 ) / (π x Velocity of inlet juice)].

- Juice Outlet line Dia = SQRT ( (Juice inlet Qty + Condensate Qty in M3/sec) x 4 / (π x Velocity of outlet juice in m/sec). (Note: here condensate is equal to vapour quantity)

- Dia of NCG vent = SQRT (Qty of NCG vapours in M3/sec x 4 / (π x Velocity of NCG in m/sec). ( Note : The quantity of NCG vapour will take 1.5% to 2% on quantity vapours)

- Dia of bottom baffle = SQRT ( Vapour Qty in M3/sec x 4 / (π x Velocity of vapour at annulus in m/sec).

- Dia of bottom annulus = Dia of bottom baffle

- Dia of top baffle = Dia of bottom baffle + (100mm to 120mm)

- Dia of the shell = SQRT [ (Dia of bottom baffle)2 + (Dia of top baffle)2]

- Height of the bottom cone = Tan φ [(ID of Shell dia – juice outlet dia)/2] ( (Here φ = Bottom cone in Deg.)

- Height of the bottom baffle = Tan φ [(ID of Shell dia – Dia of bottom baffle) / 2] ( (Here φ = Bottom Baffle Angle in Deg.)

- Height of the top baffle = Tan φ [(Dia of top baffle) / 2] ( (Here φ = Top Baffle Angle in Deg.)

- Height of the bottom annulus = Dia of the vapour inlet + (50 to 100mm)

- Gap between top and bottom baffles : It is to be calculate juice quantity and its velocity in the inside of the vessel to area availability between top and bottom baffles. It is nearly having 40 to 60mm.

- Gap between bottom and top baffles : It is to be calculate according juice velocity in the inside of the vessel to area availability between bottom and top baffles. It is nearly having 25 to 50mm.

- Height of the top cone : As per designer it may give flat type or slight cone type design. ( for below 1100mm shell dia it will take 175mm and above 1100mm dia will take 345mm)

- Height of the vapour space above the baffle arrangement (catchall) : Vapour space height consider 1500mm to 2000mm.

- Height between top baffle and bottom annulus = It is to be calculate as per area availability for vapour and juice quantity in the inside of the vessel. It is nearly having 200 to 250mm.

- Gap between Juice inlet and bottom baffle : It is required for equally distributing of the juice in the vessel so it will take 200 to 250mm.

- Total height of the heater : Height of the top cane+ Height of the vapour space above the baffle arrangement + Dia of the juice inlet + Gap between Juice inlet and bottom baffle + (Number of baffles x Height of the bottom baffle) + (Number of baffles x Height of the top baffle ) + (Number of baffles x Height between bottom and top baffles) + (Number of baffles x Height between top and bottom baffles) + Height between top baffle and bottom annulus + Height of the bottom annulus + Height of the bottom cone.

Impotent Consideration in series of Direct Contact Heaters with different types of bleeding vapours:

a) The inside vessel of DCH sealing to be provided for lateral DCH while using different types of bleeding vapours .( For example three numbers of direct contact heaters are in a series than we must provide sealing for juice inlet in 2nd DCH and 3rd DCH.

b) The sealing tank area can be take as double of the cross section area of the juice inlet line. The volume of the sealing tank will be calculating according to pressure differences of the inlet vapours from DCH to DCH.

c) Provide one bypass line from sealing tank to outlet juice line with valve control to drain the juice while plant stoppage.

d) Another impotent parameter is to be provide proper elevation from the DCH to DCH. The elevation can be calculate from pressure differences of the inlet vapours from DCH to DCH.

( For example Take one “Quintuple effect evaporator” and DCH1, DCH2 having 4th and 3rd bleeding vapours respectively. Now according to pressure drop calculations the maximum pressure drop from 3rd to 4th body vapours can be 0.42 abs Kg/cm2.)

e) Elevation requirement =( Vacuum in mtr of Hg x Mercury density / Heated media density).

f) So 0.42 abs Kg/cm2 = { 760 – } = 451mm of Hg

g) Elevation requirement = = 5.8mtrs ( It is better to take 1 to 1.2mts extra on calculated value to avoid the fluctuation in evaporator set)

Online Calculator for Direct Contact Heater (DCH)

Related Topics

Tubular juice heater design calculation with online calculator

Formulas and design consideration parameters in Robert Evaporator Design and also provided online calculation sheet with formulas.

Condensate or Duplex Heater (Liquid- Liquid Heater) heating surface, number of tubes, tube plate dia, pressure drop calculation formulas with online calculation sheet.

Juice Clarifier Flash Tank design parameters like dia of the flash tank, juice inlet and out line sizing, flash vent pipe sizing ..etc.

Design Calculation of Juice Defecator and Sulphitor with online calculator.

Heat Transfer Coefficient of Liquid -Liquid Tubular Heater Calculation| HTC

Flash Vapour Calculation | Flash Vapour Recovery Vessel Design Calculation.

Hi friends Thanks for reading. I Hope you liked it. Give feed back, comments and please share it.

31 thoughts on “Direct Contact Heater (DCH) Design Calculation with Online Calculator”

Subodh Rana

(April 20, 2017 - 4:30 pm)Dear Shiva Sir,

I think there should be one top baffle immediately under the juice inlet rather than the bottom baffle. Otherwise how the juice reaches to the bottom baffle # 4 as shown in the dwg.

siva alluri

(April 21, 2017 - 12:12 pm)Thank you subodh rana sir for gave valuable comment. Actually at the entry of the juice provided juice distribution arrangement, so it is not a bottom baffle I showed simply in dwg. in yellow colour for juice and it was distributing equally all sides of the DCH.

