Properties of Lime and its Application of Sugar Process | Equipment’s and its Capacity of MOL Preparation LIME: Lime is the one of the main important reagent in juice clarification such as defecation , sulphitation, carbonation process. The lime is the cheapest and most required clarifying agent . The consumption of lime in different process […]

Category: Capacity & EDD

Perimeter and Area Formulas for two dimensional geometrical figures

In this page provided formulas of Perimeter and Area for two dimensional geometrical figures like square, rectangle, Rhombus, parallelogram, trapezium or trapezoid, triangle, right angle triangle, ellipse, circle, sector of a circle, segment of a circle etc Formulas for Two Dimensional Geometrical Figures Square Side for square = a & Length of diagonal = d […]

Vacuum Pan in Sugar Industry | Vacuum Pan Design Criteria | Sugar Tech

In this session discuss about Vacuum Pan design criteria for crystallization process in sugar factory. Vacuum Pan Design Aspects in Sugar Factory | Sugarprocesstech The following factors which are playing an important role in design aspect of a vacuum pan. a) Incoming b) Outgoing c) Internal d) External a) Incoming 1. Heating medium (Vapour/Steam) – […]

Batch Vacuum Pan Design Calculation | Sugarprocesstech | Sugar Technology

This article discussed about 80 MT capacity batch vacuum pan design calculation of Heating surface, Number of tubes, Dia of the downtake and tube plate, Graining volume, Dia of the vapour doom, Height of the top cone, Dia of vapour inlet and outlet pipe lines , Pipe line dia of noxious gases, Dia of condensate […]

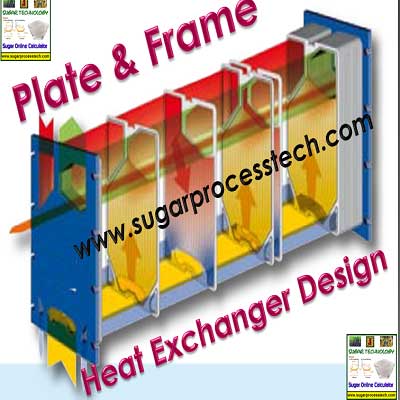

Plate Type Heat Exchanger Design Calculation | Plate and Frame Heat Exchanger

In this article explained about basic calculation for plate type heat exchange design like hot fluid and cold fluid temperatures, heat transfer coefficient, heat transfer area calculation .. etc Plate Heat Exchanger Heat Transfer Area Calculation | PHE Design Calculation Basic concepts of Plate Type Heat Exchanger : (Please go through the below link) Plate […]

Molasses Cooler Design | Molasses Preservation | Properties of Molasses

This Article summarizes the concepts of final molasses generation in process, Properties Molasses like viscosity, specific heat.Also discussed to overcome the issue of deterioration during storage. Molasses cooler design concepts and its water requirement calculation. Final Molasses Storage | Shell and Tube Molasses Cooler Design Concepts Final Molasses is one of the important & valuable […]

Sugar Melter Application in Sugar Factory | Sugar Melter design Calculation

In this article discussed about the role of sugar melter in sugar industry process house and its capacity and design calculation. Also provided online calculator for its capacity calculation. Sugar Melter Capacity Calculation | Sugar Melting Feed Liquor Calculation The sugar melter simply can be defined as it a equipment in which dissolving of sugar […]

Capacity Calculation of Pan Section in Sugar Industry | Boiling House Capacity

Pan Section Capacity Calculation in Sugar Industry | Crystallization Sugar crystallization process takes place in pan section of sugar plant. The equipment supply tanks, Batch/continuous pans, condensers, molasses conditioners, spray pond, crystallizers fall under pan section. Capacity of Batch/Continuous pans The boiling times considered for A, B & C massecuites are 3-4 hours, 4-6hours and […]

Sugar Factory Clarification Section Capacity Requirement Calculations

Sugar Plant Clarification House Capacity Calculation | Sugar Mill Here discussed about sugar mill capacity calculation for the Clarification section like pumps, juice reaction tank, lime and sulphur requirement, juice clarifier, vacuum filters … etc. 1. Raw Juice Pump Raw juice pump is also called Mixed juice pump or screened juice pump. Screen juice % […]

Unit Conversion Factors and Tables for Engineering Design Calculations

Conversion of units in Sugar Industry Equipment Design Calculations In this page provided some unit conversion factors. It will helpful to sugar industry Capacity and EDD calculations. Length Conversion Factors 1 kilometer (km) – 1000 meters (m) = 0.62137 miles 1 meter (m) – 100 centimeter (cm) 1 centimeter (cm) = 0.001 m = 0.3937 […]