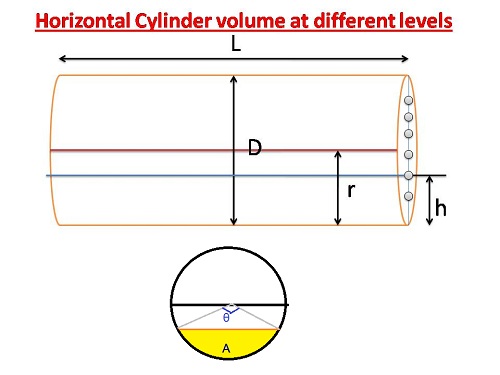

Evaluate Volume of vacuum crystallizer at different sight glasses (Horizontal Cylinder volume at different levels)

To find the vacuum crystallizer volume (Horizontal Cylinder volume at different levels ) at different sight glass levels using by two types of formulas

One is used for material having upto center point of cylinder (i e Massecuite having below or upto the center shaft of crystallizer, or radius of cylinder ≥ height of material level from the bottom of Cylinder).

Another formula is using to find volume material having above the center point of cylinder. (i.e Massecuite having above the center shaft of crystallizer or radius of cylinder ≤height of material level from the bottom of Cylinder).

Formula for Massecuite having below the center shaft of crystallizer

Data to be required for calculation:

Dia of the Crystallizer (Horizontal Cylinder) = D (mtrs)

Horizontal Length of Crystallizer (Horizontal Cylinder) = L (mtrs)

Sight glass height from the bottom of the crystallizer (height of material level from bottom Cylinder) = h (mtrs)

Calculation to be done :

Radius of cylinder = r = D/2 (here r>h)

Angle =θ = 2 cos -1 ((r – h)/r )

Peripheral length =c = 2 √ h (2r – h )

= l = 0.01745 x r x θ

Area =A = 1/2 (rl – c( r – h))

Volume= V =A x L

Formula for Massecuite having above the center shaft of crystallizer

Data to be required for calculation:

Dia of the Crystallizer (Dia Horizontal Cylinder) = D (mtrs)

Horizontal Length of Crystallizer (Horizontal Cylinder) = L (mtrs)

Sight glass height from the bottom of the crystallizer (height of material level from bottom Cylinder) = h (mtrs)

Calculation to be done:

Radius of cylinder = r = D/2 (here r<h)

Angle = θ = 2 cos -1 ((h -r)/r )

Peripheral length =c = 2 √ h (2r – h )

= l = 0.01745 x r x θ

Area =A = 1/2 (rl – c( h – r))

Volume = V =A x L (M3 )

Online Calculator for calculating volume of Horizontal Cylinder volume at different levels (Vacuum Crystallizer volume for different sight glasses levels)

(Note : In this calculator central shaft volume considered when material should be having above the central shaft level. While calculator using for finding volume of horizontal cylinder than enter the values “Zero” in central shaft length and dia cells)

Please click here

Related Articles

Formulas for Sugar Industry boiling house stock calculation.

NPSH calculation,NPSHa,NPSHr formulas, Pump cavitation , Pump suction and delivery lines head loss.

Find liquid volume for vertically mounted cylindrical volume and also find the volume in cylindrical tank partitioned portion.

Circle segment area , arc length, chord length Formulas with online calculation.

Definitions in Steam Properties and Online Steam Table For Saturated steam.

Overall heat transfer coefficient for shell and tube heat exchanger.

Hi friends Thanks for reading. I Hope you liked it. Give feed back, comments and please share it

2 thoughts on “Formula to find volume of Horizontal Cylinder volume at different levels”

HR Yadav

(July 20, 2023 - 11:28 am)R/sir

I am sugar technologist, working in Nepal. I always use to read your articles comes time to time in this site. This is very usefull site for technologists to develop their technical knowledge.

Thanking you

siva alluri

(July 21, 2023 - 5:27 am)Thank you