In this session discussed about Activated Sludge Process meaning, Principles of operation, Process description, important parameters and features for industrial wastewater treatment.

Aerobic Process in Wastewater Treatment| Activated Sludge Treatment

Meaning Activated Sludge Process

The activated sludge process is one of the biological method of industrial waste waste treatment. The activated sludge process consists of converting the suspended and particulate organic matter in the raw waste water into harmless end products and new cells growth with the help of Anaerobic and Aerobic Microorganisms.

In this process Activated Sludge is developed when these micro-organisms are allowed to coagulate with the organic matter in the waste water to form “Flocs’.

Under the activated sludge treatment process, the biodegradable organic matter is consumed by a mass of micro-organisms under aerobic conditions, resulting in:

1. Micro organisms consuming oxygen to satisfy their energy demand.

2. Formation of excess sludge generated from a surplus of living and inert matter in the wastewater.

3. BOD and COD of the effluent is reduced maximum to the extent of 80 % and 65 % respectively.

Principles of Operation

a) This is the actual process of bio-degradation where the coagulated organic matter is acted upon by the micro-organisms and converted to harmlessed products and new cell tissue/cell matter.

b) A portion of these settled active organisms that flow out of the aeration/reaction tank with the treated water is returned to the tank to mix with the incoming waste water and provide continuous reseeding. This mixture of raw waste water and the returned activated sludge is called as the mixed bacteria.

c) The organisms live by using oxygen and work by adsorbing and absorbing the food matter. Oxygen is used to provide energy for the cell growth and produce CO2 and H2O as the final by products. Cell growth provides new organisms for the self sustenance and continuation for the process.

d) The microbes are composed of two kinds of species. The ‘Floc forming’ type which trends to settled easily in the clarifiers and the “Filament Formers” which do not have sufficient time to settle, Float on the surface of the tank and are carried out along with final effluent. Hence the presence of these organisms is not desirable in the system.

d) The excess amount of sludge produced from the system has to be washed regularly to maintain the normal balance of the process.

e) The activated sludge system efficiency depends on pH, temperature, air contact, suspended solids, culture growth, concentration of floc, that is optimum mixed liquor suspended solids concentration ( MLSS).

Activated Sludge Process Description

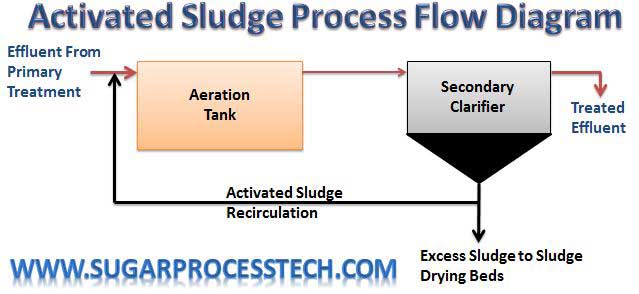

a) This process comprises of Aeration tank followed by Secondary Clarifier. In aeration tank organic load will be degraded by the help of cultivated microbial culture.

b) Constant MLSS (Mixed Liquor Suspended Solids) will be maintained in aeration tank by recycling the activated sludge trapped by the secondary clarifier.

c) Recycling of bio-sludge will be done by non-clog, centrifugal, semi open type continuous duty suitable Sludge Recirculation pump. Oxygen is supplied at Aeration Tank by air from the proposed Air Blower. At aeration tank diffusers are provided with effective length for an even distribution of air. Nutrients will be dosed at aeration tank for growth of bacteria.

d) The excess sludge from the secondary clarifier is withdrawn to sludge drying beds. Here sludge gets dried and form cakes. It can be used as good manure or for land filling.

Some Important parameters in activated sludge treatment

Mixed Liquor Suspended Solids (MLSS)

1. The mixed liquor Suspended Solids (MLSS) is the amount of solid, particulate matter present in the “Mixed”. (i.e.) the mixture of Activated Sludge and Raw Wastewater.

The MLSS is used as an important parameter to design and control the operation of the aeration system.

2. A high MLSS concentration and long aeration period are the two important criteria essential for the proper functioning of the “Extended Aeration” System.

3. Maintenance of the MLSS level is very important for optimum treatment of the incoming effluent stream. If the MLSS concentration decreases, the sludge wasting should be decreased, to increase the concentration of MLSS in the aeration lagoon.

4. Conversely, if the MLSS concentration increases, the wasting of sludge is also increased to restore the balance of MLSS in the tank.

Sludge Volume Index (SVI)

1. Sludge Volume index is the ratio of the percent of settled volume of sludge to the percent weight of MLSS in gms.

2. It is measure of the settleability of the activated sludge, and indicates the degree of concentration and the physical state of the sludge.