Kishore

(April 22, 2017 - 12:15 am)I don’t understand what you are saying about gap between top and bottom baffle and gap between bottom and top baffle.actually the gap between baffle in dch will be around 400mm

siva alluri

(April 22, 2017 - 5:36 am)Thank you for commenting sir, The gap between top and bottom baffle means distance between top and bottom baffle at shell corner side. Gap between baffle = Height of the top baffle + height of the bottom baffle + gap between top and bottom baffle = 101+151+40=292mm (Taken from above example in calculator).

Thomas

(September 15, 2017 - 9:39 pm)Great post! Have nice day ! :) ahnyk

PRANJAL SAXENA

(June 30, 2018 - 6:50 am)DEAR SIR PLEASE GIVE SOME MORE DETAILS ON CALCULATION OF THE HEIGHT OF BOTTOM BAFFLE BECAUSE THERE IS LOT OF DIFFERENCE BETWEEN MY ANSWER AND CALCULATOR ANSWER AND WHAT VALUES TAKEN IN CALCULATOR BECAUSE THEY DID NOT MATCH WITH THE ANSWER.

THANK U

José Ricardo Pérez

(October 17, 2017 - 7:54 pm)Wath is catchall positio n7?

siva alluri

(October 19, 2017 - 12:32 pm)Depend upon the vapour pressure the catchall height(Vapour space height consider) vary from 1000 to 1800mm

narendra jain

(March 29, 2018 - 11:21 am)it is good design to provide catchall as shown.it should be robust design to avoid entrainment at all.

siva alluri

(March 30, 2018 - 3:43 pm)Thank you Mr narendra jain

Vijay narade

(September 18, 2018 - 11:48 am)I want to know, how much height is required for clear juice dch?

siva alluri

(September 18, 2018 - 2:53 pm)Clear juice DCH height depended upon the 1st body top tube plate elevation ( For Robert type body) and its body vapour pressure

Suppose 1st body pressure – 0.8 kg/cm2 and body top tube plate elevation from FFL – 6 mtrs ( If it is FFE then consider bottom tube plate elevation or If SK body then consider average juice level of that body from FFL)

Then DCH bottom cone elevation = 6 + 8 ( 0.8 x 10 )= 14 mtrs

sunil khandekar

(December 22, 2018 - 5:20 am)Give me Batch vacuum Pan design calculation formule

siva alluri

(December 23, 2018 - 1:32 pm)Ok Mr.sunil khandekar

We will provide soon

NEERAJ KUMAR RAJPUT

(May 15, 2019 - 3:52 pm)Sir please design

ion exchange coloum for sugar refinery

ankit kumar

(May 24, 2019 - 10:05 am)Dear sir

please calculate vapour load in DCH on the basis of Enthalpy instead of Latent heat.

siva alluri

(May 25, 2019 - 4:33 pm)Use fundamental formula

i.e Q x Cp x ∆T for juice

For vapour consider total heat in-place of latent heat

Manil kumar

(May 28, 2019 - 4:31 pm)Sir how to think about the dilution for chemical preparation in sugar refinery.

siva alluri

(May 30, 2019 - 5:05 pm)which chemical dilution you wont

manil kumar

(July 12, 2020 - 2:07 pm)sir my question about phosphoric acid dilution.

Vijay Annaso Narade

(July 19, 2019 - 9:41 am)Can u provide organic chemistry of juice, treated juices, sugar?

siva alluri

(July 31, 2019 - 4:06 pm)Please refer

PRINCIPLES OF SUGAR TECHNOLOGY by PIETER HONIG

Vinay kumar

(March 21, 2020 - 6:00 pm)Dear sir pls. Provide the calculation of altitude of single dch installed on third body vapour for raw juice heating

AMIT KUMAR

(July 3, 2020 - 6:46 am)Dear Sir

can we operate DCH of raw juice heating from 65 to 75 c with fifth vapour with 78 c temp and pressure .72 kg. and also vapour going to tabular heater. T heater on ejector

siva alluri

(July 5, 2020 - 3:54 am)We can operate DCH by last effect vapors also with proper removal of NCG gases with standby condenser. Now some industries used continuous pan vapors used for 1 st heating of raw juice.

Mohan Shete

(July 26, 2020 - 11:18 am)Give me formula for lime dosing to juice sulphitation .at how much distance we can point out a location to lime dosing on juice line

siva alluri

(August 12, 2020 - 4:06 am)The better results in reaction tank the addition point should be 9 sec before of the juice reaction tank juice entry

zahir sayyed

(October 19, 2020 - 12:41 pm)Sir, if we could create animation for all equipment. One could easily understand process if illustrate flow of Vapor / Juice passing thru Inlet / Outlet

Sharvan Tyagi

(July 24, 2022 - 4:34 am)Dear sir,

I want to know difference between direct contact molasses conditioner and DCH design and what is criteria define to decide height of DCH & Molasses conditioner.

Amit Gupta

(October 12, 2022 - 4:22 am)Sir, pls suggest the book where i can find the DCH height calculation in brief ?

Sanjay Tandon

(July 8, 2023 - 10:29 am)Peter Rein has given the brief calculations of DCH in his book “Cane Sugar Engineering” , it may be helpful for you.