How to Make Jaggery (Organic and Commercial) from sugar cane

Jaggery (Gur):

Manufacturing of Jaggery is from sugar cane followed by clarification and concentration process. It is Uncentrifuged sugar (i.e. Without separation of molasses) with minimum sucrose of 70% to 80% by mass. It is also called a Gur.

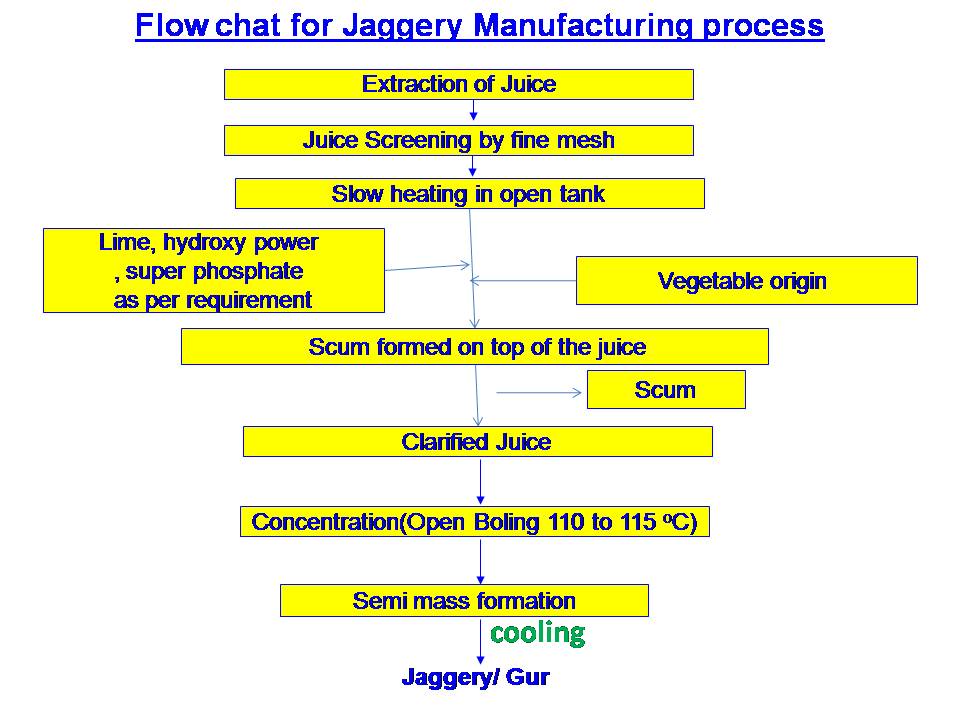

Flow Chart for Jaggery Making Process:

Main steps in jaggery making process:

Extraction of Juice

Clarification of juice

Concentration of juice

Extraction of Juice:

Generally, three roller mills are used for juice extraction. It is driven by an electrical motor or diesel engine. This extraction of juice is in the range of 60 to 70%. After extraction of juice, suspended matters are removed by cotton cloth or fine mesh screen.

Clarification of juice:

a) The sugar juice contains colloidal matter, inorganic salts, fiber, various nitrogenous substances, lipids, gums, wax organic acid, inorganic acid, pectin, etc. All these impurities were removed totally or partially in this clarification process.

b) In the clarification process generally used two types of clarificants are used they are Organic Clarificants and Inorganic Clarificants. In organic clarificants are from vegetable origin like Bendi, Sulkali, and Doela. Inorganic clarificants are used like Lime, Hydrous Power, and super phosphate.

c) The screen juice is taken in an open pan and firing starts slowly so that dissolved air escapes and gummy, colloidal substances get coagulated by the adding of clarificants as per requirement. It comes at the top surface of the juice known as scum and it is removed continuously. In this process temperature requirement is 70oC to 800

d) First added vegetable origin is simultaneously a small quantity of lime water added to reduce the acidity of juice but not to the extent to make juice neutrals because the taste and colour of gur produced will be inferior. In this lime process, pH maintained 6.2 to 6.5. In some cases super phosphate. P2O5, and 0.25% concentrated hydrous power are also added to obtain the good colour of Gur (jaggey). While juice temperature rises scum is removed by perforated strainers.

