Condensate or Duplex Heater (Liquid- Liquid Heater) Design Calculation formulas with online calculation sheet

• According to the in the energy conservation point of view Sugar process industry used liquid liquid heaters for raw juice heating . It is also called condensate heater or duplex heater( for specific design).

• In liquid- liquid heater raw juice heated with process condensate water and It having two types of designs.

1 . One is normal multi passes arranged in single tube plate design and it located horizontally or vertically. Generally for condensate heaters have located in horizontal position because in the horizontal position heat transfer coefficient having high and also in this design will get proper baffle plate arrangement to the passing of hot fluid(Condensate).

2. Another design is called Duplex heater. In this type design will get maximum heat transfer coefficient upto 1200±50 Kcal/m2/hr/oC. When compare to another liquid liquid heater design its having higher heat transfer value , because the passing of hot and cooled fluid is perfectly in counter current direction from entry to leave the heater. Another advantage is high flexibility to proved spare heater or expansion the capacity of heater. In Duplex heater also flexible to collect the condensate (heating media) in different stages as per our process requirement.(i. e as per our required temperature we will get condense in middle stage of heater).

In sugar process industry while using vapour or steam as a heating media than formulas used for heat transfer coefficient and for evaluate heating surface used

. But in condensate heater calculation both are not applicable.

In this article explain about calculation of condensate heater heating surface.

Please go through the below link for heat transfer coefficient calculation of liquid liquid heater.

Heat Transfer Coefficient of Liquid -Liquid Tubular Heater

Required data for calculation heating surface of Liquid Liquid heater

1.Crushing rate = m in T/hr

2. Juice % cane = P

3. Velocity of Juice = Vj in m/sec

4. Juice inlet temperature = ti in oC.

5. Condensate Inlet temperature = Ti in oC.

6. Condensate Outlet temperature requirement =To in oC.

7. Specific heat of juice = Cp in Kal/Kg

8. Legment = Lg in mm (Generally Legment taken for Juice heater 12mm, and for evaporators will take 10mm)

9. Tube OD = OD in mm

10. Tube Thickness = Tk in mm

11. Tube length = L in mm

12. Tube plate thickness = Tp in mm

13. Total Quantity of Condensate water percent on Mixed Juice = W

14. Heat transfer coefficient = K in Kcal/m2/hr/oC.

(Note : For Dulex Heater this value lies 1200±50 Kcal/m2/hr/oC and for Normal condensate heater with proper baffle plate arrangement lies 1000±50 Kcal/m2/hr/oC)

15. Proportional factor = β in mm

Steps in Calculation of heating surface for Liquid Liquid heater:

Quantity of juice to be heating = M = m x P/100 in T/hr

Quantity of heating media (Condensate) = Q x W/100 in T/hr

Fundamental formula :

1 . Heat received by one = Heat rejected by another.

2. M x Cp x (to – ti) = Q x Cw x (To- Ti) Note : Here Cw = specific heat of heating media, for condensate it will take value 1)

3. Juice outlet temperature = to ( From the above formula it can be find out the final juice outlet temperature)

Heating Surface :

For heating surface calculation M x Cp x ΔT = S x K x ∆Tm

Heating Surface =S = [Q x Cp x ∆T]/ [ K x ∆Tm]

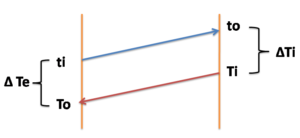

Here ∆Tm called as logarithmic mean temperature

∆T = to-ti

∆Ti = Ti-to

∆Te = To-ti

Number of tubes per pass & Number of passes:

(Note :while calculating the area of tube take mean dia of tube i.e Tube OD – Tube Thickness)

No. of tubes Requirement = N = S/ [π x Mean dia of tube x Tube effective length]

Number of passes = n = N / number of tubes per pass

In design point of view number of passes always should be even. According to this principle we consider the passes in even number. After the above consideration again calculates the actual heating surface and velocity of juice, it may be differ from required heating surface.

Pressure Drop and Tube Plate area calculation:

Pressure drop across the juice heater

Here pressure drop in MWC , n = number passes , U = actual velocity of juice (after considering the even passes), L = Length of the tube, D = ID of the tube (Note : L & D to be take same units)

Tube Plate Area

2. Tube Pitch (P ) = OD of the tube +Legment of the tube + tube clearance+hole clearance

3. Proportional factor(β) = Generally β value taken for multiple pass(i.e Juice heaters) 0.6 to 0.8 and for single pass(l.e evaporators or single pass duplex heater) 8 to 1.0.

