Refined Sugar Manufacturing Process

In this sugar article mainly discussing about what is refined sugar, Refined sugar making process, basic steps for making refined sugar and refined sugar specifications.

Mainly sugars are classified as.

1. Raw sugar.

2. Plantation white sugar.

3. Refined sugar.

What is refined sugar

Refined Sugar is produced by sugar cane or beet via raw sugar. (i.e From sugar cane or beet, first produced raw sugar by ordinary process known as Defecation process. Then raw Sugar is following further process like melting, clarification and decolourization to produced refined sugar.)

Refined sugar Vs White sugar:

Refined sugar is better than plantation white sugar because it contain less impurities, less colour value of ICUMSA. As well as it is suitable for long time storage.

Types of Refined Sugar manufacture

There are two types of sugar refineries.

a) Refineries operating in conjunction with raw sugar factory.

b) Independent refineries which purchase raw sugar from raw sugar factories. Independent refinery called standalone refinery.

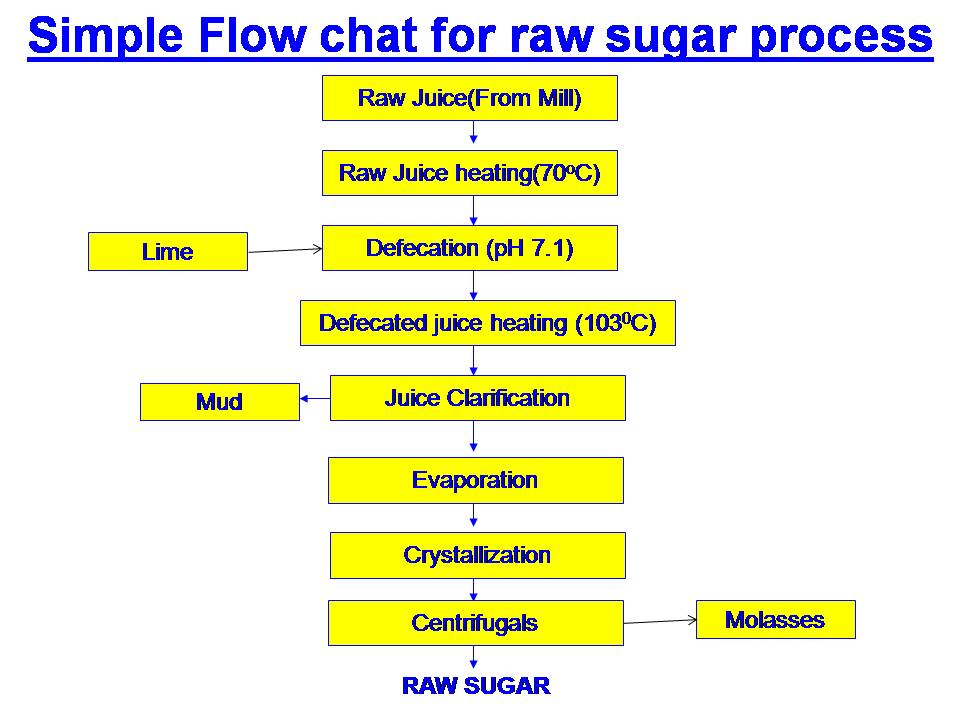

Flow Chart of Raw sugar Process from Sugar Cane

Please go through the below link for more information about raw sugar manufacturing process step by step from sugar cane

Please go through the below link for more information about raw sugar manufacturing process step by step from sugar cane