Concentration of juice:

After clarification is completed by vigorous boiling, the temperature of the boiling mass is around 110 to 115o Boiling takes place about 2 to 3 hours. The stage at which semi-fluid material is formed then it is transferred to rectangular boxes or Bucket shape boxes as per requirement. This mass is allowed to cool to a solid form.

Composition and specification of Jaggery (Gur):

a) It contains all the nutrients and substances present in cane juice. The nutrient value of jaggery is slightly higher than that of crystalline sugar because it contains all constituents which are generally separated in molasses in the manufacturing of sugar.

b) Recovery of jaggery in the range from 8 to 12% that depending upon the total solids in cane.

c) Jaggery is graded in the market according to the basis of color, taste, hardness, and crystallinity which is judged by visual appearance. While practically graded jaggery should be considered sucrose %, reducing sugar, moisture, and colour.

Specifications Of Jaggery |

|||

| S.No. | Characteristic | Grade 1 | Grade 2 |

|

1 |

Sucrose % by mass( Min) | 80 | 70 |

|

2 |

Reducing Sugars% by mass (max) | 10 | 20 |

|

3 |

Moisture % by mass ( max ) | 5 | 7 |

|

4 |

Water Solubility % by mass (max) | 1.5 | 2 |

|

5 |

Sulphited Ash % (max) | 3.5 | 5 |

|

6 |

Ash Insoluble in dilute HCL % by mass (max) | 0.3 | 0.3 |

|

7 |

Sulphur Dioxide In PPM | 5 | 5 |

| Note: Total Sugars expressed as invert sugar on a dry basis shall be 90% from both grade 1 & grade 2 | |||

Storage of jaggery:

Jaggery is consumed throughout the year in daily regular practice. The jaggery deteriorates faster in the monsoon season when relative humidity is more than 70%. During this season gur absorbs moisture from the atmosphere and becomes viscous and dark colour. Hence jaggery blocks are packed in gunny bags along with waterproof sheets.

Organic Jaggery-making Process:

In Manufacturing organic Jaggery takes care from growing of sugar cane. In sugar cane cultivation maximum use only natural organic fertilizers like cow dung.

The difference between organic and commercial jaggery-making is mainly in the clarification process. In organic jaggery making process used only organic clarificants and a little bit of lime to decrease the acidity of the juice. So organic jaggery colour having dark when compared with commercial jaggery.

Related Articles

Liquid Sugar Manufacturing Process from sugar cane | Liquid Sucrose

Specialty sugar products Like Cube sugar | Candy sugar | Fondant sugars.

Brown sugar, its different making methods and also given its classification and specifications.

Cocrystallization concept in sugar industry crystallization process.

Raw sugar definition, basic steps for raw sugar making process and raw sugar specifications.

Refined sugar making process | Refined Sugar Manufacturing Process

Hi friends Thanks for reading. I Hope you liked it. Give feed back, comments and please share it.

40 thoughts on “Jaggery Making Process from Sugar Cane | Gur Manufacturing”

Naveenkumar

(August 27, 2017 - 3:20 pm)Interested in setting up automatic jaggery plant. Kindly send me the details and quotation for the same

David lubega

(March 4, 2023 - 7:36 pm)I would like to establish a 30tp jaggery plan send me the quotation

Shankaragoud S Patil

(October 2, 2017 - 3:54 pm)Please send quotation of automatic plant of jaggery 50tpd