4. Number of tubes will take as per the type of the heater. Suppose

For multi pass heater no. of tubes = Total number of tubes and

For Duplex having two pass in each section than no. of tubes = No. of tubes per pass x 2

For Duplex having single pass in each section than no. of tubes = No. of tubes per pass

(Note :Generally take extra dia in percentage on area occupied for tubes in tube plate for partition plates arrangement, free withdrawal of condensate and noxious gases removal purpose. Its value lies in the range 10 to 20% on area occupied for tubes.)

Heating media (Condensate water) inlet and out line dia :

1. Both inlet and outlet will take same dia meter.

2. Area required for condensate water entry (m2) =Quantity of heating media ( Q ) in M3/sec / Velocity of Condensate water in m/sec. (Note : Velocity of condensate will take 1.8 to 2.0 m/sec while coming from the pump )

3. Dia of the condensate water in mtr = SQRT [ (Area required for condensate water in m2 x (4/π ) ]

Remaining all design parameter can be calculated as same as the normal juice heater calculation.

Online Calculator for Condensate Juice Heater (Duplex) Basic Design

Related Articles:

Fundamental theory of Overall Heat Transfer Coefficient (OHTC)

Overall heat transfer coefficient for shell and tube heat exchanger

How to find Condensate Juice Heater Heat Transfer Coefficient Calculation

Heat Transfer Coefficient calculation of Liquid -Liquid Tubular Heater

Design Calculation of Juice Defecator and Sulphitor with online calculator

Shell and Tube Multipass Heat Exchanger Design | Tubular juice heater design calculation with online calculator

Condensate Receiving Tank Design Calculation | Condensate Mound

Flash Vapour Calculation | Flash Vapour Recovery Vessel Design Calculation.

Hi friends Thanks for reading. I Hope you liked it. Give feed back, suggestions, comments and please don’t forget to share it

23 thoughts on “Liquid- Liquid Heater (Condensate or Duplex juice Heater) Calculation”

Mukesh gupta

(June 18, 2017 - 5:32 am)Sir, I want to know, how to calculate HTC in case of DUPLEX heater. I think, rate of heat transfer in duplex in low in comparison of other heater. Another opnion, U prefer vertical type or horizontal type. Sir, please suggest me

siva alluri

(June 18, 2017 - 4:35 pm)For calculation of HTC :

Estimate overall heat transfer coefficient

1/U = 1/hi + 1/ho + Th/Km + 1/Uis

U = Heat transfer coefficient

hi= Tube inside juice film coefficient

ho= Shell side vapour film coefficient

Km = Thermal conductivity of material

Th = Thickness of the tube

Uis = Tube inside and outside scaling factor but generally consider inside scaling factor only while heating media is water vapour because tube outside not consider due to it is negligible for vapour side.

For more information please refer

CHEMICAL ENGINEERING by Coulson & Richardson’s (VOLUME 6) page no. 662 onwards

When a saturated vapour such as steam, transmits its heat to a metal surface and is condensed, the condensation may takes place in either of two entirely distinct forms. One is film type condensation, in which the condensed liquid wets the surface on which it is condensing and forms a continuous film of condensate. If the condensations occurring on the outside surface of horizontal metal tube (a very common case) this film of condensate drops off the underside of the tube: it runs down the condensation is drop wise condensation. In this case the condensed liquid does not wet the surface, but collects in drops that may range from microscopic size up to drops easily seen with the naked eye. These drops grow for while and then fall off the surface, leaving an apparently bare area in which new drops from.

For the case of vertical tube in true film type condensation on which there is considering a saturated vapour, free from any NCG and moving at low velocities,

Nusselt has derived the following equation

For vertical tubes

![ho =0.943 \ \left [ \frac{Kc^{3} \times \rho c^{2} \times g \times\lambda}{L \times \mu c \times \Delta T} \right ]^{0.25}](https://chart.apis.google.com/chart?cht=tx&chl=ho%20%3D0.943%20%5C%20%5Cleft%20%5B%20%20%5Cfrac%7BKc%5E%7B3%7D%20%5Ctimes%20%5Crho%20c%5E%7B2%7D%20%5Ctimes%20g%20%5Ctimes%5Clambda%7D%7BL%20%5Ctimes%20%5Cmu%20c%20%5Ctimes%20%20%5CDelta%20%20T%7D%20%5Cright%20%5D%5E%7B0.25%7D)