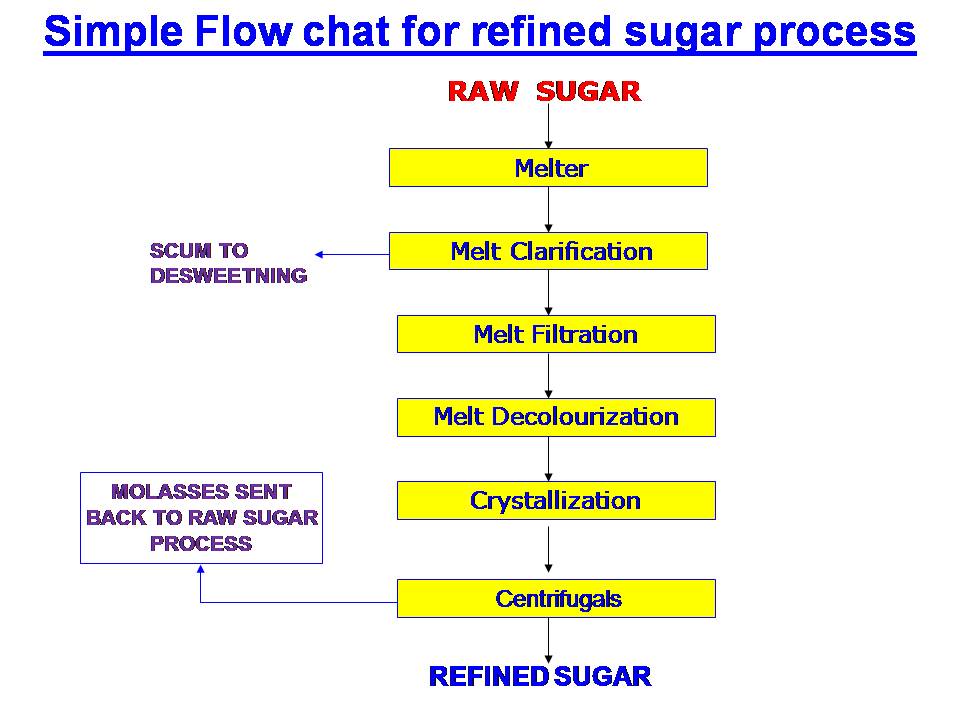

Flow Chart of Refined Sugar Process

Refined Sugar Making Process step by step from Raw Sugar

Affination:

Affination process required only for higher colour Raw Sugar(above 1200 ICUMSA colour value). For good quality of raw sugar there is no need to follow this affination process.

The main aim of affination process is to obtain affinated sugar over 99% purity & containing minimum colour and ash. In this process above 50 to 60% colour is removed mechanically depending on input colour of raw sugar.

In affination process mainly done mingling the input high colored raw sugar with affination liquor (Which is obtained molasses from the centrifuged in same process) and purging the its magma mixer in centrifugal machine with washing of hot water after the lquior has been spin off.

Affination Process in Standalone Sugar Refinery with Material balance Calculation

Melting:

The equipment which is used for melting of sugar is called Sugar Melter. Raw sugar (low colour & good quality) or Affinated raw sugar is melted in a sugar melter.

Raw sugar having the crystal size in the range of 250 to 650 micron. The retention time of melt in a sugar melter having 25 to 30 minutes and maintained 75 oC temperature. For melting of sugar used hot water or sweet water and maintained the concentration of melt liquor of 64 to 65o Brix. Some times we add enzymes of Dextron and Starch in this sugar melter. A screen is usually installed at the exit of melter.

Raw sugar melter capacity and design calculation in sugar industry

Clarification:

Clarification process helps to removing impurities and eliminates maximum colour of melt. Generally refineries are following two types of clarification processes. They are

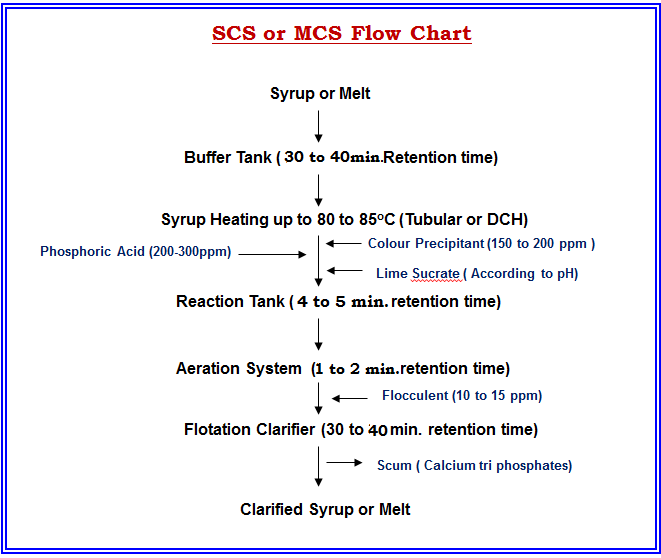

a ) Melt Phosfloatation : The Phosphoflotation process works on the principle of forming low density aggregates of particles and bubbles, and lower the density, more quickly they float.

