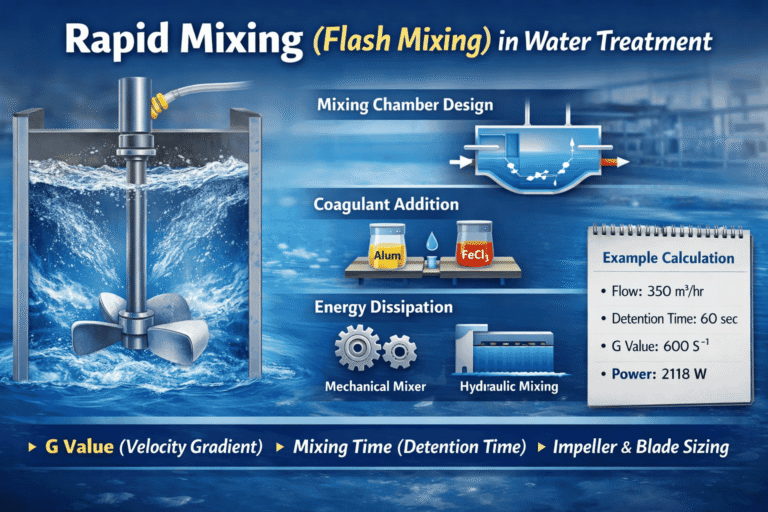

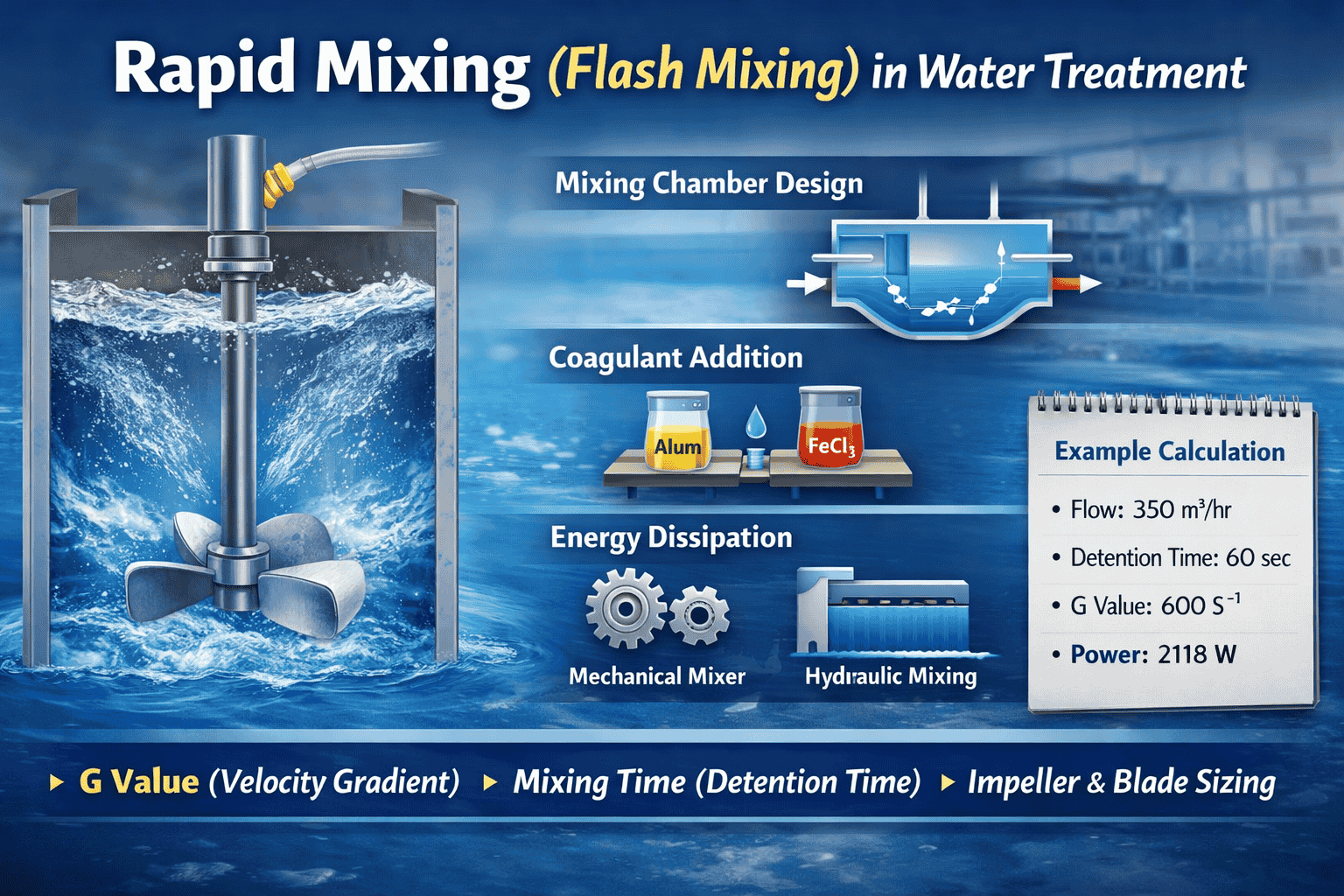

Rapid Mixing or Flash mixing mechanisms play an essential role in the coagulation and flocculation process of the water treatment system.

To achieve efficient coagulation, it is essential to ensure the rapid and uniform dispersion of chemicals throughout the water volume. This process, where coagulants are rapidly mixed to achieve such dispersion, is referred to as Rapid Mixing or Flash Mixing.

Key Components of Rapid Mixing or Flash Mixing

Mixing Chamber Design

Mixing Chamber Design should consider factors such as inlet and outlet configurations, material selection for construction, and hydraulic characteristics. The chamber’s geometry, including the shape and size of the mixing zone, plays a crucial role in achieving efficient and uniform mixing.

Coagulant Addition

Coagulant Addition is another crucial component. Selecting the appropriate coagulant and determining the optimal dosing technique are essential. It’s also important to consider coagulant mixing strategies, which can vary based on the type of coagulant being used.

Energy Dissipation

Energy Dissipation is necessary to facilitate mixing. This can be achieved through mechanical mixers or hydraulic pump systems. The choice between a flash mixer (mechanical) and in-line mixing (hydraulic) depends on various factors, including the water treatment plant’s design and requirements.

Designing Rapid Mixing Units for Flocculation:

For effective flocculation, rapid mixers involve determining the proper tank dimensions, mixer types, and power requirements. Here’s a glimpse of the key design parameters for rapid mixers:

1. Mixing Devices:

Rapid mixers come in various types, including impeller-based mechanical mixers, inline blenders, hydraulic methods, and air mixers. The selection depends on factors like power input, tank dimensions, and the desired velocity gradient.

- Mechanical Devices in Dedicated Basins: Impeller-type mechanical mixers, mounted on vertical or inclined shafts, are commonly used for rapid mixing. They are efficient and provide good control over mixing.