For horizontal tubes

Here

ho = Shell side condensate film coefficient

Kc = Thermal conductivity of condensed vapour

Ρc = Density of condensate

g = acceleration due to gravity

λ = Latent heat of vapour

D = Outside dia of tube

μc = Viscosity of condensate film

L = Length of the tube

ΔT = Temperature difference between vapour and metal (tube surface) = LMTD

If we can substitute values for same heater in the above equations than definitely we can get HTC more in horizontal type heater. So according to HTC horizontal type heater to be prefer but according to cleaning the heater, mechanical operation and space occupation point of view vertical type design is preferable. So according to our requirement we can go through the horizontal or vertical heater design.

sri winarno

(August 17, 2017 - 9:36 am)sir , I want to know drawing or skets liquid-liquid juice heater in cane sugar….(duplex heater). tanks sir

siva alluri

(August 17, 2017 - 4:21 pm)sri winarno

(August 17, 2017 - 9:37 am)sir I want to know drawing or skets liquid-liquid juice heater in cane sugar….(duplex heater). tanks sir

Ashish Verma

(November 1, 2017 - 4:49 pm)Dear Sir

Plz give capacity factor for juice heater and rotary vacuum filter

Ashish Verma NSI

siva alluri

(November 8, 2017 - 2:24 pm)Visit the below link equipment capacity factors

Sugar Industry Thumb Rules for Equipment Design Sizing

ANIL

(November 9, 2017 - 7:09 pm)Sir I want use thermifluid boiler for my Jaggery plant so pls help mi what is the boiler capacity calculated for open pan system for 35 tcd jaggery plants

ANIL

(November 9, 2017 - 7:28 pm)Sir is it possible to use of thermal fluid boilers for 35 tcd jaggery plants by using open pan ss vessel,then how to calculate boilers capacity and vessel size and limpiting pipeing size for vessel or in market any company give such setup for jaggery plant as per TCD

Sam

(May 18, 2019 - 6:12 pm)It seems correction is required for Tube plate diameter in your default 220 TCH calculation sheet. Tube plate dia. will be above 1 meter, how you have arrived 375 mm ?? This shall corresponds to 30 no. of tubes only.

Check and confirm pl. !!

siva alluri

(May 22, 2019 - 2:59 pm)Ok sam we will correct it

Sam

(May 18, 2019 - 6:20 pm)Oh ! my earlier comment was rather needs correction. As you correctly mentioned the dia of multipass is above 1 mtr.

ANIL NARAYAN GAIKWAD

(May 28, 2019 - 5:12 am)Sir,

Duplex Heater 300 sq. mtrs. H.S.A. -Qty 2 Nos. means 2 set or one each.

Please I want to detail information.

Yours faithfully

A. N. GAIKWAD

siva alluri

(May 30, 2019 - 5:07 pm)Sir your question not clear

LALIT MOHAN

(February 11, 2020 - 7:11 am)What is “SQRT” In condensate dia calculation??

siva alluri

(March 6, 2020 - 3:42 am)Square root

N.KI.Jain

(May 17, 2020 - 10:48 am)When we calculate dia of condensate line, formula is-Qty of condensate in m3/sec=0.785*d^2*v, so finding value d=SQRT(Q/(0.785*v)). Means we have to take square root of the value.

siva alluri

(June 23, 2020 - 2:44 am)Yes square root of entire value

Q = AV &

A = π r2

or

A = 0.785 x d2

N.K. Jain

(May 17, 2020 - 7:35 am)Heating surface calculation formula posted is mistyped i.e. Q in place of M. Again HS calculation checked by me is different.Can you tell me what is value of ΔTm. my value is coming 24.66 by which HS comes very less.

siva alluri

(June 23, 2020 - 3:20 am)Ok mistype corrected,

ΔTm – 21.30 for same values in online calculation sheet

N.K. Jain

(May 17, 2020 - 10:54 am)Dear sir,

For single pass duplex cond. heater, what will be HS for 12000 tcd plant for heating juice from 40 to 60 deg.C using condensate of 90 deg. qty 350 m3/hr. Actually it is 1000 m2 but in calculation it is very less 500 m2.Please clarify.

siva alluri

(June 23, 2020 - 2:43 am)How much you considered heat transfer coefficient you considered. What is required outlet temperature of condensate

HTC of condensate heater

For Dulex Heater this value lies 1200±50 Kcal/m2/hr/oC and for Normal condensate heater with proper baffle plate arrangement lies 1000±50 Kcal/m2/hr/oC

Please go through the below link for more information

https://www.sugarprocesstech.com/heat-transfer-coefficient/

K S Naik

(September 3, 2020 - 8:35 am)Dear Sir,

For single-pass duplex cond. heater, How to calculate the shell side pressure drop for the pump head calculation purpose.