For more information go through the below link

Melt Clarification System Design Criteria for Sugar Refinery Process

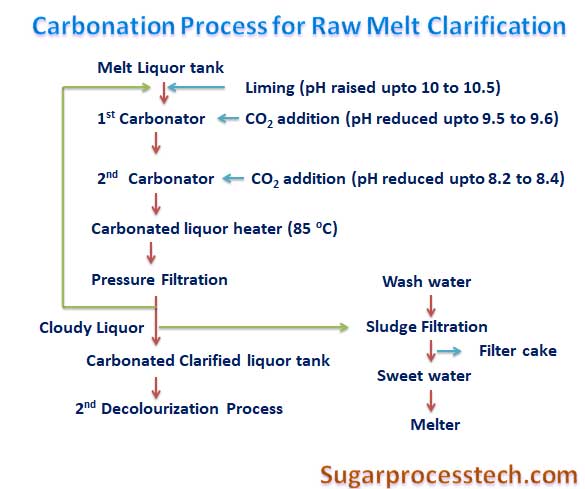

b) Melt Carbonation : This carbonation process of melt mainly having two distinct steps. The first step is the formation of a voluminous and gelatinous precipitate by reaction of calcium and CO2 and second step involves the conditioning of the precipitate in order to improve its filter-ability.

Ca (OH)2 + CO2 = CaCO3 + H2O

For more information go through the below link

Carbonation Process – Raw melt decolourization process in Sugar Refinery

In Clarification of raw melt process colour reduction will be depended on type of process. It will be around in the range of 30% to 50%

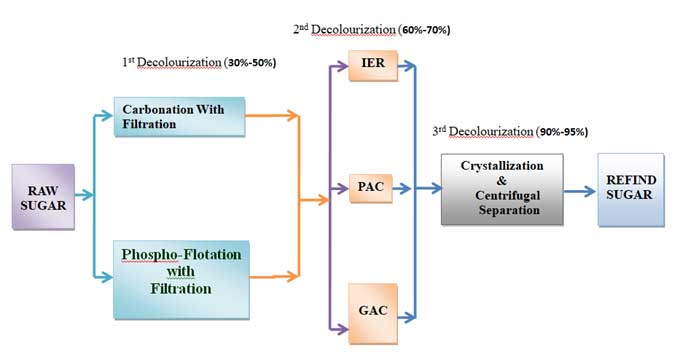

Decolorisation:

In the Secondary Decolourization process colour reduction will be depended on type of process. It will be around in the range of 60% to 70% on input of the melt.

In this process mainly three decolorization processes are there.

a) Ion Exchange Resin (IER) : Ion exchange technology is one of the most suitable processes for melt decolourization in sugar refinery and it was introduced in refineries in 1970.

The Mechanism of colour removal in the IER process consists

Ion exchange reaction in between negatively charged colorants ,Hydrophobic interaction between the non polar colorants and Adsorption inside the pores of the resin bed of colorants

b) Powdered Activated Carbon(PAC) : In PAC process consists of colouring matters is absorbed on the surface of activated carbon. These adsorbents used in single stage or double stage, depending on the color loading and effectiveness of other process stages. Filtration is a main limiting factor in this process.

c) Granular activated carbon (GAC ): Granular Activated Carbon (G.A.C.) is technically preferred as the adsorbent for removing color after carbonation. G.A.C. will also used for removal of the odor in liquor, if any.