SUDHIR MUNDEKAR

(June 18, 2018 - 5:06 pm)I am planed to invest in won jiggery plant its daily jiggery capacity is 25 MT /day we continue running plant on 7 mounth

so pl give me details of project cost & required area , Manpower ,power capacity, fual option CNG /LPG/diesel/wood which is cheapest

what is processing cost per MT

Mundekar Sudhir

9970457078

ANIL

(November 9, 2017 - 7:57 pm)Interested in automatic 35 to 50 Tcd Jaggery plant kindly pls send the details and quatation my mobile number is 9960607373

sukhdeo patil

(December 29, 2017 - 11:01 am)Interested in setting up automatic jaggery plant.35- 50 TCD Kindly send me the details and quotation for the same my MOB- 9892302338 to start in Belgaum District , Karnakak

Rajeev

(January 18, 2018 - 3:51 am)Price for fully automatic plant

amar pratap singh

(August 27, 2018 - 6:29 am)Dear Sir,

I need to setup jaggery plant of capacity 10 tcd,kindly provide the quotation as well as required area with

Complete Process diagram.it will be great if you will send the DPR for the same .

Regards,

Amar

9984000068/8795690700

Sachin mane

(October 30, 2022 - 4:20 pm)Dear sir,

Please send quotation for 100tcd jaggery powder plant

sanket gulumkar

(February 12, 2018 - 2:05 pm)Please send quotation of automatic plant of jaggery

Mr Ko Min

(February 17, 2018 - 5:10 pm)Dear Sir/Madam,

My name is Mr Ko Min from Mandaly,Myanmar. I interest automatic Jaggery Plant. Can you send me quotation of Automatic Jaggery Plant for 100 ton. I would appreciate for your reply.

With Regard,

Mr Ko Min,

Managing Director,

Ever Goal Blaze Co.,ltd,

Mandalay, Myanmar.

J. S. sahil

(October 24, 2019 - 5:57 am)contact here

Chandrakant karande

(February 22, 2018 - 2:30 am)Short but sweet information I really like it.

One thing I interested in dedicated to start new project for jaggary preparation.

Can you let me know approximately budgets. How much jaggary produced from 1tone sugarcane crossing.

puneet nigam

(August 6, 2018 - 11:07 am)Dear Sir/Madam,

My name is Mr prem narayan shukla . I interest automatic Jaggery Plant. Can you send me quotation of Automatic Jaggery Plant for 100 ton. I would appreciate for your reply.

With Regard,

Mr prem naryan shukla

Managing Director,

faizabad utterpradesh -224001

puneetnig007@gmail.com

9450916318

Dilip verma

(November 20, 2018 - 2:33 pm)Pleaae provide the quatation jaggery(Gur) autimatic plant

Manoj Golhani

(August 17, 2018 - 10:56 am)Want to establish 100 TCD plant. please share quotation for that.

Deepak Bahanudas Pawart

(August 23, 2018 - 8:04 am)Dear Sir/Madam,

My name is Deepak Bhanudas Pawar . I am interested automatic Jaggery Plant. Please send me quotation of Automatic Jaggery Plant for 100 ton. I would be very grateful for your reply.

With Regard,

Deepak Pawar

Prabhat Patil

(January 16, 2019 - 4:08 pm)Respected Sir,

I’m interested in Fully Automatic/semi Automatic jaggery plant for 25TCD. Please send me the quotation for the same. Mail Id- patil.prabhat6@gmail.com

would be very grateful for your reply.

Thanks,

Prabhat patil

VILLURI p s sai kumar

(February 20, 2019 - 12:04 pm)Sir i am interested in felled. How to contact u sir.

Amol Tambe

(February 22, 2019 - 7:24 am)Dear Sir/Madam,

My name is Amol Tambe . I interest automatic Jaggery Plant.

Can you send me quotation of Automatic Jaggery Plant for small capacity range from 5 tone- 50 tones.

Also quotation of organic Jaggery Plant

I would appreciate for your reply.

With Regard,

Amol Tambe

Mech Engg.

pune

atambe061@gmail.com

whatsapp no-7507789229

siva alluri

(February 22, 2019 - 2:53 pm)Dear Sir,

It is only knowledge based website. We are not a supplier of jaggery plant

Avinash Anna Gholap

(February 28, 2019 - 11:49 am)Pl.send me process description of 10 kg per batch over 8 hrs for pilot plant.