- Inline Blenders: These systems use perforated tubes or nozzles to disperse chemicals directly into the water. They offer uniform distribution but may require adjustments.

- Hydraulic Methods: Hydraulic mixing utilizes structures like weirs, Parshall flumes, or throttled valves to induce turbulence and mix chemicals. It is suitable for high-energy systems.

- Air Mixing: Air can also be used to induce mixing in water treatment processes, albeit less commonly.

2. Mixing Intensity (G Value)

Mixing Intensity (G Value) is a key parameter that characterizes the energy input during rapid mixing. It is a measure of the relative velocity gradient and is crucial for effective coagulation. Factors affecting G value include the type of coagulant, coagulant dose, and hydraulic conditions. Calculating G values helps ensure optimal coagulation.

Velocity Gradient (G): The mixing intensity is governed by the velocity gradient (G), calculated using the equation

![]()

The above formula governed by the velocity gradient equation developed by Camp and Stein.

- G is the mixing intensity or Root mean square velocity gradient (in s^-1 or 1/s).

- P represents the power input to the mixing system (in watts).

- μ stands for the dynamic viscosity of the fluid being mixed (in N·s/m^2 or Pa·s).

- V denotes the volume of the fluid being mixed (in m^3).

The following formula is also using for calculating the mixing intensity, often referred to as the G value.

![]()

Where:

- G is the mixing intensity (in s^-1 or 1/s).

- N represents the impeller rotational speed in revolutions per second (in s^-1).

- P denotes the power input to the mixing system (in watts).

- D stands for the impeller diameter (in meters).

3. Mixing Time or Detention time.

Mixing Time is closely related to G value and describes the duration required for coagulation to take place. Achieving the desired floc formation depends on adequate mixing time. Understanding the relationship between mixing time and G value is crucial for efficient rapid mixing.

Normally, Mixing time and the G value have a direct relationship. This means that, in general, as the G value increases, the required mixing time decreases. In other words, a higher G value results in more efficient mixing and faster coagulation.