An after burner for the stack gasses is required to eliminate odor emission problems from the furnace’s regeneration of G.A.C.

In GAC system the main disadvantage is the high sucrose loss associated with the process. The sucrose will be around 0.04% on an operating day and as much as 0.4% during the shutdown periods.

A GAC system is known to be capital cost is in higher side as compared to an IER system.

Crystalisation and centrifuging:

The fine or decolourized liquor is feeding to first massecuite and syrup separated from this massecuite is using as feed for second boiling, syrup from second boiling is feeding for third massecuite boiling, and so on. White massecuites (R1, R2 & R3 grades) are discharged from vacuum pans to enclosed receiver and then sent to white centrifugal machines for crystal and molasses separation.

For more information go through the below link

Pan Boiling Scheme, Color, Solids and Purity balance in Sugar Refinery Process

Overview of Colour reduction in Sugar refinery

Drying ,Cooling :

Wet sugar from white centrifugal were conveyed through hoppers for the process of sugar drying-cooling. These hoppers having hot and cold air arrangements. The sugar comes from hoppers to be maintain less than 40°C temperature and moisture having less than 0.04%. Sugar have conveyed to a vibratory screen for lump separation and then followed by gradation process in sugar grader.

Sugar Packing:

Sugar from bins automatically weighed and filled in bags and sewn in automatic or manual sewing machine. Packed bags have transported by belt conveyor to sugar warehouse and stacked manually or automatically.

Specification of Refined Sugar:

Refined Sugar Specifications (II REVISION) In INDIAN STANDARD IS 1151:2003 |

||

| Sr.No. | Characteristic | Requirement |

| 1 | Loss on drying %by mass (Max) | 0.05% |

| 2 | Polarization (Min.) | 99.7 |

| 3 | RS% by mass (Max) | 0.04 |

| 4 | Conductivity Ash% by mass (Max) | 0.04 |

| 5 | Color ICUMSA unit (Max) | 60 IU |

| 6 | SO2 Content mg/kg (Max) | 15 PPM |

| 7 | Lead mg/kg (Max.) | 0.5 |

| 8 | Chromium mg/kg (Max) | 20 |

Specification of Refined Sugar as per European Economic Community (EEC) – sugar grade |

||||

| Sr.No | Characteristic | EEC1 | EEC2 | EEC3 |

| 1 | Pol % (min) | 99.7 | 99.7 | 99.7 |

| 2 | Moisture % (max) | 0.06 | 0.06 | 0.06 |

| 3 | RS % (max) | 0.04 | 0.04 | 0.04 |

| 4 | Ash % (max) | 0.011 | 0.02 | NS |

| 5 | Color % (max)in ICUMSA | 22.5 | 45 | NS |

Hi friends thank you for read my article “Refined Sugar manufacturing Process”. If you like this article please share it.

Relative Topics

Description of Syrup Clarification System and Melt Clarification System

Methods for Decolourization of Raw melt

Design Criteria for Melt Clarification System

Carbonation Process in Sugar Refinery

Colour, solid and purity balance of massecuite boiling of Refined sugar

Material Balance Calculation for three massecuite Boiling

Know About How Many Types of Sugars Available like raw sugar, refined sugar, white sugar, jaggery

Liquid Sugar Manufacturing Process from sugar cane | Liquid Sucrose

29 thoughts on “Refined sugar making process | Flow chart and Specifications”

P.Bhaskat

(August 16, 2017 - 5:09 pm)I required refund sugar international standards chart

Somvir singh

(January 29, 2019 - 11:15 am)R/sir,

Please you send refined sugar

Process chart my email I’d

With regards.

siva alluri

(January 29, 2019 - 2:51 pm)Ok we will provide

mohammed ibrahim altraifi

(April 1, 2020 - 6:41 am)please send me refine sugar internation standard chart

siva alluri

(April 26, 2020 - 12:05 pm)Ok we will provide soon

Romulo Huergo Gargar

(June 21, 2022 - 4:14 pm)Sir, can you give me data on steam requirements per ton of refined sugar?

