Flocculation stands as a remarkable process that plays an essential role in the removal of suspended solids from wastewater. In this article, we’ll explore what flocculation is, how it works, and where it is employed in wastewater treatment.

Understanding Flocculation:

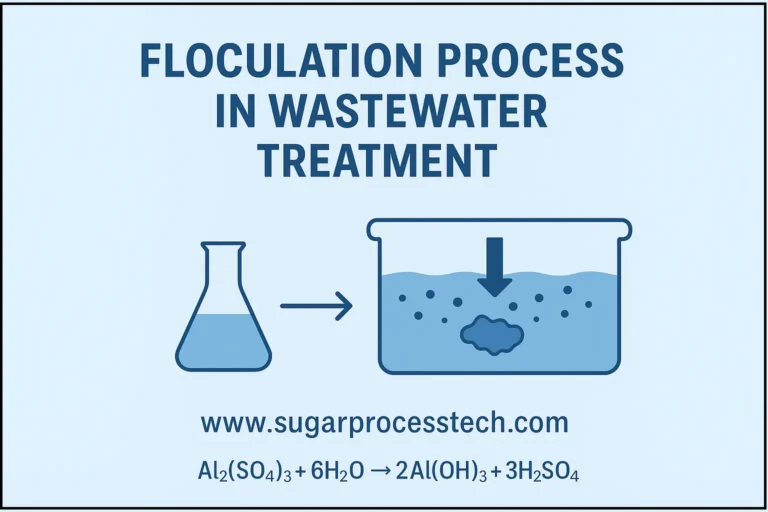

Flocculation is a chemical process used to aggregate small solid particles and colloids suspended in wastewater, causing them to form larger, heavier masses known as flocs. These flocs are easier to separate from the water through the sedimentation or filtration process in water treatment.

The Key Stages in the Flocculation System:

- Coagulation: In this initial stage, coagulants like aluminum sulfate are added to neutralize the negatively charged solid particles in the wastewater.

- Rapid Mixing: After dosing of coagulants, rapid mixing is employed to disperse coagulants uniformly throughout the wastewater. Coagulants are substances like aluminum sulfate that help neutralize the negatively charged solid particles, enabling them to gather together.

- Slow Mixing: Once the coagulated particles are dispersed, slow mixing takes over, facilitating the growth of flocs. This slow and gentle agitation encourages the particles to clump together, making them easier to remove.

- Polymer Addition: In the later stages of flocculation, a polymer chemical is added to the wastewater. Polymers bridge the flocculant from micro to macro flocculant, making the mass of particles get bigger. This chemical also binds the collected mass together so that it does not easily disintegrate.

- Sedimentation or Filtration: After flocculation is complete, the large solid masses can be removed from the wastewater stream through settling, where the floc drops to the bottom for removal or through the use of settling or filtration.

The Flocculation Process:

Proper flocculation relies on several critical factors, including detention time (stirring time), mixing intensity, and the basin’s shape. If these factors are not carefully considered, the collision of particles may be ineffective, leading to poor floc formation. Extreme mixing can even result in the tearing of flocculated particles that have already clumped together.

Detention time is particularly important during flocculation as it allows the flocs to grow and become more substantial. Generally, detention times of 5-20 minutes are adequate for direct filtration, while conventional filtration may require up to 30 minutes.

Types of Flocculators:

Two widely used types of flocculators are:

- Hydraulic Flocculators: These harness the kinetic energy of water flow, usually created by baffles, to promote mixing. Examples include horizontal flow baffled flocculators, vertical flow baffled flocculators, Tangential Type Flocculator, Pipe Flocculator and more.

- Mechanical Flocculators: These devices consist of rotating paddles with horizontal or vertical shafts or paddles suspended from horizontal oscillating beams that move up and down.

Design Parameters:

- Hydraulic and Gravitational Flocculators:

- Velocity in the channel should range from 10 to 30 cm/s.

- The channel’s width must be a minimum of 45 cm.

- Flow depth should not be less than 1 meter.

- Flocculation detention time typically falls between 10 to 20 minutes.

- Loss of head ranges from 15 to 60 cm.

- Mechanical Flocculators:

- Power requirement is around 0.5 to 1.5 watts per cubic meter per flow per hour.

- Peripheral velocity of paddles should be in the range of 0.15 to 0.6 m/s (average of 0.35 m/s).

- The flocculation period generally takes 20-30 minutes.

- Tank depth is typically 3 meters to 4.5 meters.

- Flow velocity is around 0.4 m/s.

- The velocity gradient varies from 10 to 80 per second.

- The Gt (gradient time) value falls between 104 to 105.

- Power consumption ranges from 10 to 36 kW per square meter per day.

- CD (Newton’s Coefficient of Drag) is generally 1.8.

- The K value is 0.25 in the absence of a stator.

- The n value is between 1 to 5 RPM.

Summary: Flocculation system in wastewater treatment is an essential process, where fine suspended particles are transformed into larger flocs for easier removal. It ensures clean water, protects aquatic ecosystems, and supports sustainable environmental management.

Thank you for reading this article—please share your feedback and leave your comments below!

Related Article:

Difference between Coagulation and Flocculation in Water Treatment

Classification of Impurities Present in Water Related to Industrial Application

Chemical Oxygen Demand (COD): Meaning, Applications, and Control Strategies

Basic concepts of the Raw Water treatment system used in industrial applications

ETP | Sugar industry effluent treatment plant process philosophies

Anaerobic Digestion | Activated Sludge Process for Wastewater Treatment

Anaerobic Treatment Process for Industrial Waste Water

Various methods for Industrial Effluent Treatment Plant

Distillery Spent Wash Treatment by Biomethanation Process

Anaerobic Digester |Continuous Stirred Tank Reactor Design Criteria | CSTR