Here given table for thumb rule guidance for relationship between velocity gradient and mixing time

| Detention Time (t0) (s) | G (s^-1) |

|---|---|

| 0 – 5 | 4000 |

| 10 – 20 | 1500 |

| 20 – 30 | 950 |

| 30 – 40 | 850 |

| 40 – 130 | 750 |

Design Basis for Impeller Mixers:

Impeller-type mechanical mixers are widely used for rapid mixing in water treatment. Here are some design considerations:

- Impeller Speed (RPM): Typically ranges from 400 to 1400 RPM.

- Detention Time: Recommended between 30 to 60 seconds.

- Power Requirements: 1 to 3 watts per M^3/hr of flow.

- Impeller Diameter: Ratio to tank diameter usually between 0.2 to 0.4.

- Shaft speed should be greater than 100 rpm and tangential velocity at the tip of the blade should be greater than 3 m/s.

Design Steps:

- Determine Tank Dimensions: Calculate the tank’s volume using the flow rate and desired detention time. Then, find the tank’s diameter using the depth-to-diameter ratio.

- Compute Power Requirements: Use the power formula to calculate the power required for efficient mixing.

- Determine Blade and Impeller Dimensions: Impeller diameter is based on the tank diameter. Blade area can be calculated using specific formulas.

- Use Vertical Strips or Baffles: Install baffles along the tank walls to prevent vortex formation or excessive rotational movement of water.

- Tank Height-to-Diameter Ratio: Suggested range is 1:1 to 3:1 for proper dispersion.

- Tank Dimensions: The tank dimensions are determined based on the desired volume and detention time. For example, volume = Flow (m³/hr) * detention time (hours).

- Impeller Diameter: The diameter of the impeller depends on the impeller ratio to the tank diameter, which typically ranges from 0.2 to 0.4. A proper balance is required to ensure effective dispersion.

- Depth and Width: For a uniform velocity gradient, the depth of the tank should be equal to the width.

- Paddle Velocity: The paddle velocity should not exceed 1 m/s to prevent excessive velocity gradients.

- Power Requirements: The power required is calculated based on fluid power, which is the product of μ, G^2, and V.

- Blade and Motor Efficiency: Blade and motor efficiencies are essential for precise power input calculations.

- Vortex Prevention: To avoid vortex formation, vertical strips or baffles should be provided in the tank.

Example for Rapid mixer design mechanisms of coagulation

| S.No | Description | UOM | Values | Remarks |

| I | Input Parameters | |||

| 1 | Design flow to be treated | M3/hr | 350 | |

| 2 | Detention time | seconds | 60 | 30 to 60 sec |

| 3 | Ratio of tank Height to diameter | % | 1.5 | The recommended ratio will be around 1:1 to 3:1 for proper dispersion |

| 4 | Dynamic viscosity ( µ) | N s /M2 | 0.0010087 | |

| 5 | Ratio of impeller Diameter to tank diameter | % | 0.4 | Impeller diameter to ratio of tank will be around 0.2 to 0.4 |

| 6 | Rotational speed of impeller | rpm | 120 | Greater than 100 rpm |

| 7 | Velocity gradient ( G) | S-1 | 600 | >300 S-1 |

| 8 | Newton Drag Coefficient ( C) | 1.8 | ||

| 9 | Density of water (Dw) | kg/m3 | 1000 | |

| II | Calculation Part | |||

| II A | Holding Volume of the mixer tank | |||

| 1 | Volume of the mixer tank | M3 | 5.83 | |

| 2 | Volume of the mixer tank | 1.1775 D^3 | ||

| 3 | Diameter (D ) | M | 1.70 | |

| 4 | Height of the tank | M | 2.56 | |

| II B | Calculating Power Requirements | |||

| Formula | P= µ G2 * V | |||

| 1 | Velocity gradient ( G) | S-1 | 600 | |

| 2 | Dynamic viscosity ( µ) | N s /M2 | 0.0010087 | |

| 3 | Volume of the mixer (V) | M3 | 5.83 | |

| 4 | Power requirement (P) | Watts | 2118.3 | |

| 5 | Power per unit volume of tank | Watts /M3 | 363.1 | |

| 6 | Power per unit flow of water | Watts /M3/Hr | 6.052 | |

| II C | Determining the dimensions of Impeller & Blades | |||

| 1 | Power requirement (P) | Watts | 2118.3 | |

| 2 | Diameter of impeller | M | 0.682 | |

| 3 | Velocity at the tip of impeller | m/s | 4.282 | |

| 4 | Newton Drag Coefficient ( C) | 1.80 | ||

| 5 | Relative Velocity (VR) | m/s | 3.212 | (75% of tangential velocity) |