Thanks

siva alluri

(June 26, 2022 - 2:23 pm)Ok we will publish article on this soon

Amesh kumar

(October 1, 2018 - 3:53 am)complete process of refine sugar from raw sugar for 5000tcd sugar factory

Ganesh Shinde

(April 7, 2019 - 2:05 pm)its very good information about refine sugar . Thanks sir .

siva alluri

(April 8, 2019 - 4:31 pm)Thank you

manoj chandel

(May 24, 2019 - 6:01 am)nice information sir

plz send the colour value in refined sugar plant from mixed juice to final molasses.

siva alluri

(May 25, 2019 - 4:34 pm)Ok we will provide ranges of colour values

Uday

(September 18, 2019 - 6:42 am)Dear sir, Please help colour balance of Raw sugar refinery

siva alluri

(September 18, 2019 - 11:01 am)ok we will prove soon

Xuzhuan

(October 3, 2019 - 10:41 am)Dear sir, Please help colour balance for refinery sugar。Thank you

siva alluri

(October 10, 2019 - 3:53 pm)Ok we will provide

Myint Than

(December 22, 2023 - 11:37 pm)Thanks.

siva alluri

(October 13, 2019 - 5:05 pm)Color, Solids and Purity Balance of Refined Sugar Massecuite Boiling

https://www.sugarprocesstech.com/refined-sugar-massecuite-boiling/

siva alluri

(October 13, 2019 - 5:05 pm)Color, Solids and Purity Balance of Refined Sugar Massecuite Boiling

https://www.sugarprocesstech.com/refined-sugar-massecuite-boiling/

RKTewari

(October 26, 2019 - 6:13 am)Pl provide complete sugar refining process for a 5000 TCD sugar mill

siva alluri

(October 30, 2019 - 3:55 pm)Please go through the below links

https://www.sugarprocesstech.com/refined-sugar-making-process/

https://www.sugarprocesstech.com/refined-sugar-massecuite-boiling/

https://www.sugarprocesstech.com/carbonation-process-in-sugar-refinery/

https://www.sugarprocesstech.com/sugar-refinery/

Is Organic Sugar Really Better For You? What You Must Know in 2020 - How to Make it Happen

(April 22, 2020 - 4:06 pm)[…] helps remove more impurities and typically this is where two different types of clarification processes are […]

Shyam tuli Shyam tuli

(June 16, 2020 - 4:39 am)SRI ram bearing corporation

dB shanmugam Street

Door number8/3

Ayanavaram

Chennai:600023

9677638786

Zahara Khan

(April 29, 2021 - 6:02 pm)WHat is cost of raw sugar processing into fine sugar ( per ton cost)

fazli shah

(March 3, 2022 - 3:52 pm)Hi.

I am Fazli from Malaysia. My company wanted to venture into sugar manufacturing (from raw sugar to white sugar (refined sugar)). Our proposal is 1500 mt per day or 45000 mt a month. Do you have idea what is the total cost?

siva alluri

(March 24, 2022 - 4:14 am)This website only providing the basic idea about sugar industry equipment and latest technology developments in sugar manufacturing

Aso. Abdulkhaliq Aziz

(April 25, 2022 - 12:05 pm)Dear Sir ,

I am investor in kurdistan north of Iraq, I have proposal to establish white crystal sugar factory, according to my researches the production of 40 metric ton for 24 HRS is enough for the starting , I need offer for all machines from receiving beets to crystal sugar , please kindly send me the offer I will continue with your company , and I am ready to sign the contract please fell free if you have any question or more clarification here is my email address (Aso.aziz20@gmail.com ) ) WhatsApp (00964 750 465 4264)

Bharat maruti Kshirsagar

(September 20, 2022 - 9:22 am)Pan Boiling Books Pdf please

Somvir singh

(September 9, 2023 - 10:02 am)Sir,

I am doing job in Mandya sugar Mysore Karnataka India

And I wants to job in refinery please refinery flow diagram,(I ER) send my I’d with regards