3. An SVI range of 50-100 indicates proper settling of the sludge, and the healthy operation of the plant. When the SVI is more than 150, it indicates that the sludge settlement is not proper, and at a value of 200, the problem of “Sludge Bulking” begins. The methods of control of SVI values are by controlling the MLSS concentration an flow of effluent/return sludge in the aeration lagoon.

4. An SVI value above 100 means the amounts of sludge waste has to be increased, and the quantity of ‘Return Active Sludge’ from the clarifier/settling tank should be reduced.

Food to Microorganism ratio ( F/M)

The relative amounts of in coming food (waste) and micro-organisms in the mixed liquor is referred to as the F/M Ratio (Food to Micro-organisms Ratio) and controls how well the process performs.

MLVSS – Mixed liquor volatile suspended solids.

MLVSS is the concentration of volatile suspended solids in the aeration basin of an activated sludge system.

Cell Residence time ( CRT)

The average length of time days that an oranism remains in the secondary treatment.

CRT (Cell residence time) days = Total MLVSS in kgs / Total MLVSS wastes kgs/day

The CTR for facility is controlled/maintained by wasting the appropriate amount of excess biomass.

Conventional activated sludge

Aerator Detention time 4 to 8 hrs

F/M ratio – 0.25 to 0.45

CRT – 4 to 6 days

Extended aeration activated sludge

Aerator Detention time 16 to 24 hrs

F/M ratio – 0.05 to 0.15

CRT – 15 to 25 days

The microbial culture concentration is to be maintained in the rage of 1500 to 4000 mg/l.

Nutrient Dosing

Hence initial culture development and maintained of activated sludge rate by re-circulation of sludge and addition of cow dung, Urea, DAP and their mixing are essential.

The nutrient dosing shall be maintained in ratio of BOD : N : P = 100 : 5 : 1

For example : Effluent Flow rate – 500 m3/day with BOD – 600 mg/liter at the inlet of aeration treatment process and outlet BOD required 240 mg/liter.

Flow rate – 500 m3/day

Inlet BOD – 600 mg/liter

Outlet BOD – 240 mg/liter

BOD removal = ( Inlet BOD – Outlet BOD ) in mg/ liter = 600 – 240 = 360 mg/lt = 0.36 kg / m3

Total BOD load on anaerobic system = Effluent flow rate in m3/ day x BOD load in kg/ m3

= 500 x 0.36 = 180 kgs

BOD : Nitrogen : phosphates = 100 : 5 : 1

i.e 100kg BOD : 5 kg Nitrogen : 1 kg phosphorous

For 180 kg BOD,

Nitrogen required = 180 x 5 / 100 = 9 kg /day

Phosphate required = 180 x 1 /100 = 1.8 kg/day

Once maintained the activated sludge in aeration thank then requirements of nutrients are very less or not required.

Features of Activated Sludge Process

1. The activated sludge system requires less area than the lagoon systems and effluent standards can be met without major storage capacity for the lagoons.

2. Waste water treatment takes place at the same time as the processing system has less retention time.

3. Treated effluent can be recirculated in order to replace fresh water for the production process or used for any irrigation requirements if the plant site topography permits.

4. The system incorporates electro-mechanical works in form of aerators. These are an additional cost, require regular attendance.

5. The system can be designed to meet the effluent water quality criteria of World bank, National Environment authority.

Thank you for reading this article “ Activated Sludge Process for Wastewater Treatment”. We hope that, this article was full filled your requirement. Give feed back, comments and please share it.

Related Article

Anaerobic Treatment Process for Industrial Waste Water

Various methods for Industrial Effluent Treatment Plant

Biomethanation Process for Distillery Spent Wash Treatment

Continuous Stirred Tank Reactor (CSTR) Design Criteria | Anaerobic Digester

Fundamental Concepts of Overall Heat Transfer Coefficient (OHTC)

Manufacturing Process of Bagasse or Biomass Briquettes

Hydrostatic Head in Evaporator Bodies and Vacuum Pans

8 thoughts on “Activated Sludge Process for Wastewater Treatment | Anaerobic Digestion”

Hanamant

(January 13, 2020 - 9:28 am)Very good explanation of sugar etp

siva alluri

(January 19, 2020 - 2:03 pm)Welcome

Sundararajan

(March 8, 2021 - 7:24 am)This article is very important for me and I am very much interested in STP

Thanks a lot

Sundararajan

siva alluri

(March 16, 2021 - 6:27 am)Welcome

Dinesh kumar

(March 22, 2021 - 2:09 pm)Hi

Hanamant

(June 22, 2022 - 1:37 am)Very good explanation of activated sludge process. Please contact number send me

siva alluri

(June 26, 2022 - 2:22 pm)welcome sir

V Jagtap

(February 10, 2023 - 10:44 am)Sir please help me, please tell me can we use Aerobic Activated Sludge Process for Sugar Effluent Treatment Plant.

Please guide me.

Thanking you and looking forward to hear from you soon,

Regards,

JAGTAP