Ramdalpat@gmail.com

(March 8, 2019 - 9:59 am)Desi gur jagery

Ramya

(March 9, 2019 - 12:56 pm)Dear sir,

how can i reduce the jaggery moisture content.

Jagannath

(August 26, 2019 - 7:18 pm)Want the price and more feedback. So kindly reply. Need more information and some of factory visit.

SK Prasad

(September 11, 2019 - 9:20 am)Dear Sir/Madam,

My name is SK Prasad . I interest automatic Jaggery Plant.

Can you send me quotation of Automatic Jaggery Plant for small capacity range from 25- 50 tones.

Also quotation of organic Jaggery Plant.

Awaiting for your reference…

Thanking you.

Muhammad Yasin Khan

(December 16, 2019 - 8:02 am)We are interest automatic Jaggery Plant. Can you send me quotation of Automatic Jaggery Plant for Gur 100 Ton or 500 TCD, I would appreciate for your reply.

With Regard,

Muhammad Yasin Khan

GM BD FEI

Laxmiprasad Date

(December 29, 2019 - 8:37 am)We manufacture automatic jaggery plants and other machinery.

98223769661

Bhuktare Nanasaheb Ganpatrao

(March 4, 2020 - 10:03 am)respected sir , I want 50 tcd automatic jaggery plant all projects

AShok Mali

(March 29, 2020 - 6:45 am)Dear Sir,

I am planning to start the 50 TCD automatic plant in Chokadi Taluka In Karanataka please send the machinery tech details with quotation and also building details please. My cel ph no is 8380043362.

siva alluri

(March 29, 2020 - 11:44 am)Dear Sir,

It is knowledge based website not a supplier of jaggary plant.

Thank you

Dhananjay Tekawade

(April 1, 2020 - 1:02 am)All types of automatic jaggery , jaggery powder plant .

Please contact me

Dhananjay Tekawade

Pune Maharashtra India

9021315349

9561095708

C N Karande

(April 29, 2020 - 10:58 am)I am intersted in Automatic Jaggery Plant. Can you send me quotation of Automatic Jaggery Plant for Gur 50 TCD, I would appreciate for your reply.

With Regard,

Asefa

(May 15, 2020 - 6:05 pm)Dear Sirs

I am planning to start the 100TCD Automatic Jaggery and related products plant that include packaging. Please advise on cost of machinery, details of project cost & required area , Manpower ,power capacity.

Best regards

akhilesh mishra

(May 16, 2020 - 8:21 am)Dear sir..

Please send me project details for setup of 100 tpd automatic jaggery plant on my e mail and WhatsApp no..+254 738595252,

Kilgors Kenya

E mail: divyagreeninnovation@gmail.com

Ajay

(October 1, 2020 - 12:31 pm)I want to set up 30-50 TCD jaggery plant in Odisha. please send me the quotation. and only mill price separate(new and used). thanks.

Siraj

(October 15, 2020 - 9:49 am)Please send me project details for setup of 100 tpd automatic jaggery plant on my e mail msirajmunir@gmail.com and WhatsApp no. +92 321 5576016

Mudassir Shahzad Sial

(April 11, 2021 - 3:08 am)I am from Pakistan

I’m planning to invest in jiggery plant its daily jiggery capacity is 10 MT /day.

So pls give me details of project cost & required area , Manpower ,power capacity, fual option CNG /LPG/diesel/wood which is cheapest

what is processing cost per MT…

Thanks dear

ANAND ATHANI

(April 30, 2021 - 7:00 am)I am intersted in Automatic Jaggery Plant. Can you send me quotation of Automatic Jaggery Plant

Rakesh Gowda

(June 2, 2022 - 4:31 pm)Hi, We have set up new Jaggery industry with land, go down, machineries in KR Pet, Mysore close to raw material sugar cane farms, any interested parties in buying it call me.

Rakesh

9591540019